Strength and rigidity testing fixture for aircraft draw bar and use method of strength and rigidity testing fixture

A technology of aircraft traction and test fixtures, which is applied in the field of stiffness test loading and aircraft structural strength, and can solve problems such as high cost, low cost, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

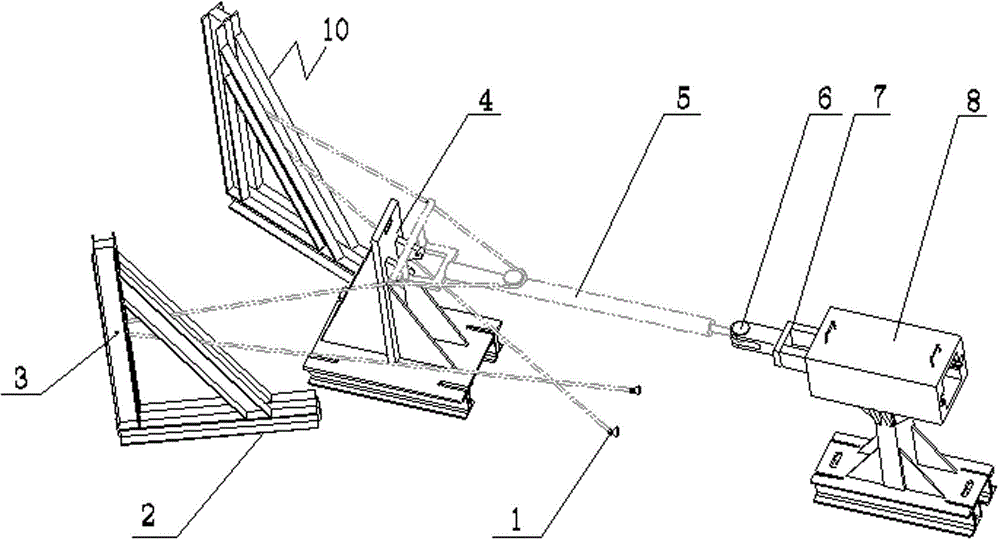

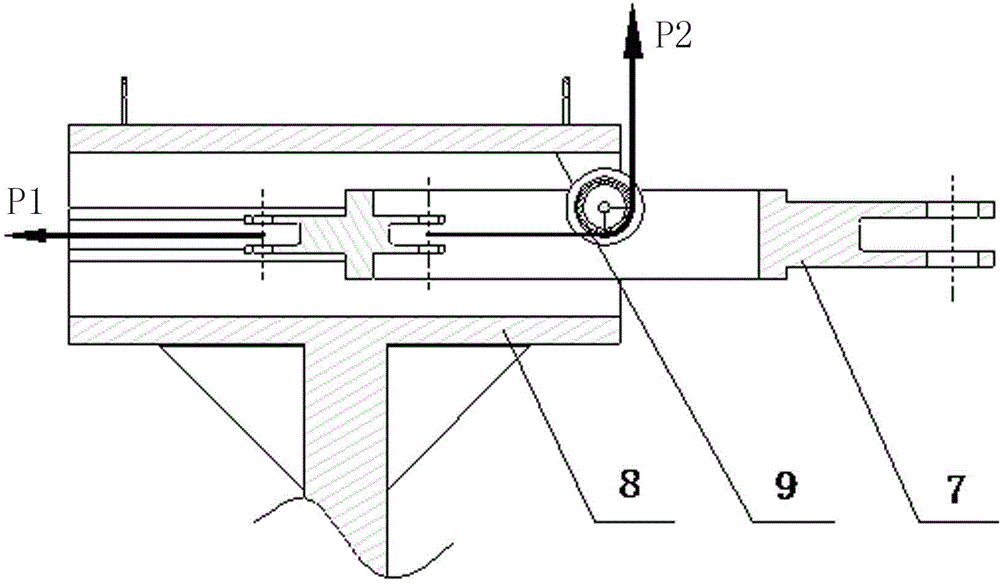

[0017] Such as figure 1 with figure 2 As shown, a kind of aircraft drawbar strength, rigidity test fixture, the front end traction ring of test piece 5 is connected with one end of main loading mechanism 7 through connecting pin 6, and main loading mechanism 7 can pass through its own bearing and slideway mechanism 8 guide rails. Sliding freely in the slideway mechanism 8, a fixed pulley I9 is set at the end of the cavity of the slideway mechanism 8, and the other end of the main loading mechanism 7 located in the slideway mechanism 8 is provided with loading joints in two directions to connect two Steel wire ropes, one is the steel wire rope pulled to the outside P1, and the other is inwardly bypassing the fixed pulley I9 and passing through the inner end of the slideway mechanism 8 along the direction of P2 force; The landing gear fixture 10, the rear end joint of the test piece is connected with the simulated front landing gear fixture 4, and the steel wire rope of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com