A kind of cu/ag/carbon nanotube composite modified glassy carbon electrode and its preparation method and application

A carbon nanotube and glassy carbon electrode technology, which is applied in the preparation of copper-silver-carbon nanotube composite modified glassy carbon electrode, catalysis and detection of nitrite in water, which can solve the difficulty of combination and affect the performance of composite materials, etc. problem, to achieve the effect of simple method, fast response and high current response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

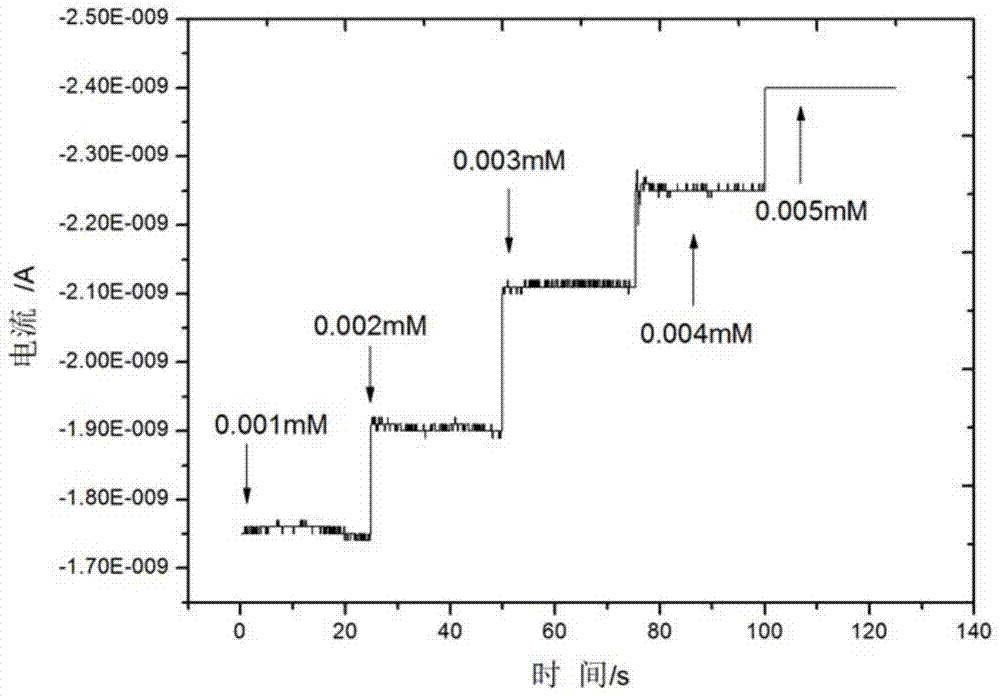

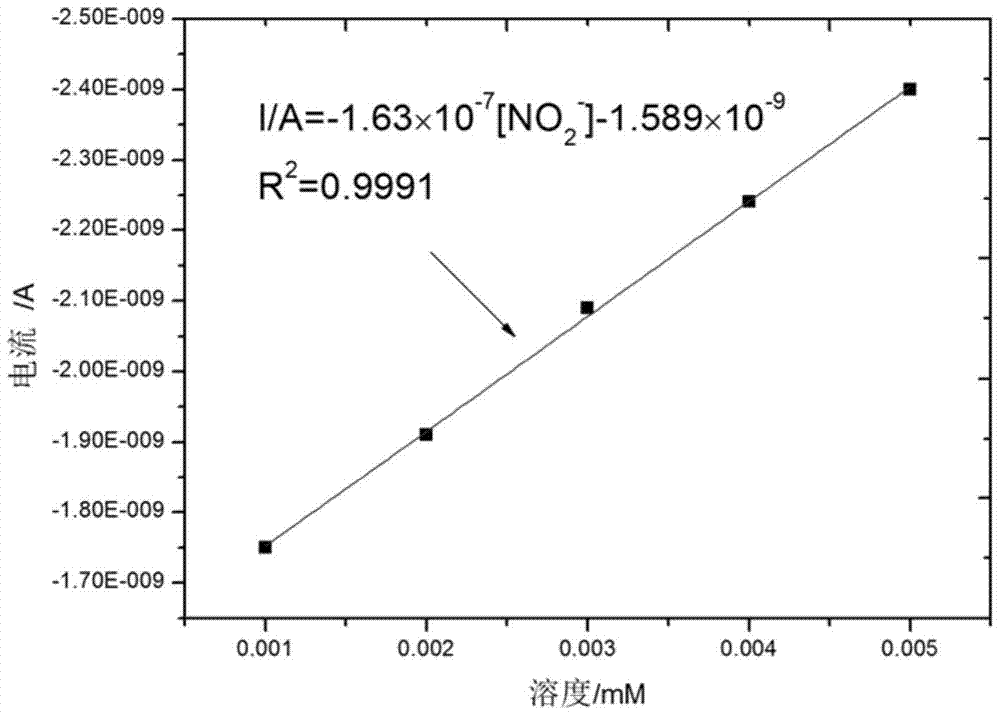

Embodiment 1

[0038] A preparation method for Cu / Ag / multi-walled carbon nanotube composite modified glassy carbon electrode, the steps are as follows:

