Laser projection light source for achieving uniform no-speckle illumination

A technology of laser projection and speckle, applied in optics, optical components, instruments, etc., can solve the problems of increasing the risk of equipment damage and maintenance costs, increasing the difficulty of manufacturing and using costs, and damage to components such as circuits, so as to avoid The effect of dynamically modulating components, reducing complexity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

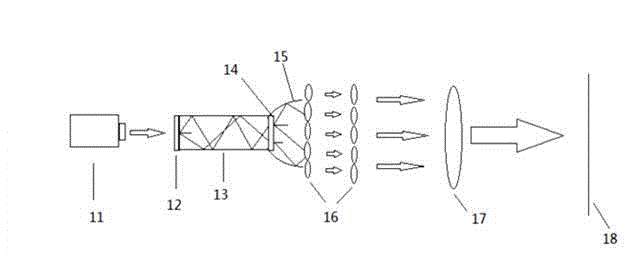

[0020] like figure 1 As shown, a laser projection light source for realizing uniform and speckle-free illumination according to an embodiment of the present invention includes: a laser 11, used for generating laser light to manufacture a light source; a first scattering sheet 12, used for beam scattering, increasing The divergence angle of the beam is enlarged, the area of the light source is enlarged, and the coherence of the beam is suppressed; the optical integrator rod 13 is used to make the light reflect multiple times in the rod, so that the energy distribution of the light field is uniform, and at the same time, the beam is further suppressed. The second scattering sheet 14 is used to scatter the outgoing light again, which increases the beam divergence angle again and reduces the beam coherence; the reflecting bowl 15 is used to collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com