An automatic welding method for an intercooler and welding equipment for implementing the method

An automatic welding and cooling technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low manufacturing cost, expensive management and production, and low production technology efficiency, and achieve product quality consistency. Good, save labor cost, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

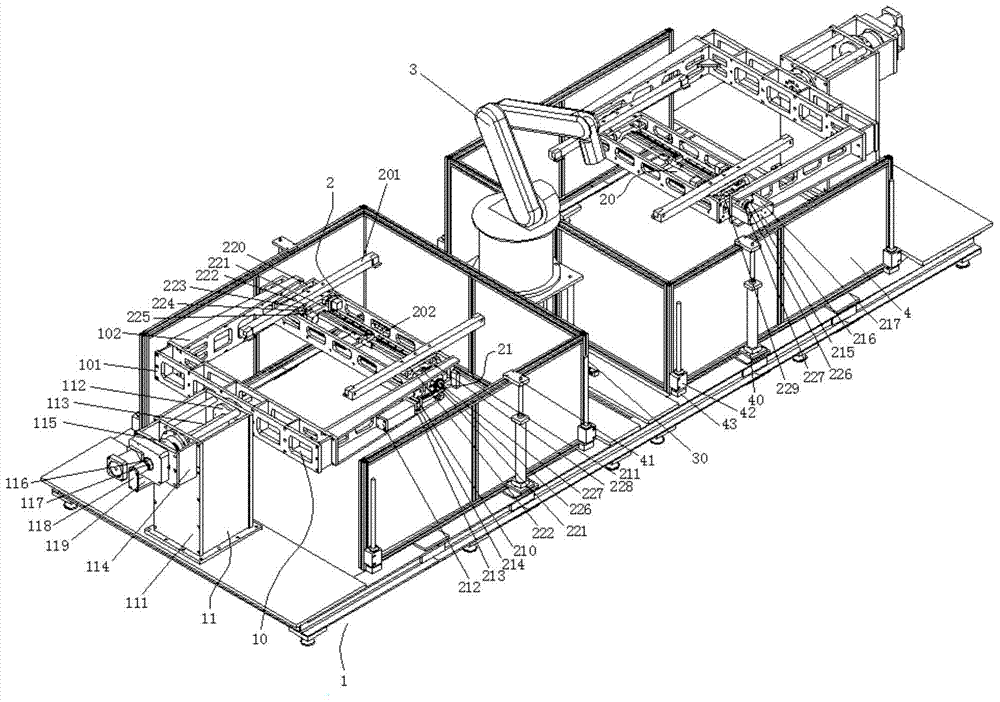

[0036] Example: see figure 1 , the intercooler automatic welding method provided by the present embodiment comprises the following steps:

[0037] (1) A welding workstation 1 is set, the workstation includes a welding support 10, and a support rotating device 11 for driving the support 10 to rotate itself to a preset angle;

[0038] (2) An intermediate turntable 2 is set, the intermediate turntable 2 is connected on the support body 10, the intermediate turntable 2 is provided with a clamping device 20 for locking and fixing the product, and is used to drive the middle turntable 2 to rotate itself to Turntable rotation device 21 with preset angle;

[0039] (3) a manipulator 3 is set, which is arranged between two welding workstations 1, and the concrete manipulator 3 includes activities on the sliding device 30, and the sliding device 30 is used to drive the manipulator 3 to do forward or backward device; on the manipulator 3 With a welding gun, the welding action is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com