Rear installation structure of motorcycle fuel tank

An installation structure and technology for motorcycles, which can be used in gasoline barrels, bicycle accessories, transportation and packaging, etc. It can solve the problems of complex welding process of fuel tanks, affecting riding comfort, numbness of driver's legs, etc., so as to achieve firm connection and Reliable, improve the shock absorption effect and riding comfort, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

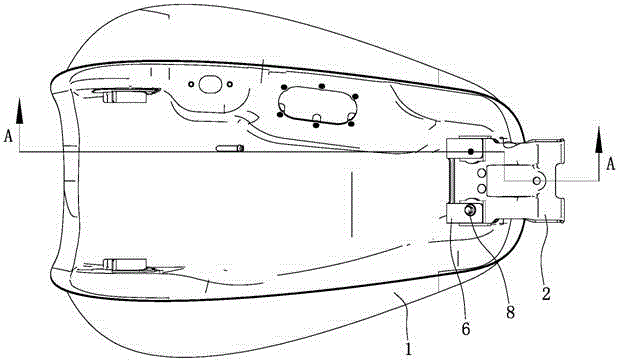

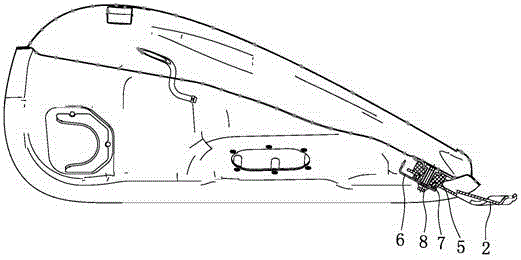

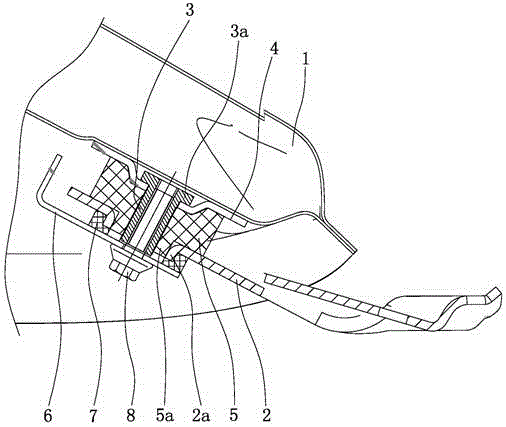

[0014] like figure 1 , figure 2 , image 3 As shown, the present invention is made of fuel tank 1, rear mounting bracket 2, screw sleeve 3, positioning plate 4, first shock absorber 5, pressing plate 6, second shock absorber 7 and screw 8 etc. Wherein, two screw sleeves 3 are welded side by side at the bottom of the tail end of the fuel tank 1. The screw sleeves 3 are arranged with a low front and a high rear. Set the positioning plate 4 and the first shock pad 5 on the screw sleeve 3, the positioning plate 4 is located above the first shock pad 5, and the corresponding screw sleeve 3 places on the positioning plate 4 are formed with sinking grooves through depressions, and the upper end of the screw sleeve 3 The head boss 3a is located in the sinker.

[0015] like figure 1 , figure 2 , image 3 As shown, the first shock absorbing pad 5 presses the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com