[0039] 1) The three electrodes used in the electrolytic cell are set, and the three electrodes are composed of a clean glassy carbon working electrode, a platinum counter electrode and an AgCl reference electrode;

[0040] 2) preparing a mixed aqueous solution in which the concentration of carbon nanotubes is 0.25 mg / mL, the concentration of copper chloride is 0.01 mol / L, and the concentration of silver nitrate is 0.2 mmol / L;

[0041] 3) Put the three electrodes in step 1) into the prepared mixed solution to form a three-electrode system electrolytic cell, conduct electrodeposition with a constant potential method, and control the reaction voltage to -0.2V;

[0042] 4) After the reaction, remove the glassy carbon electrode and wash it several times with deionized water to obtain a composite electrode modified by Cu / Ag / carbon nanotubes;

[00...

Embodiment 2

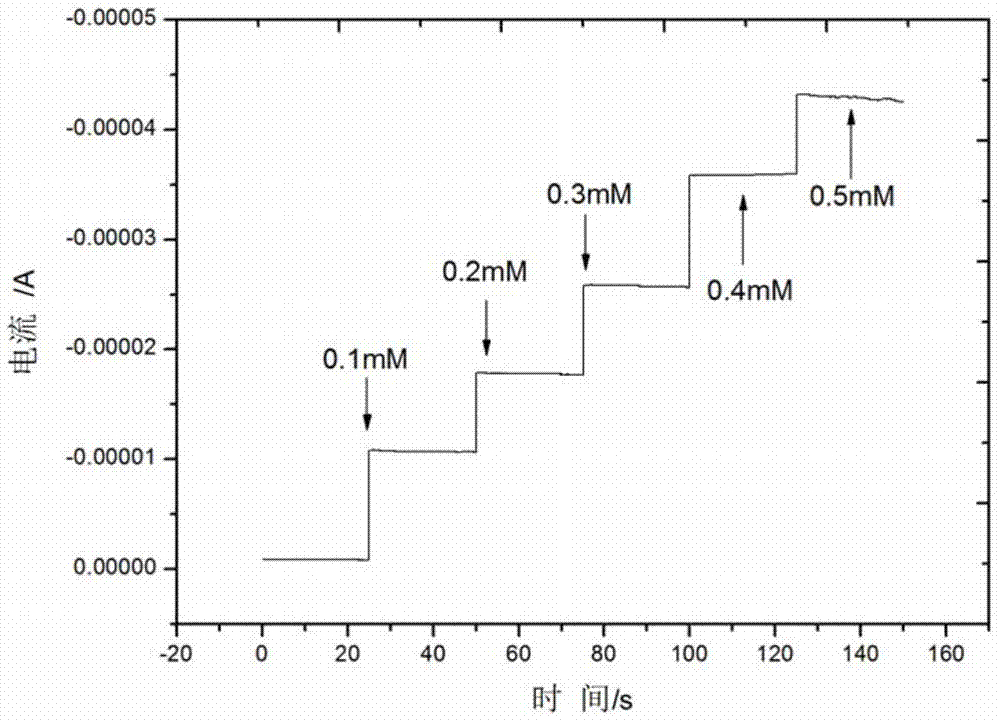

[0046] A preparation method of Cu / Ag / carbon nanotube composite modified glassy carbon electrode, the concentration of carbon nanotubes is 0.1mg / mL, the concentration of copper chloride is 0.01mol / L, and the mixed aqueous solution of silver nitrate concentration is 0.1mmol / L , the control reaction voltage is -0.1V; Others are the same as in Example 1. The detection of nitrite concentration is 1.0×10 -6 mol / L~5.0×10 -6 The response current in the mol / L range is 1.62×10 -6 A~1.76×10 -6 a.

Embodiment 3

[0048] A preparation method of Cu / Ag / carbon nanotube composite modified glassy carbon electrode, the concentration of carbon nanotubes is 0.5mg / mL, the concentration of copper chloride is 0.05mol / L, and the mixed aqueous solution of silver nitrate concentration is 0.5mmol / L , the control reaction voltage is -0.3V; other is the same as embodiment 1. The detection of nitrite concentration is 1.0×10 -6 mol / L~5.0×10 -6 The response current in the mol / L range is 5.56×10 -7 A~9.73×10 -7 a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com