Anti-pollution and easy-to-wash hollow fiber membrane component and preparation method thereof

A fibrous membrane and easy-to-clean technology, which is applied in the field of water treatment, can solve the problems of messy, winding, and messy winding of membrane filaments, and achieve the effects of easy washing and cleaning, reduced use costs, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

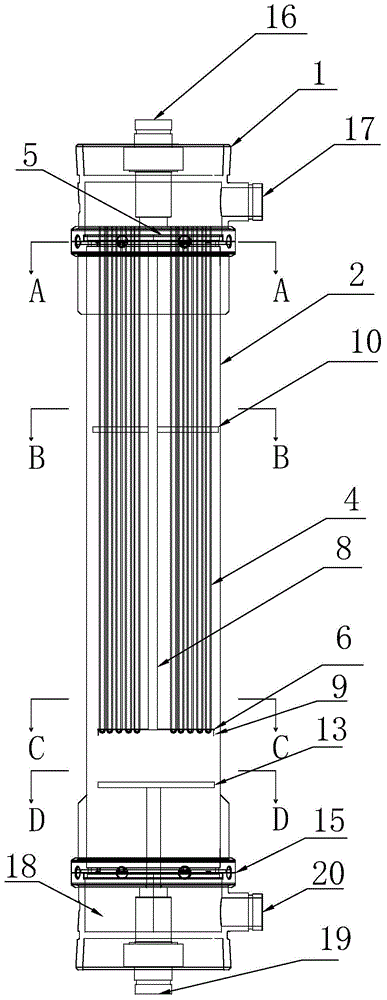

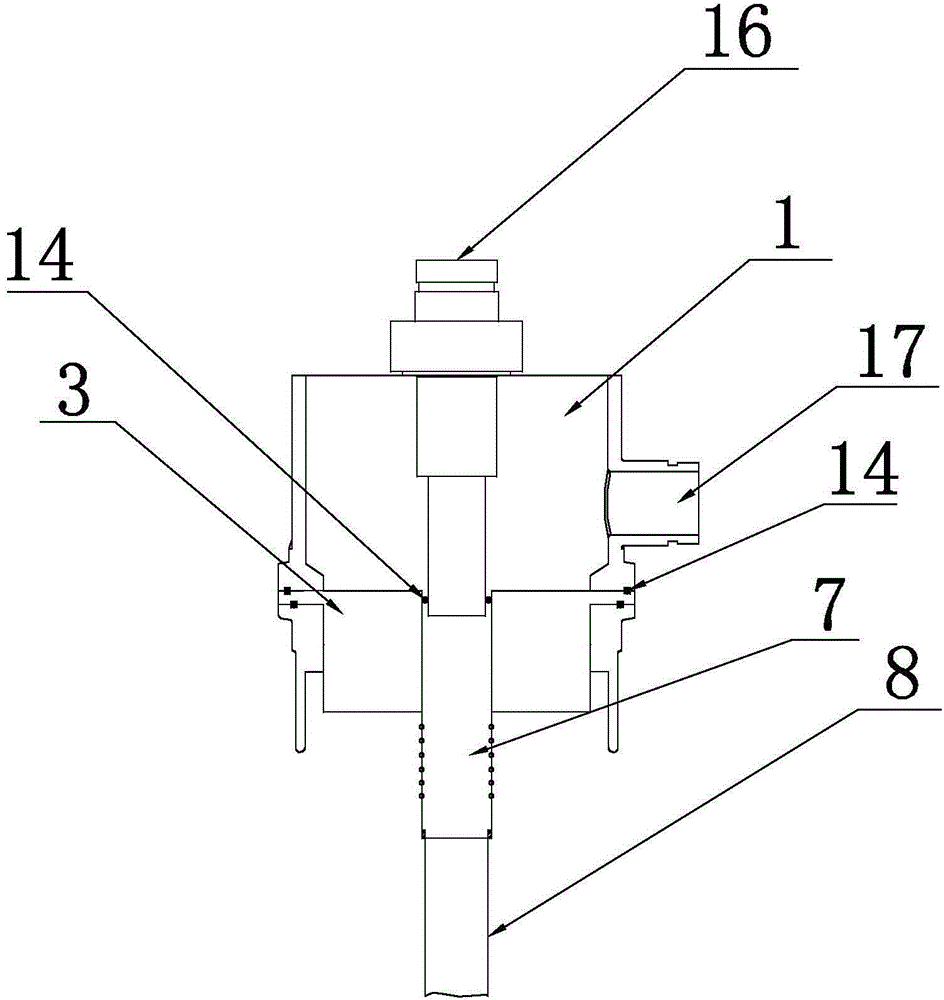

[0029] Combine below Figure 1-6 The present invention will be further described with specific embodiments.

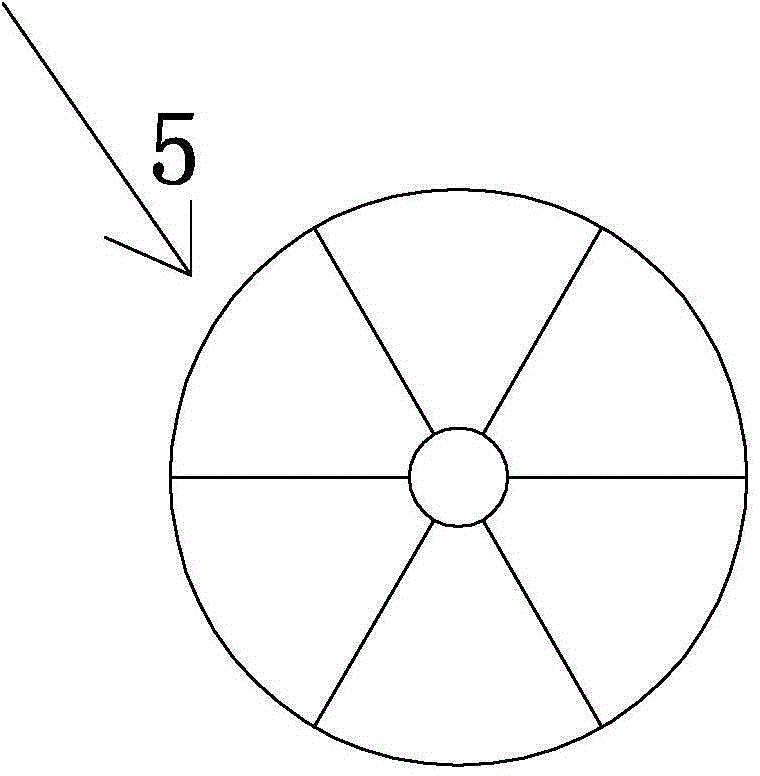

[0030] A fouling-resistant, easy-to-clean hollow fiber membrane module, such as figure 1 , 2 As shown, it includes an upper end cover 1, a housing 2, and a membrane core 3. The membrane core 3 is placed in the housing 2, the upper end cover 1 is covered on it, and the concentrated water port 16 is arranged above the upper end cover 1 along the axial direction of the housing 2. , the water production port 17 is set on the side of the upper end cover 1, the upper end cover 1 is sealed and connected with the casing 2 and the membrane core 3, the hollow fiber membrane 4 in the membrane core 3 is arranged in a U shape, the upper end cover 1, the casing 2, the membrane core 3 is detachable connection. Among them, the upper end cover 1 , the membrane core 3 and the main parts of the housing 2 are front-sealed by the O-ring 14 , and the upper end cover 1 , the membrane core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com