Patents

Literature

42results about How to "Prevent re-formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toothpaste containing persimmon leaf extracts

InactiveCN104257547AEfficient removalPrevent re-formationCosmetic preparationsToilet preparationsSpecial effectsNutritional composition

The invention discloses toothpaste containing persimmon leaf extracts, and relates to the technical field of oral care products. The toothpaste is prepared from the following compositions in percentage by mass: 2-7 percent of persimmon leaf extract gingival-protecting whitening toothpaste and 3-8 percent of persimmon leaf extract comprehensive special effect tartar toothpaste; the persimmon leaf extract comprehensive special effect dental calculus toothpaste is prepared from the following compositions in percentage by mass: 2 percent of persimmon leaf extracts, 0.1 percent of saccharin sodium salt, 0.5 percent of newtol, 0.2 percent of sodium benzoate, 0.3 percent of baking soda, 60 percent of sorbitol, 2 percent of PEG400, 18 percent of silicon dioxide, 0.2 percent of titanium dioxide, 1 percent of carboxymethylcellulose, 2.2 percent of dodecyl sulfuric acid, 1.3 percent of essence, 0.5 percent of sodium phytic acid, and the balance of deionized water. A preparation method of the toothpaste containing persimmon leaf extracts is simple; the regeneration of dental calculus can be prevented while dental calculus which is accumulated for many years can be effectively removed at the same time; because of nutritional ingredients contained in the toothpaste, the gingival can be rapidly grown, the tooth health can be effectively protected, and the compositions are pure natural and have no toxic and side effects.

Owner:张建瑞

Medicine for treating kidney stone and gall-stone

InactiveCN102743586AGuaranteed Active IngredientsImprove efficacyOrganic active ingredientsAnthropod material medical ingredientsKidney stoneExcretion

The invention discloses a medicine for treating kidney stone and gall-stone, according to a calculus formation pathology and a pharmacological experiment formula, the medicine of the invention is prepared by arbutin, desmodium, lichee nucleus, longan nucleus, common fenugreek seed, gecko, pig iron cinder, gynostemma pentaphylla, plantago, Orthosiphon Stamineus, Caulis aristolochiae manshuriensis, bletilla rhizome, magnolia cortex and sweetleaf tea. The materials are natural-green, safe and reliable. A traditional Chinese medicine toxin expelling therapy is used. The medicine is capable of releasing spasm, relieving pain, smoothing skin, sterilizing, softening hardness and dissipating binds, soothing liver and resolving depression, clearing heat and dispersing stagnate, rectifying qi, disinhibiting urine and freeing strangury and benifiting openheartedness, the medicine can directly act on nidus, an organic matter is subjected to releasing, dissolving and biological enzymatic hydrolysis, can comprehensively permeated in a core of the calculus, the calculus can be cracked, melted and dissolved layer by layer from outer part to inner part, and the waste liquid is excreted through human excretion tissue, and the damaged cells can be activated, the gland can be balanced, the organ vitality can be enhanced, the acid-base value of blood can be balanced, the calculus recurrence can be prevented, and the simultaneous treatment of principal and subordinate symptoms effect can be acted.

Owner:王启凌

Environment-friendly cleaning agent for mechanical equipment

InactiveCN103436394APrevents rust from recurringShorten cleaning timeSurface-active non-soap compounds and soap mixture detergentsChemistryWater soluble

The invention discloses an environment-friendly cleaning agent for mechanical equipment. The environment-friendly cleaning agent comprises the following substances in parts by weight: 25-32 parts of triethanolamine, 1-5 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 3-8 parts of a degreasing agent, 7-12 parts of degreasing powder, 11-15 parts of a surface regulating agent, 8-10 parts of potassium sulfate, 10-16 parts of anhydrous sodium sulfate, 5-16 parts of potassium nitrate, 7-15 parts of sodium nitrite, 2-4 parts of sodium sulfite, 1-3 parts of dispersant, 1-3 parts of thickener, 4-6 parts of flame retardant, 4-8 parts of stearic acid, 7-14 parts of stearate, 4-15 parts of stearamide, 1-3 parts of silicone oil and 4-10 parts of oleamide. The environment-friendly cleaning agent has an efficient and easy cleaning effect on the mechanical equipment, so that oil stains and rusty spots on the surface of the mechanical equipment are thoroughly cleaned, the surface of the mechanical equipment can be prevented from forming the rusty spots again, the time for cleaning can be shortened, and the work efficiency is increased; the environment-friendly cleaning agent is a water-soluble cleaning agent and has low corrosiveness on the equipment, so that the production cost is reduced effectively, and the use is safe and reliable.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Biodegradable magnesium alloy bile duct stone-dissolving carving stent and preparation method thereof

