Method, system, and composition for producing oil

A technology of composition and polymer, applied in drilling composition, chemical instrument and method, earthwork drilling and other directions, can solve problems such as infeasibility of oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

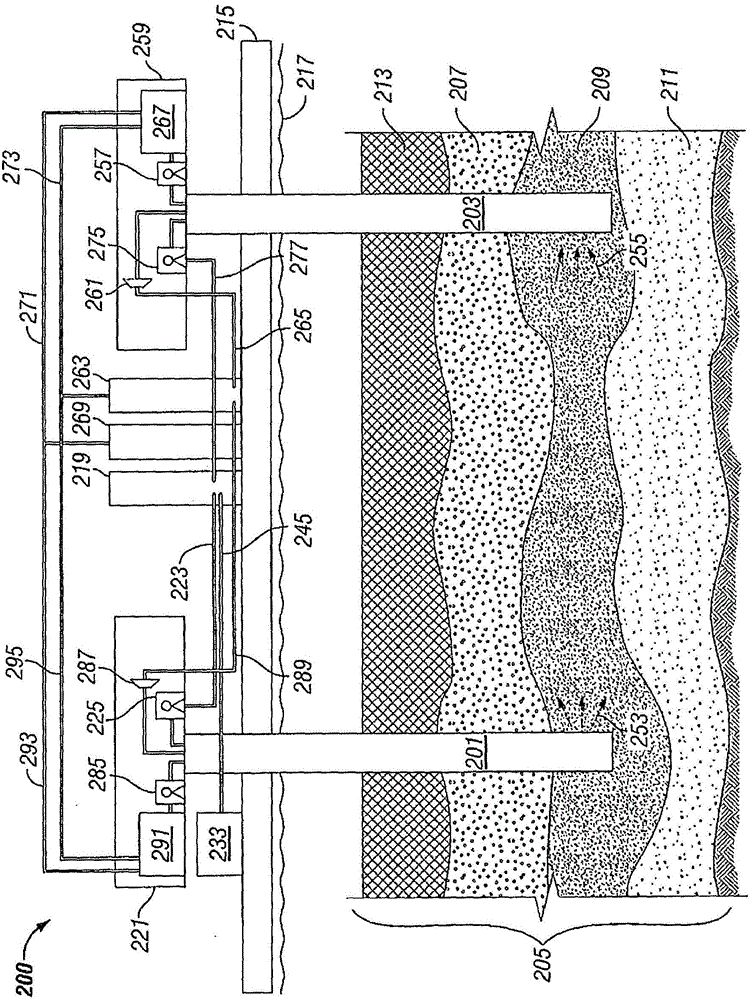

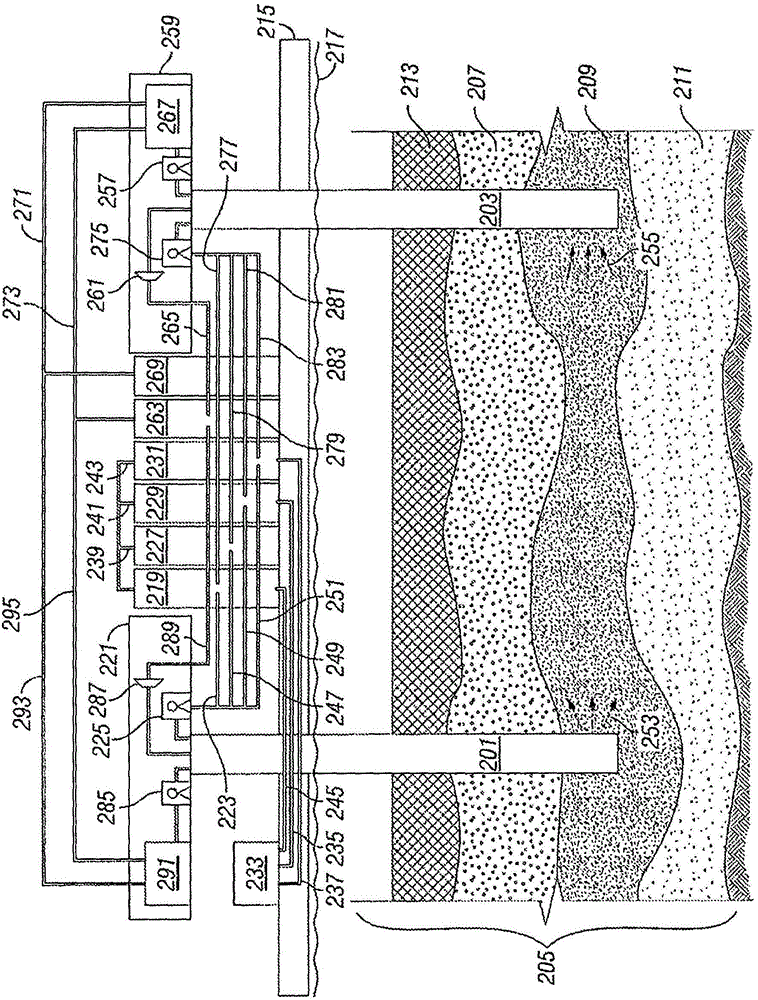

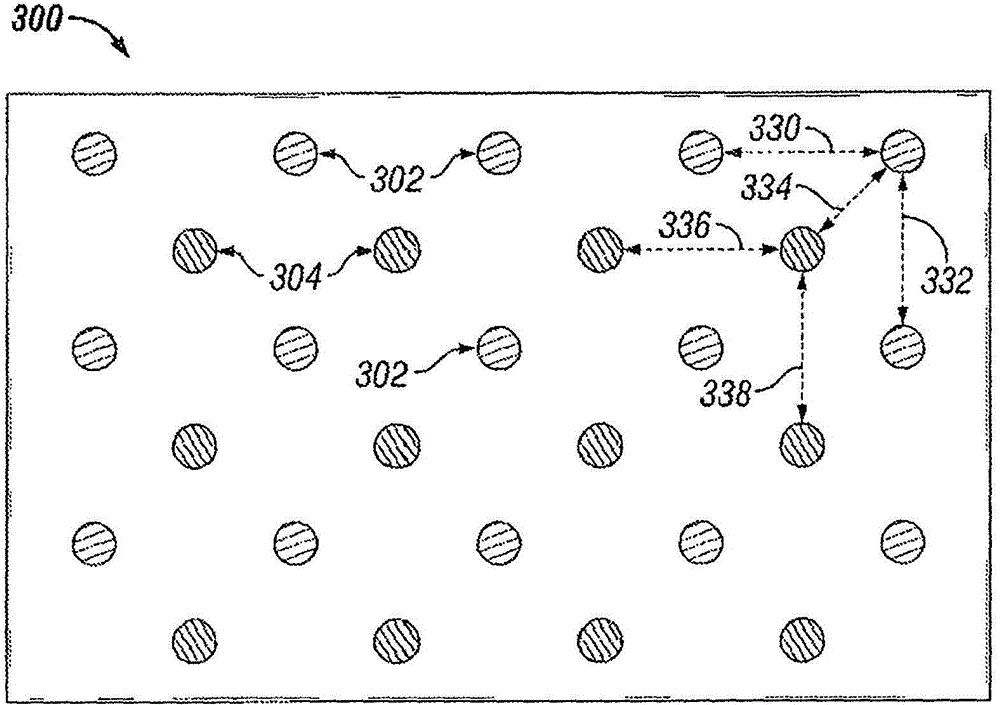

Method used

Image

Examples

example

[0087] Oil recovery flooding using the method and system according to the invention using the composition according to the invention is carried out. Experiments were conducted to determine the effect of using an ammonia-surfactant-polymer formulation on the recovery of residual oil from a formation. Sand packs were prepared by filling 2 inch diameter glass cylinders with 80 to 120 mesh sand. The sand pack is then placed under vacuum and driven with a synthetic reservoir brine solution. The sand pack was then set up vertically in an oven at 69°C and saturated with low viscosity (1.2 cp at 69°C) crude oil from the top of the sand pack until no more water was produced when further oil was introduced into the sand pack. To simulate oil production from a sand pack waterflood, the sand pack was driven from the bottom of the sand pack with a synthetic brine solution at a rate of 1.0 m / day until no more oil was produced from the sand pack. With these techniques, oil saturation and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com