Anti-corrosion oxidant for refractory materials and preparation method thereof

A refractory material and anti-corrosion technology, which is applied in the field of anti-corrosion oxidant for refractory materials and its preparation, can solve the problems of insufficient anti-corrosion performance and high cost of using antioxidants, achieve good anti-oxidation performance, improve anti-corrosion performance, and good resistance force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

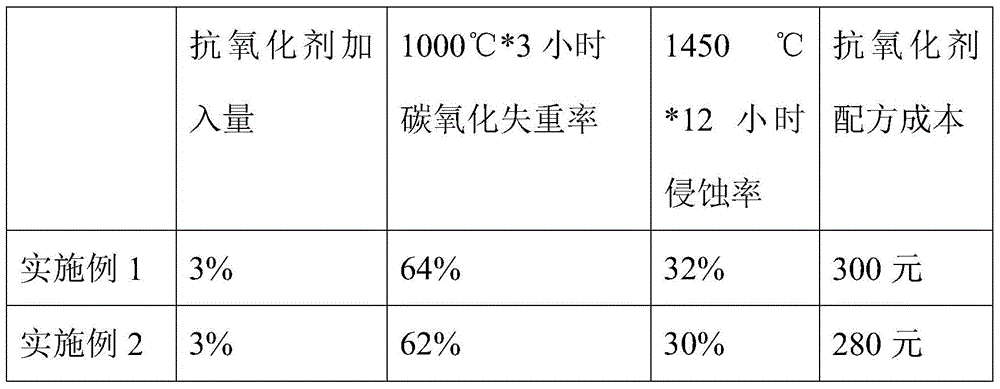

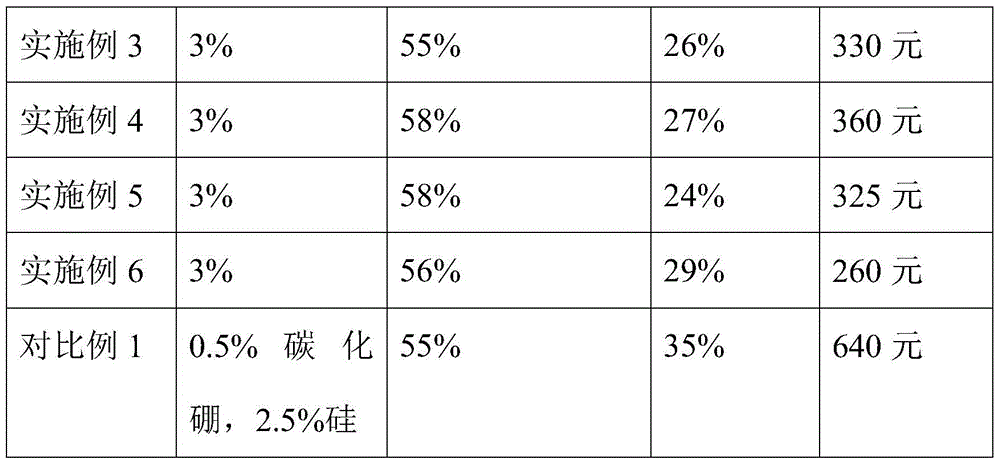

Examples

Embodiment 1

[0023] Embodiment 1: An anti-corrosion oxidant for refractory materials, which is prepared by mixing the following raw materials according to mass percentage: 80% of silicon carbide micropowder, 10% of alumina micropowder, 8% of borate, and 2% of sodium polyacrylate.

[0024] In the above solution, the silicon carbide micropowder is high-purity silicon carbide, its silicon carbide content is ≥ 97%, and its median particle size is 3 microns.

[0025] In the above solution, the alumina micropowder is calcined α-alumina, with a median particle size of 1 micron.

[0026] In the above scheme, the borate is ammonium borate and zinc borate, wherein ammonium borate is 5% and zinc borate is 3%.

[0027] In the above scheme, the molecular weight of the sodium polyacrylate is 1000.

[0028] The preparation method of the present invention comprises the steps of:

[0029] (1) Grinding the silicon carbide micropowder, alumina micropowder, borate, and sodium polyacrylate through a ball mil...

Embodiment 2

[0031] Embodiment 2: An anti-corrosion oxidant for refractory materials is prepared by mixing the following raw materials according to mass percentage: 85% of silicon carbide micropowder, 7% of alumina micropowder, 3% of borate, and 5% of sodium polyacrylate.

[0032] In the above solution, the silicon carbide micropowder is high-purity silicon carbide, its silicon carbide content is ≥ 97%, and its median particle size is 5 microns.

[0033] In the above solution, the alumina micropowder is calcined α-alumina with a median particle size of 5 microns.

[0034] In the above scheme, the borate is ammonium borate, wherein the mass fraction of ammonium borate is 3%.

[0035] In the above scheme, the molecular weight of the sodium polyacrylate is 2000.

[0036] The preparation method of the present invention comprises the steps of:

[0037] (1) Grinding silicon carbide micropowder, alumina micropowder, borate and sodium polyacrylate through a ball mill for 20 minutes, adding water...

Embodiment 3

[0039] Embodiment 3: An anti-corrosion oxidant for refractory materials, which is prepared by mixing the following raw materials according to mass percentage: 90% of silicon carbide micropowder, 5% of alumina micropowder, 4% of borate, and 1% of sodium polyacrylate.

[0040] In the above solution, the silicon carbide micropowder is high-purity silicon carbide, its silicon carbide content is ≥ 97%, and its median particle size is 3 microns.

[0041] In the above solution, the alumina micropowder is calcined α-alumina with a median particle size of 3 microns.

[0042] In the above scheme, the borate is ammonium borate, wherein the mass fraction of ammonium borate is 4%.

[0043] In the above scheme, the molecular weight of the sodium polyacrylate is 1500.

[0044] The preparation method of the present invention comprises the steps of:

[0045] (1) Grinding the silicon carbide micropowder, alumina micropowder, borate, and sodium polyacrylate through a ball mill for 20 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com