Complete time delay compensation control method for chemical engineering multi-variable process

A compensation control, multi-variable technology, applied in program control, comprehensive factory control, electrical program control, etc., can solve the problems of no great improvement in control performance, compensation, and inability to perform complete time delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

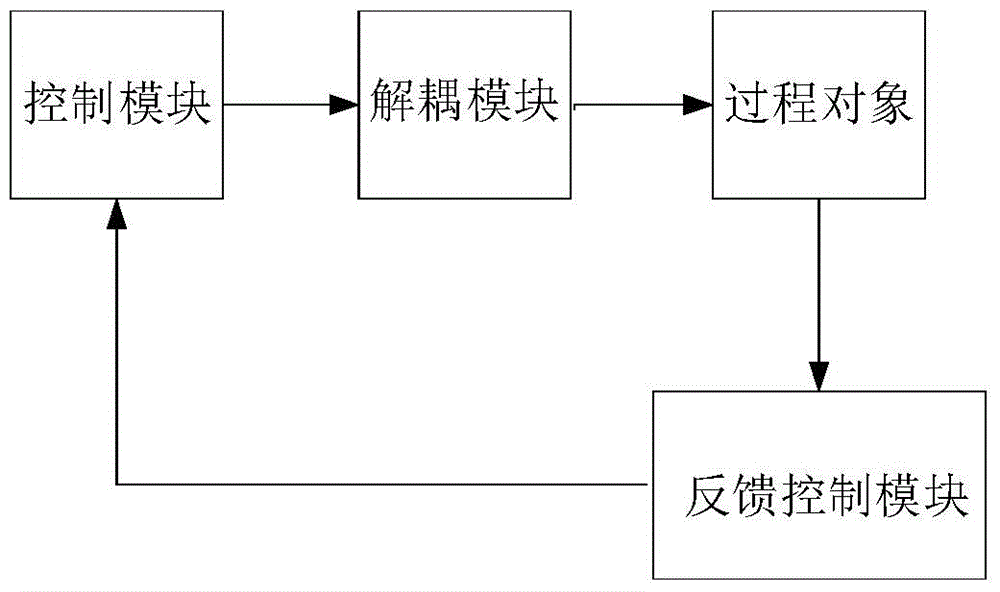

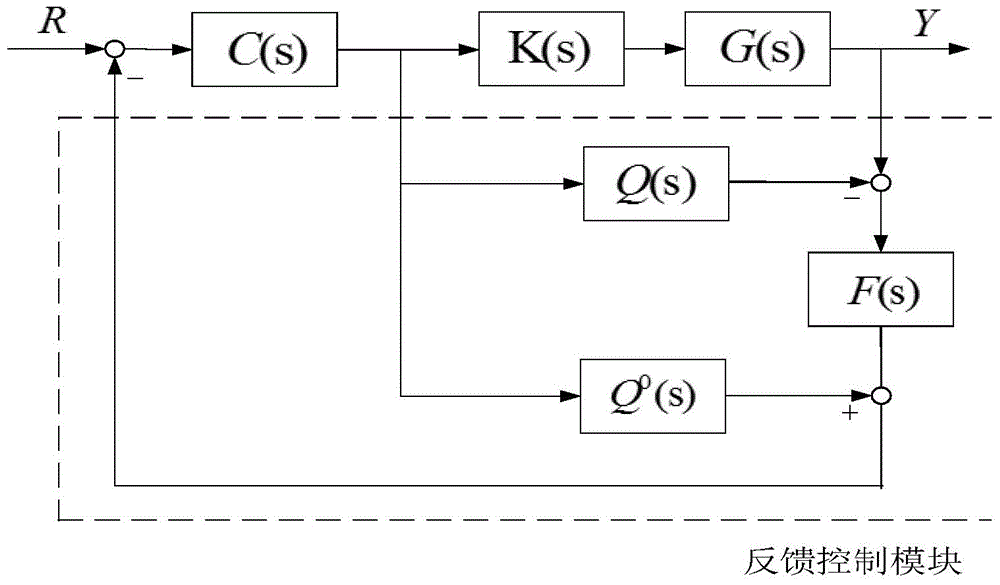

[0045] The present invention is further described in detail with reference to the accompanying drawings and simulation examples. figure 1 It is a structural diagram of a complete time-delay compensation control method for a chemical multivariable process provided by the present invention.

[0046] Firstly, a model is established for the multi-variable chemical process. The process contains n inputs and n outputs. The transfer function is expressed as:

[0047]

[0048] Among them, g ij (s) is the transfer function from the jth input to the ith output.

[0049] Observe the characteristics of the object, select the decoupled generalized object matrix Q(s), if q ii If the delay time of (s) is less than or equal to the minimum delay time of object i row, then the decoupler design is performed directly. Otherwise, considering the physical realizability of the decoupling module, add the delay compensation term:

[0050] Θ = diag { ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com