Modularized downdraft type dust-removing cutting table

A cutting table, modular technology, applied in the direction of welding/cutting auxiliary equipment, workbench, auxiliary device, etc., to achieve the effect of reducing energy consumption, reducing air volume, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, single set of single side suction

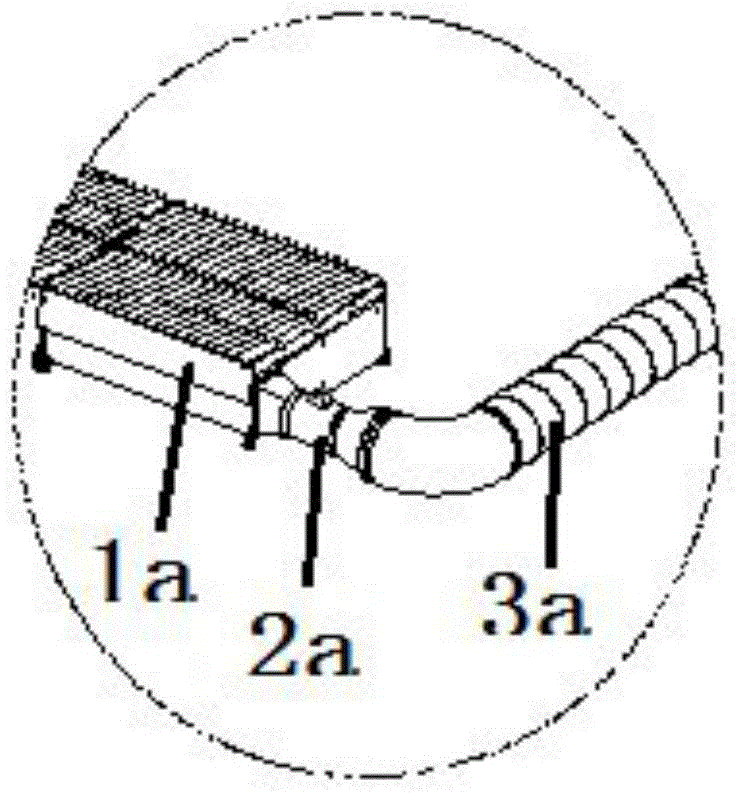

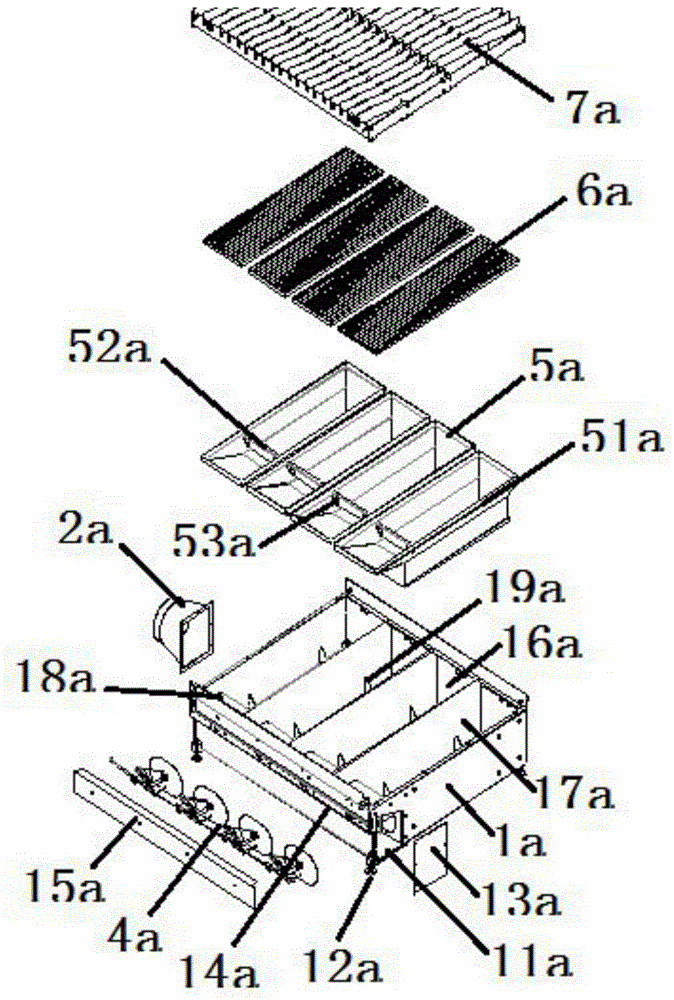

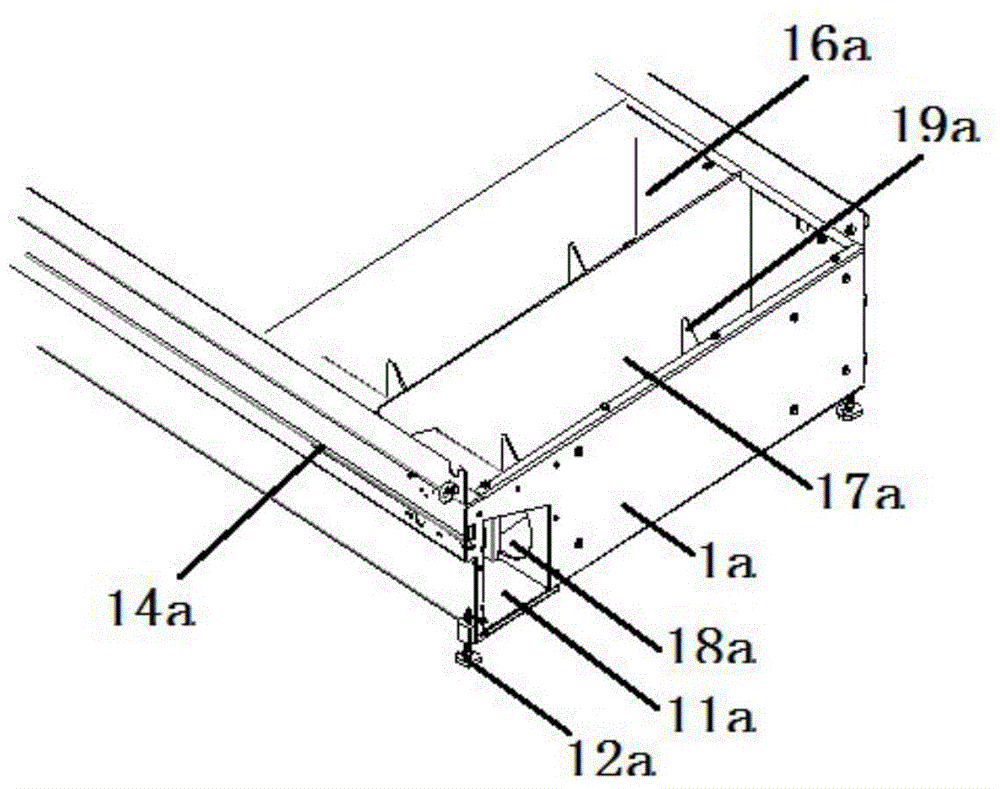

[0034] Refer to figure 1 As shown in —5, in this embodiment, the modular down-suction dust removal cutting table is composed of multiple boxes freely spliced together to form a group, and the air duct is only set on one side of the box.

[0035] A single-group single-side suction-type modular down-suction dust removal and cutting table includes at least one box body 1a on one side of which is built-in an air duct 11a that is transparent at both ends. In this embodiment, the box bodies 1a are mutually free Infinite splicing, and the air ducts 11a are all on the same side of the box body 1a, and then a group of single-group single-side suction-type dust removal cutting tables whose length can be determined according to work needs are formed. At the same time, a plurality of heavy-duty adjustable support feet 12a are provided at the bottom of each box 1a, so as to realize the load and height adjustment at the same time, so as to ...

Embodiment 2

[0045] Example 2, Multi-group single-side suction

