Composite three-dimensional graphene electrode as well as preparation method and application thereof

A graphene electrode, three-dimensional technology, applied in the direction of electrochemical variables of materials, nanotechnology for sensing, material analysis through electromagnetic means, etc., can solve the problem of weak binding force between VMSF and three-dimensional graphene electrodes, and achieve excellent Good electron conductivity, good electron transfer performance, and the effect of improving binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of VMSF / pl-3DG electrode

[0059] 1. Preparation of three-dimensional graphene electrode 3DG

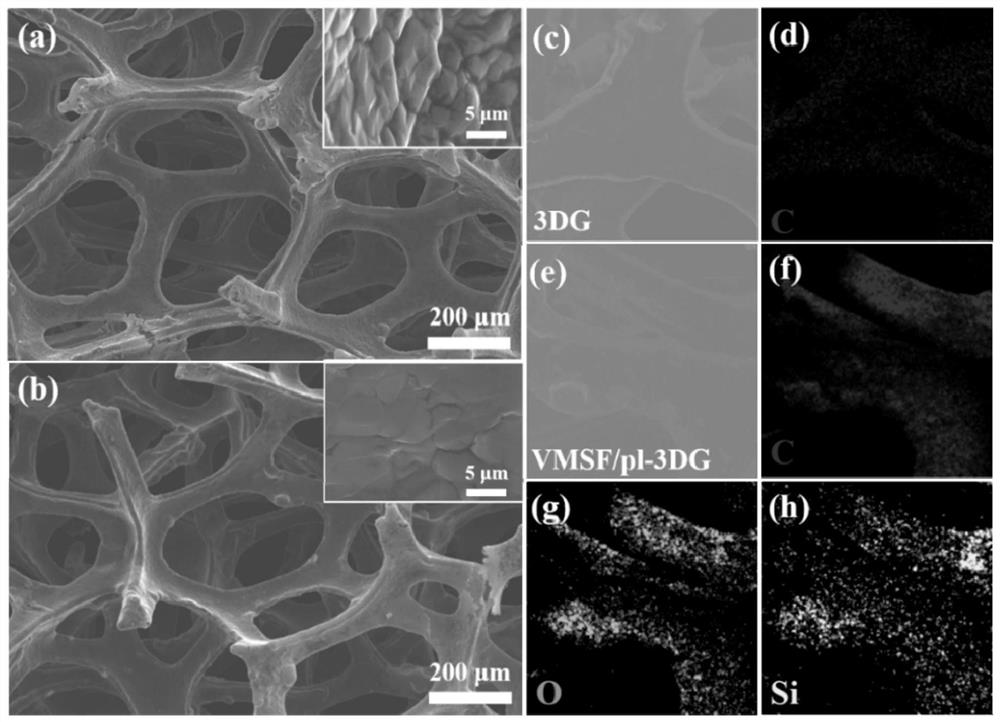

[0060] Three-dimensional graphene was prepared by chemical vapor deposition at 1100 °C using porous nickel foam as a template and methane as a carbon source.

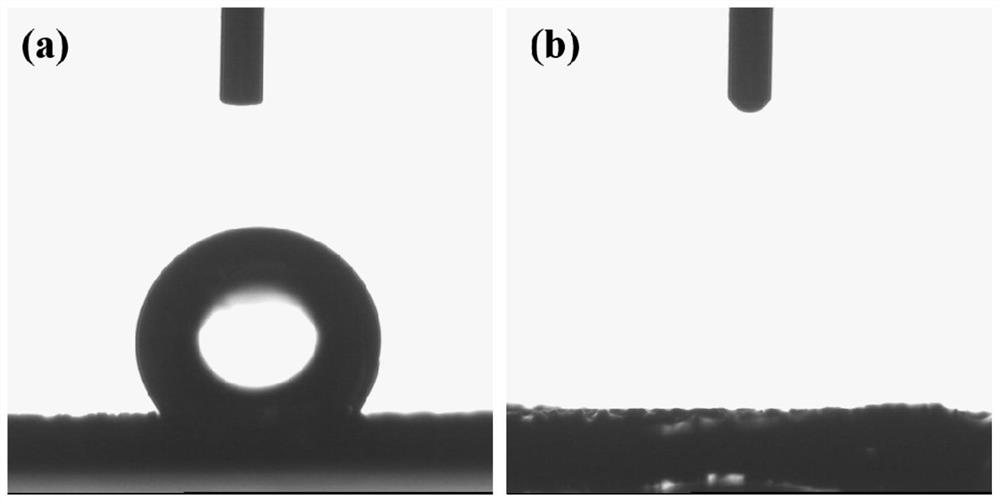

[0061] 2. Using plasma to process three-dimensional graphene, wherein the plasma is air plasma, and its generation condition is a vacuum degree of 10Pa and a power of 100W (PlasmaDyne Pro 1000s). The three-dimensional graphene electrode 3DG prepared in step 1 was placed in a plasma environment for 1 minute to obtain a plasma-treated three-dimensional graphene electrode (pl-3DG).

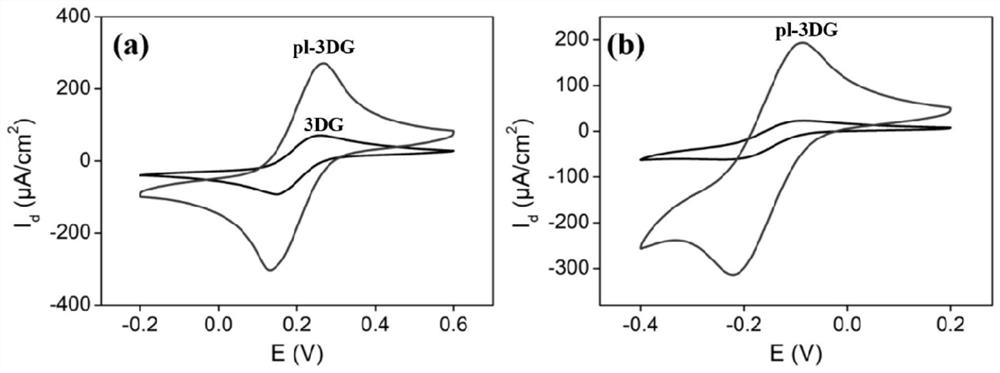

[0062] 3. Using the electrochemical assisted self-assembly method to rapidly prepare silica nanometer homoporous films on the surface of plasma-treated three-dimensional graphene electrodes.

[0063] Specifically, the precursor solution is prepared: in 20mL ethanol solution and 20mL 0.1M sodium nitrate (NaNO 3 ) solution was ...

Embodiment 2

[0083] 1. Preparation of VMSF / pl-3DG electrode

[0084] 1. Three-dimensional graphene electrode materials were purchased from Xianfeng Nano Materials Co., Ltd.

[0085]2. Using plasma to process three-dimensional graphene, wherein the plasma is oxygen plasma, and its generation condition is a vacuum degree of 12Pa and a power of 100W. The three-dimensional graphene electrode was placed in a plasma environment for 15 seconds to obtain a plasma-treated three-dimensional graphene electrode (pl-3DG).

[0086] 3. Using the electrochemical assisted self-assembly method to quickly prepare a silicon dioxide nanometer homoporous film on the surface of the plasma-treated three-dimensional graphene electrode to obtain the composite three-dimensional graphene electrode.

[0087] Specifically, the precursor solution is prepared: in 20mL ethanol solution and 20mL 0.1M sodium nitrate (NaNO 3 ) solution was added 13.6mmol TEOS and 4.35mmol CTAB, the pH of the solution was adjusted to 3.0 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com