Method of automatic spraying on guiding blade assembly by double robots

A guide vane and automatic spraying technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the problem that the parameters such as the moving speed of the spray gun and the spraying distance vary, and the quality of the blade coating cannot be guaranteed. and other problems, to achieve the effect of good coating quality consistency, high efficiency and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

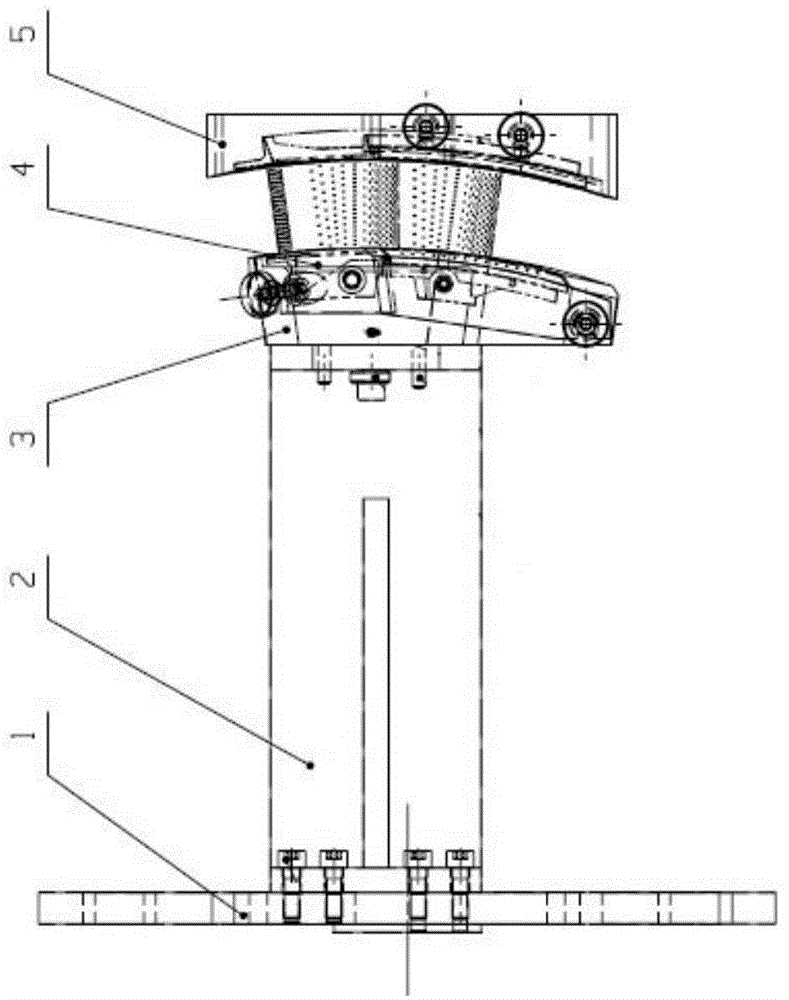

[0045] The method for automatic spraying of the guide vane assembly by dual robots proposed by the present invention comprises the following steps:

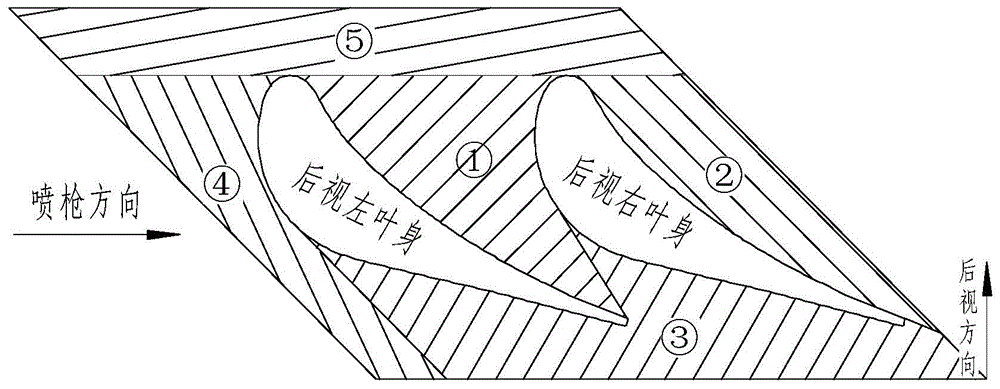

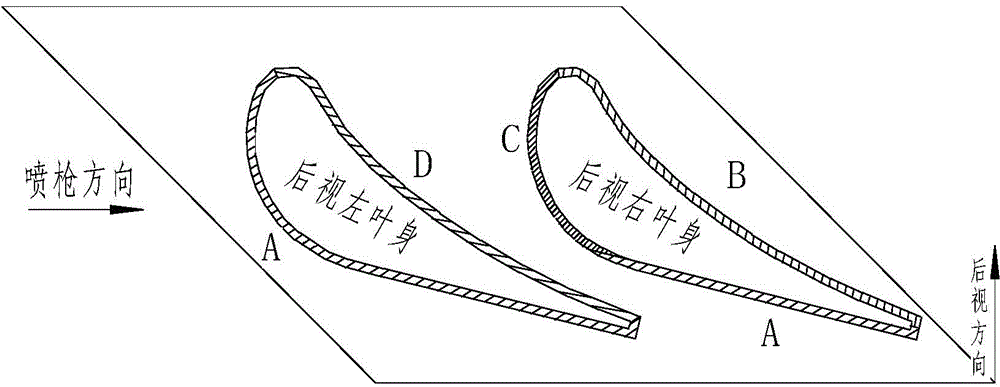

[0046] (1) See attached figure 1 with 2 , the spraying procedure of the guide vane is divided into three parts: the upper edge plate, the lower edge plate and the blade body;

[0047] See attached figure 1 , Division of the upper and lower edge plate areas: Since the upper and lower edge plate spraying areas are irregular surfaces, they are divided into five areas according to their structural characteristics and relevant requirements of the design drawing: ① The gap area between the two blade bodies, namely the rear The area surrounded by the blade basin edge of the left blade body, the blade back inlet edge of the right blade body when viewed from the back, the tangent line between the vertices of the inlet edges of the two blade bodies and the end of the blade back inlet edge of the right blade body when viewed from the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com