Novel recovery processing device of waste dry battery

A technology for recycling and processing dry batteries, applied in battery recycling, recycling technology, regeneration of useful parts, etc., can solve problems such as low efficiency, waste of recyclable resources, and various chemical reactions, to improve impact, improve The effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

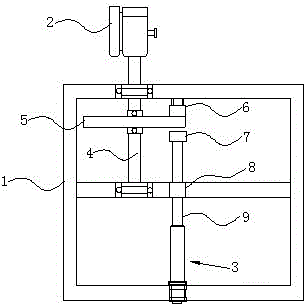

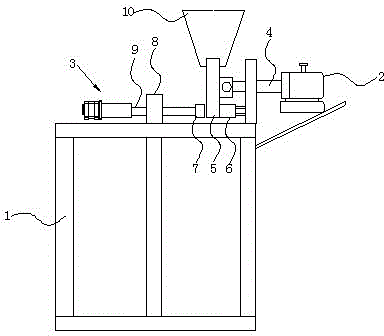

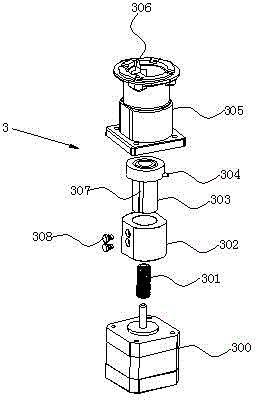

[0028] Such as Figure 1-7 As shown, it is a new type of waste dry battery recovery treatment device of the present invention, including a support frame 1, a battery casing cracking device, a sorting device, a fixed mold 6 installed on the support frame 1, and a rotatably mounted on the support frame 1 The rotating shaft 4 on the top, the first motor 2 for driving the rotating shaft 4 to rotate, the rotating wheel 5 installed on the rotating shaft 4 and synchronously rotating with the rotating shaft 4, the feed hopper 10 installed above the rotating wheel 5, and used for separating The separation device for the shell and the inner core of the dry battery 12, the transmission device 3 for driving the separation device to move forward and backward, a battery slot 14 for accommodating the dry battery 12 is formed at the peripheral edge of the runner 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com