[0046] Refer to Image 6 As shown, the only difference between this embodiment 2 and the above-mentioned embodiment 1 is that in order to meet the needs of large-area cutting, a large number of the boxes 1a are freely and infinitely spliced to form multiple groups of modular downward suction dust removal cutting tables, and each group has The air ducts 11a are all on the same side, and the air ducts 11a in each group are connected to the same dust suction pipe 3a through the adapter 2a. The other components and structures in this embodiment are not changed, therefore, the relevant description can be seen in the above embodiment 1.

Embodiment 3

[0047] Example 3, single set of bilateral suction

[0048] See Figure 7 As shown in —11, in this embodiment, the modular down-suction dust removal cutting table is composed of a set of freely spliced boxes, and there are air ducts on both sides of the box.

[0049] A single set of bilateral suction type modular down-suction dust removal and cutting table includes at least one box body 1b with built-in air ducts 11b at both sides of which are transparent at both ends. In this embodiment, the boxes 1b can be free from each other Infinite splicing, and the air ducts 11b are all on the same side, so as to form a single set of bilateral suction-type dust removal cutting tables whose length can be determined according to work requirements. At the same time, a plurality of heavy-duty adjustable support feet 12b are provided at the bottom of each box 1b, so as to realize the load and height adjustment at the same time to meet the requirements of the working conditions;

[0050] A single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com