Friction nanometer generator, generating set and power generation method

A technology of nanometer generators and generator sets, which is applied in the direction of friction generators, etc., can solve the problems that hinder the popularization and application of friction nanometer generators, and the high cost of device production, and achieve the effects of reducing production costs, improving output efficiency, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Example 1: Preparation of triboelectric nanogenerator

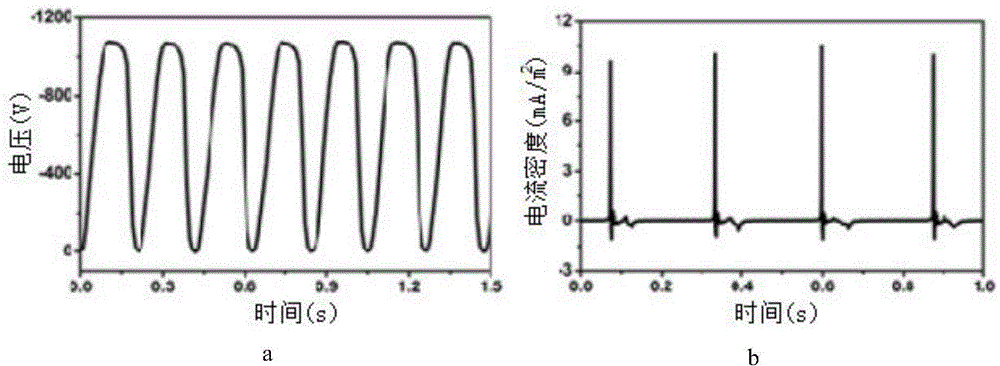

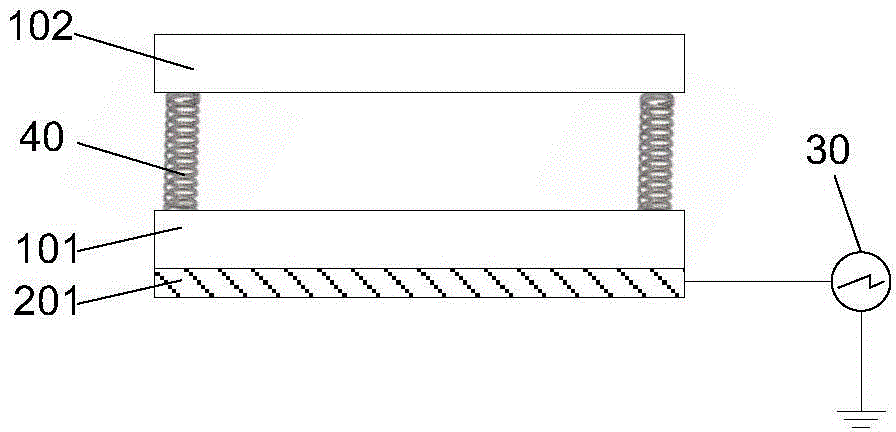

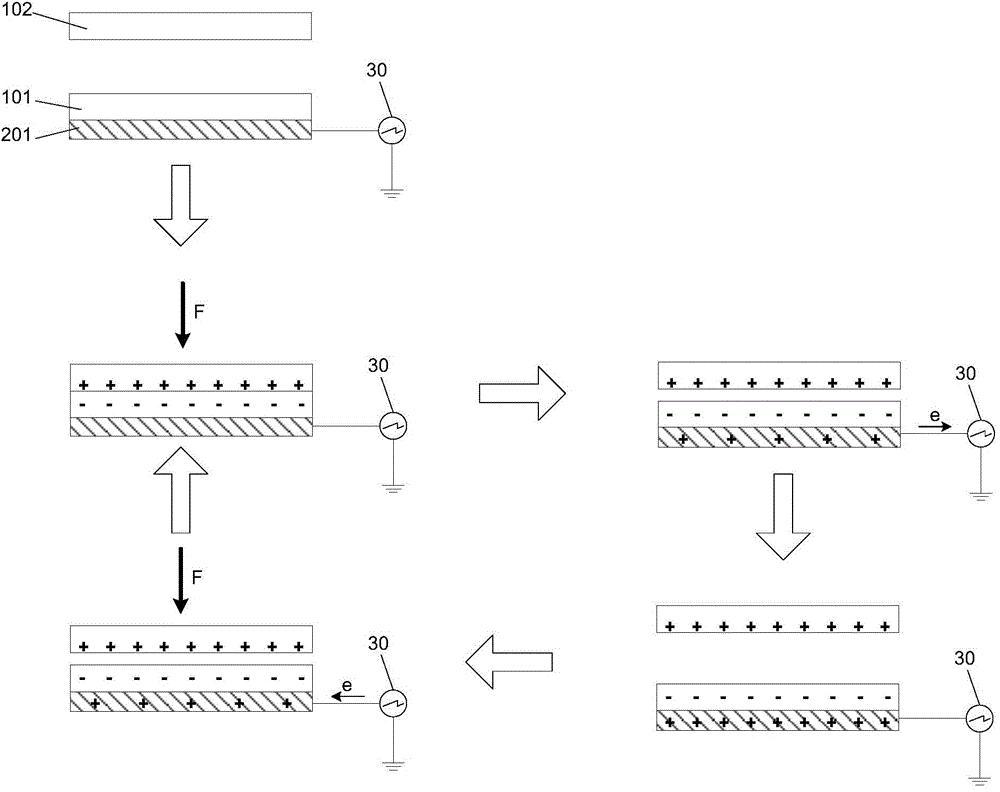

[0118] Use a laser to cut two plexiglass plates with a length of 3cm × width 3cm × thickness 1.59mm, deposit a layer of Al on the back of the polyolefin electret sheet with the same area as an electrode layer, and lead it out through a wire and pass through a monitoring element and then ground , and then stick it on a plexiglass plate to expose the polyolefin surface; stick a piece of Al foil on another plexiglass plate so that the Al foil is opposite to the polyolefin surface. The contact and separation between the Al foil and the polyolefin surface is controlled by external force, and the monitoring element displays an electrical signal output. Figure 18 -a is the open circuit voltage diagram, Figure 18 -b is the short-circuit current density signal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com