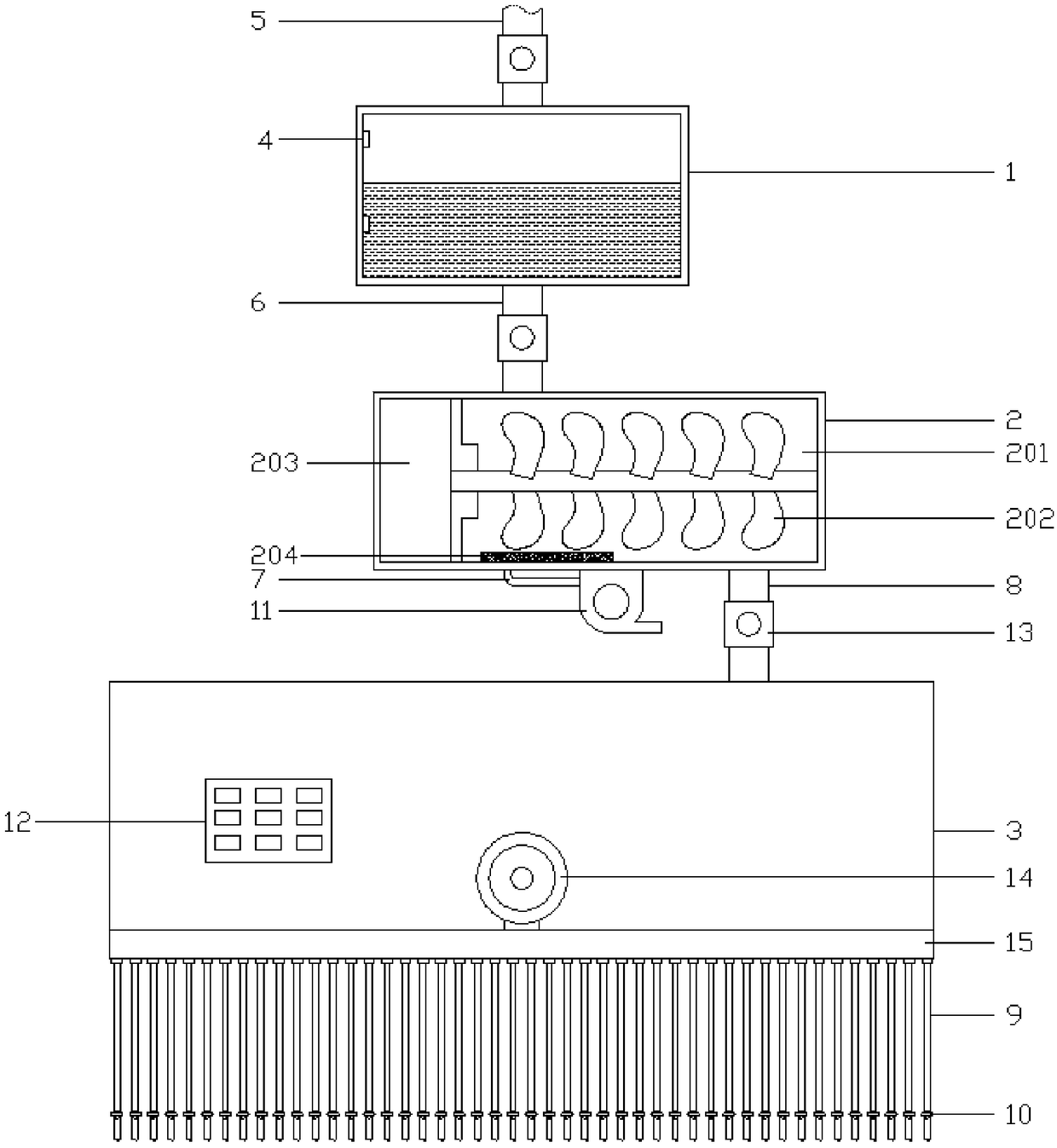

Microbubble conveying device

A conveying device and micro-bubble technology, applied in transportation and packaging, components of pumping devices for elastic fluids, mixers with rotating stirring devices, etc. , Increased energy consumption and other issues, to achieve the effect of simple and reasonable structure, novel design and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

