Fault Isolation and Recovery Procedures for Electrohydraulic Valves

An electric and fault technology, which is applied in the direction of electric fluid pressure control, non-electric variable control, transportation and packaging, etc., can solve the problem of fault isolation protocol execution danger and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Various embodiments will be described in detail with reference to the drawings, wherein like reference numerals represent like parts and assemblies throughout the several views. Reference to different embodiments does not limit the scope of the appended claims to these embodiments. Furthermore, any examples given in this specification are not intended to be limiting but merely to present some of the many possible embodiments for the appended claims.

[0022] General Architecture Overview

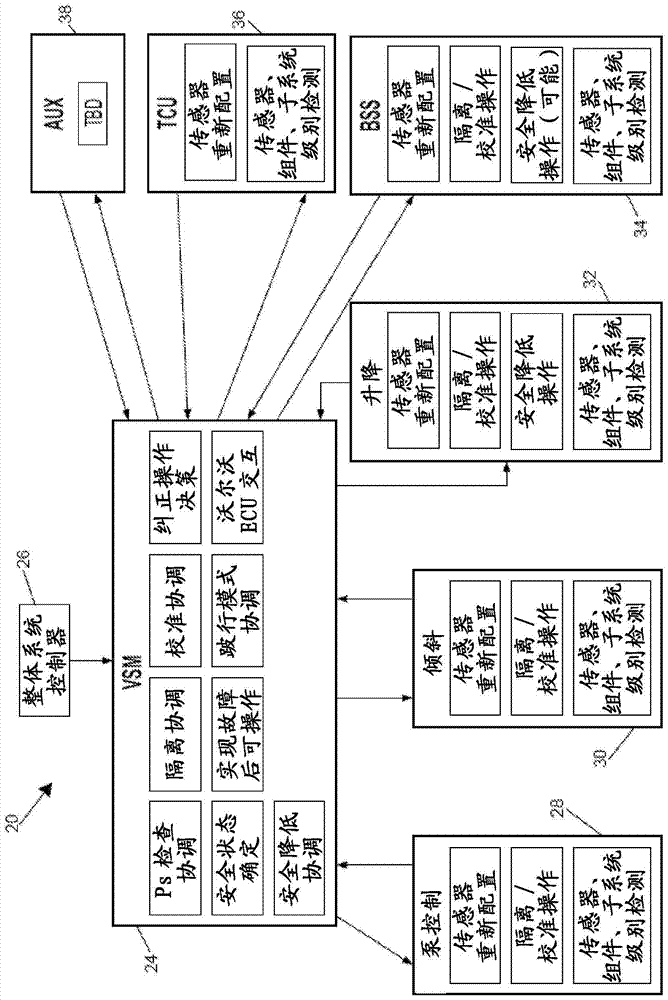

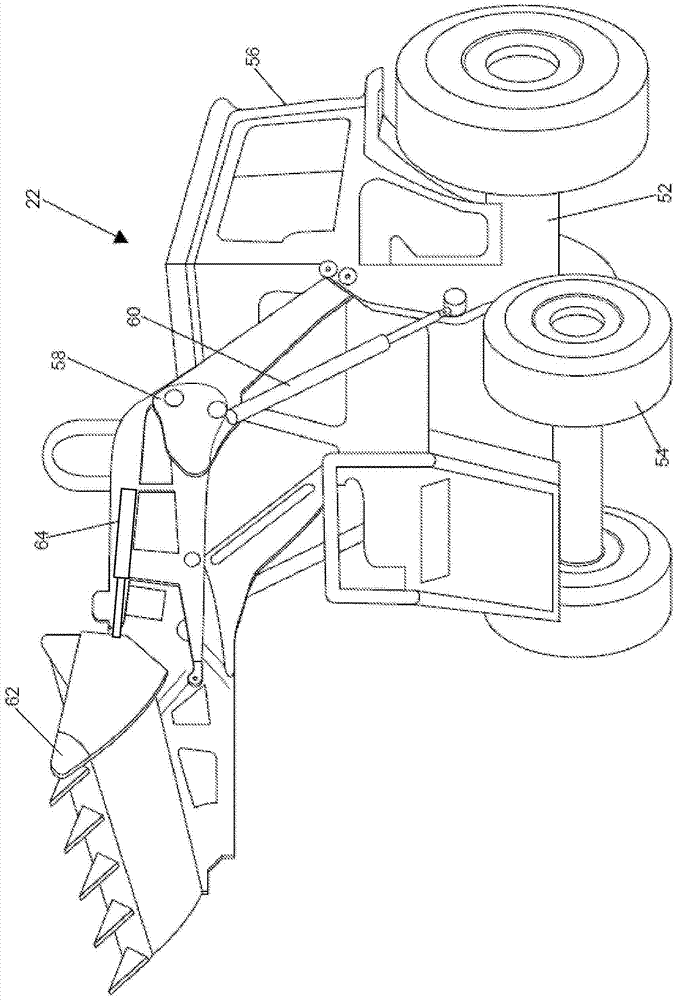

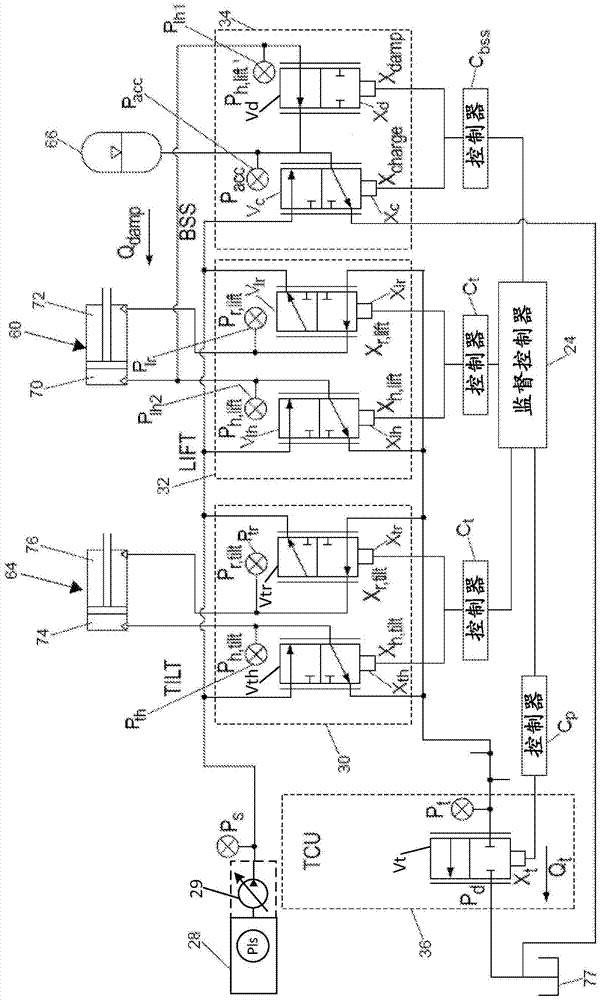

[0023] The present disclosure generally relates to fault isolation schemes for use in hydraulic actuation systems. In some embodiments, a modular and distributed control system architecture is used. By using a modular approach, the system can reduce complexity and provide increased flexibility. Enhanced fault isolation by using a distributed architecture with overlapping and redundant fault detection strategies. A controller included in the system includes a process and a non-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com