Lubricant and preparation method thereof

A technology of lubricant and defoaming agent, applied in the field of lubricant and preparation, can solve the problems of viscosity of drilling fluid, increase of shear force, influence on oil and gas formation of logging staff, influence on well slurry performance, etc., and achieve low foaming performance. , Well slurry performance has no adverse effect, the effect of low fluorescence level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

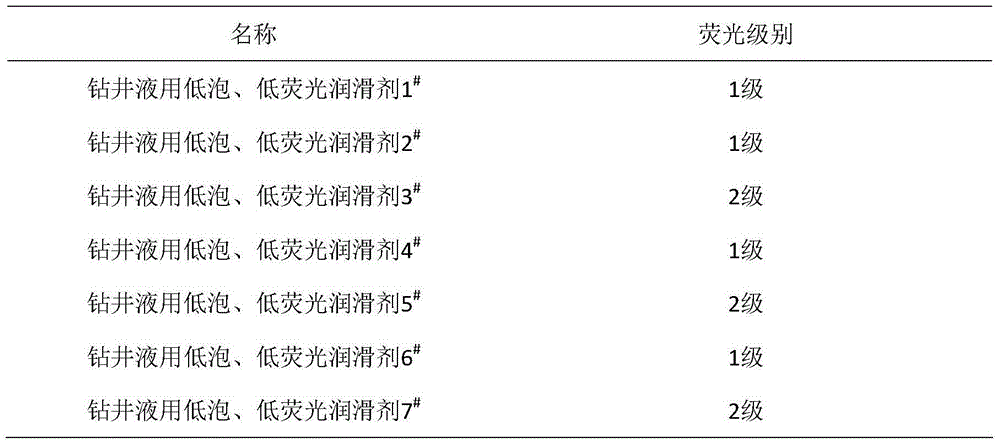

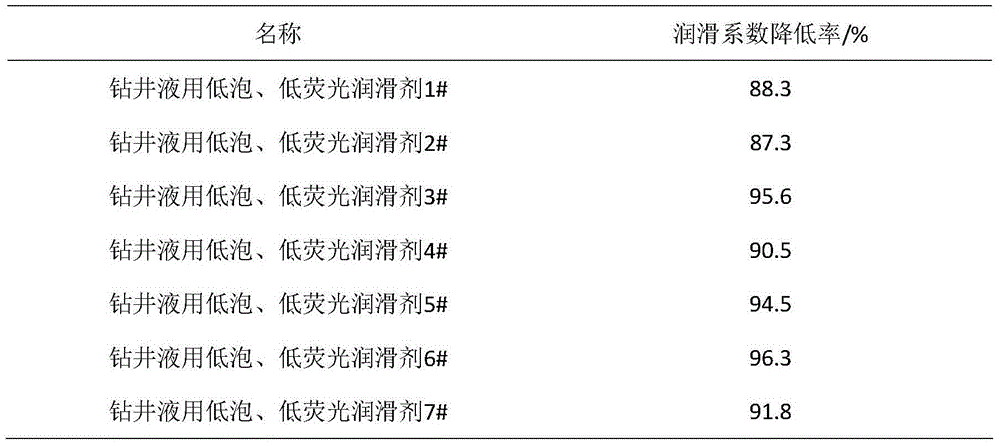

Embodiment 1

[0018] Add 25 parts of 150SN and 60 parts of glycerin fatty acid ester into the reaction kettle, raise the temperature to 50°C, stir at high speed for 0.5h, slowly add 10 parts of Span-80, stir at high speed for 0.5h, raise the temperature to 70°C, slowly add 5 parts The antifoaming agent silicone continued to stir for 0.5h, and cooled to obtain a low-foaming and low-fluorescence lubricant for drilling fluid 1 # .

Embodiment 2

[0020] Add 30 parts of 150SN and 56 parts of propylene glycol monooleate into the reaction kettle, raise the temperature to 80°C, stir at high speed for 0.5h, slowly add 8 parts of Tween-80, stir at high speed for 0.5h, raise the temperature to 100°C, slowly add 6 part of antifoaming agent modified silicone and continue to stir for 0.5h, and cool down to obtain low-foaming and low-fluorescence lubricant for drilling fluid 2 # .

Embodiment 3

[0022] Add 30 parts of 60SN and 56 parts of propylene glycol monooleate into the reaction kettle, raise the temperature to 70°C, stir at high speed for 0.5h, slowly add 8 parts of MOA-4, stir at high speed for 0.5h, raise the temperature to 90°C, slowly add 6 part of antifoaming agent glycerol polyether and continue to stir for 0.5h, then cool to obtain low-foaming and low-fluorescence lubricant for drilling fluid 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com