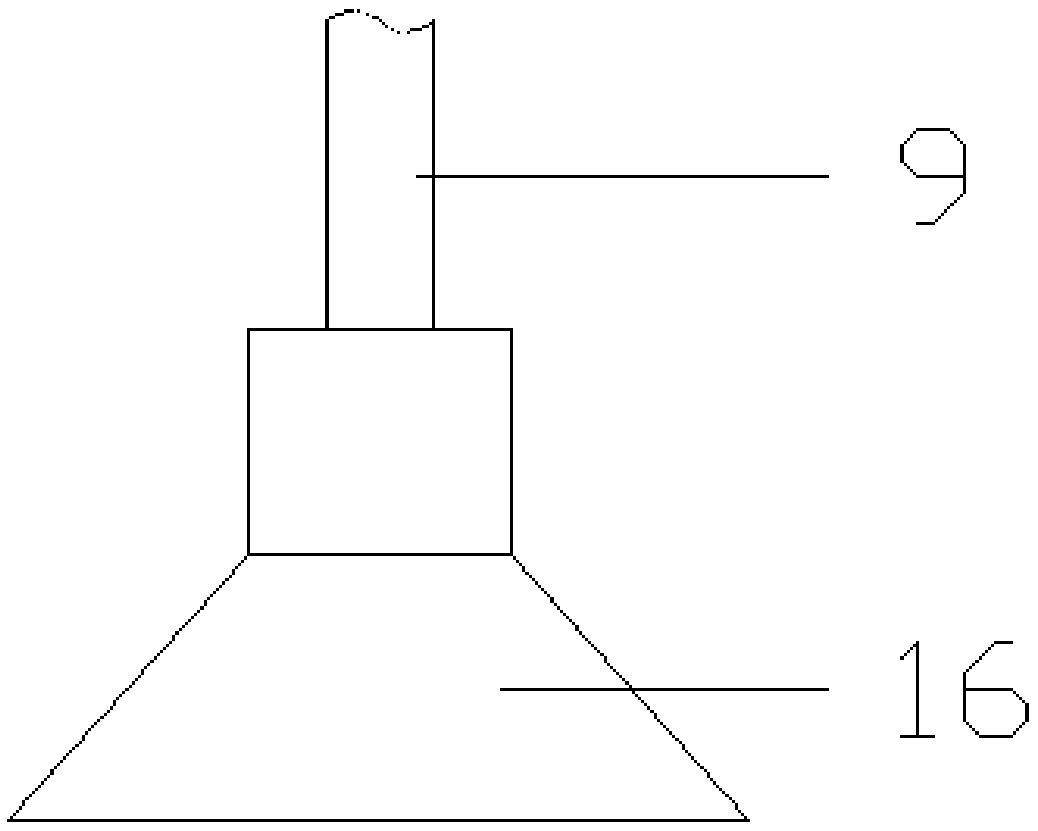

[0034] In practical application, water is controlled by the water inlet pipe 5 and enters the water tank 1 through the solenoid valve 13, and the water level sensor 4 senses the water level in the water tank 1. When the water level is too low, the controller controls the solenoid valve to open and inject water into the water tank; The water is injected into the micro-bubble machine 2, and the micro-bubble water of high density is produced by the micro-bubble machine 2, wherein, the air pump 11 inputs the outside air to the air stone 204 through the air inlet pipe 7, and a large amount of micro-bubbles are generated by the air stone 204 to In the water cutting chamber 201, the motor 203 drives the air diffuser 202 in the water cutting chamber 201 to make the air diffuser 202 rotate at a high speed, and the input air is continuously cut and injected into the micro-bubble machine 2, thereby generating several high-density bubbles. Inject high-density microbubbles into the microbub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com