Method of beancurd skin curing and sterilization

A bean curd and curing technology, which is applied in cheese substitutes, dairy products, food preparation, etc., can solve the problems of harm and spread to human beings, and achieve the effects of easy curing, avoiding waste, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

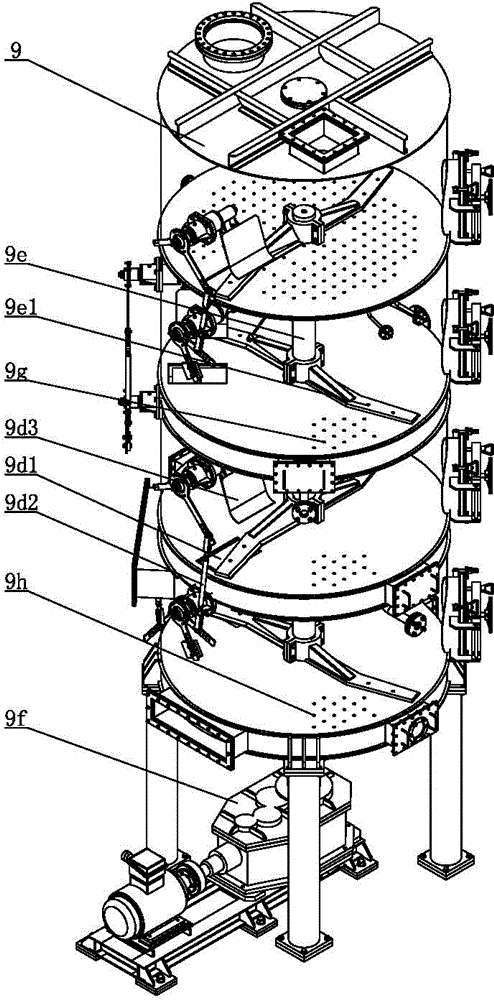

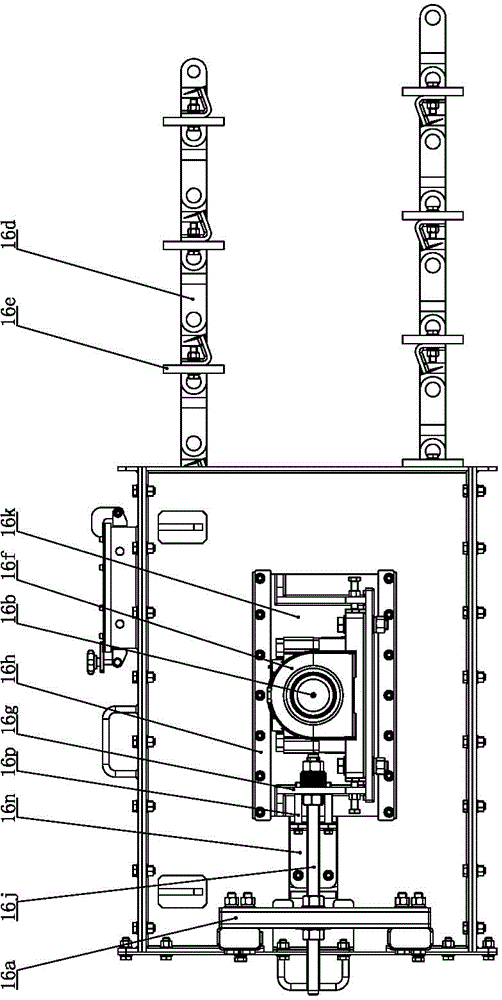

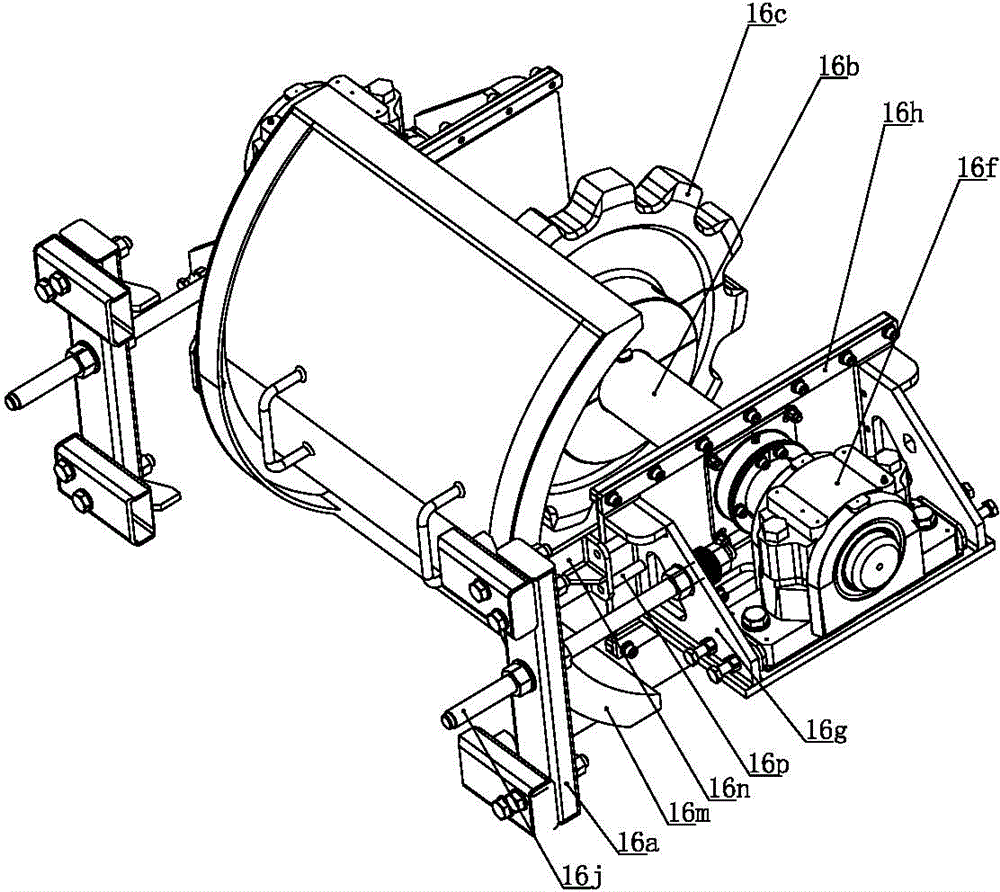

[0019] Such as figure 1As shown, the method for ripening and sterilizing bean curds of the present invention includes the following steps in turn: the bean curds separated by the soybean peeler with a bulk density of 0.08 to 0.12 t / m are sent to the hammer mill 1, and are pulverized by the hammer After being crushed by machine 1, the diameter of bean curd reaches 3.5mm or less, and the bulk density of bean curd increases to 0.15-0.35t / m3. In the case 1a; the crushed bean curd also enters the feed case 1a, and the conveying auger 4 sends the bean curd in the feed case 1a into the bucket elevator 5, and is lifted up by the bucket elevator 5 and enters the buffer storehouse 6, from After the buffer bin 6 is discharged, it is sent to the conditioner 8 by the feeding auger 7, and the saturated steam of 0.3MPa~1.0Mpa enters the conditioner 8 to perform high-temperature curing and sterilization of the bean curd, and the moisture content of the cured and sterilized bean curd is 11%~1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com