InactiveCN102727948APrevent closureGuaranteed unobstructedStentsSurgeryBile ducts stonesDisodium Edetate

The invention, belonging to the field of biomedicine, bio-polymer material and magnesium alloy material, relates to a biodegradable magnesium alloy bile duct stone-dissolving carving stent and a preparation method thereof. The stent is prepared by processing magnesium or magnesium alloy into hollow tubes, carving the hollow tubes under the action of laser to a tubular stent with a porous reticular or spiral tubular structure, and then coating a biodegradable polymer layer containing sodium cholate or / and edetate disodium on the inner surface and outer surface of the tubular stent. Clinical outcomes show that the stone-dissolving bile duct stent of the invention has good radial supporting performance, can keep the bile duct open, can be degraded away in a certain time with no need of removing the stent, has good biocompatibility, and lets almost no internal inflammation generate. Simultaneously, sodium cholate or / and edetate disodium slowly released by the polymer layer containing drugs can dissolve the formed stones and can prevent the re-formation of stones.

Owner:SHANGHAI FIRST PEOPLES HOSPITAL

Two-section gas nitridation method for surfaces of aluminum and aluminum alloy

InactiveCN102925851AEliminate dense oxide filmStrong penetrating powerSolid state diffusion coatingSurface oxidationPre treatment

The invention relates to a two-section gas nitridation method for the surfaces of aluminum and aluminum alloy. The method comprises a surface oxidation film removing step and a surface nitridation treatment step. The step 1 comprises the following steps of: pre-treating; primarily galvanizing zinc; washing by water; removing zinc; secondarily galvanizing zinc; and drying after water washing. The step 2 comprises the following steps of: exhausting in a furnace, wherein the ammonia resolution ratio is less than 10%; primarily heating to 570-590 DEG C, wherein the ammonia resolution ratio is 15-25%; carrying out one-section nitridation, wherein the furnace temperature is 580-640DEG C, and the ammonia resolution ratio is kept at 15-25%; secondarily heating to 620-640 DEG C, wherein the ammonia resolution ratio is 40-55%; carrying out two-section nitridation, wherein the temperature is 620-640DEG C, and the ammonia resolution ratio is 40-55%; and denitriding, wherein the furnace temperature is 580-640DEG C, and the ammonia resolution ratio is controlled at 70-80%. The two-section gas nitridation method has the advantages that compact oxidation films on the surfaces of aluminum and the aluminum alloy can be effectively eliminated, the nitrogen atom can be preferably infiltrated, the nitridation treatment can be carried out by a common gas nitridation furnace, and the two-section gas nitridation method is low in production cost, simple and easy to operate, wide in adaptability, and good in infiltration layer quality.

Owner:JIANGSU UNIV

Surface three-step nitridation method of aluminium and aluminium alloy

InactiveCN102943231AEfficient removalStrong penetrating powerSolid state diffusion coatingFurnace temperatureSurface oxidation

The invention relates to a surface three-step nitridation method of aluminium and aluminium alloy, comprising the following steps: 1, removing surface oxide-films; 2, conducting surface nitridation treatment, wherein the step 1 successively comprises: pretreating, conducting a first zinc immersion, washing, removing zinc, conducting a secondary zinc immersion, and washing and drying; and the step 2 successively comprises: discharging oxygen, heating up to let the furnace temperature be 300 DEG C, and controlling the ammonia dissociation rate below 10%; heating up to 560-590 DEG C for the first time; nitriding for the first time at the furnace temperature of 560-590 DEG C; heating up to 620-640 DEG C for the second time; conducting secondary nitriding at the furnace temperature of 620-640 DEG C; cooling to let the furnace temperature be 570-600 DEG C; nitriding for the third times at the furnace temperature of 570-600 DEG C; and denitriding at the furnace temperature of 570-600 DEG C. According to the invention, the surface dense oxide-films of aluminium and aluminium alloy can be effectively removed, the infiltration of nitrogen atoms is benefited, and nitridation treatment can be conducted by using a common gas nitriding furnace, thus the production cost is low, the operation is simple, the adaptability is wide, and the infiltrated layer has good quality.

Owner:JIANGSU UNIV

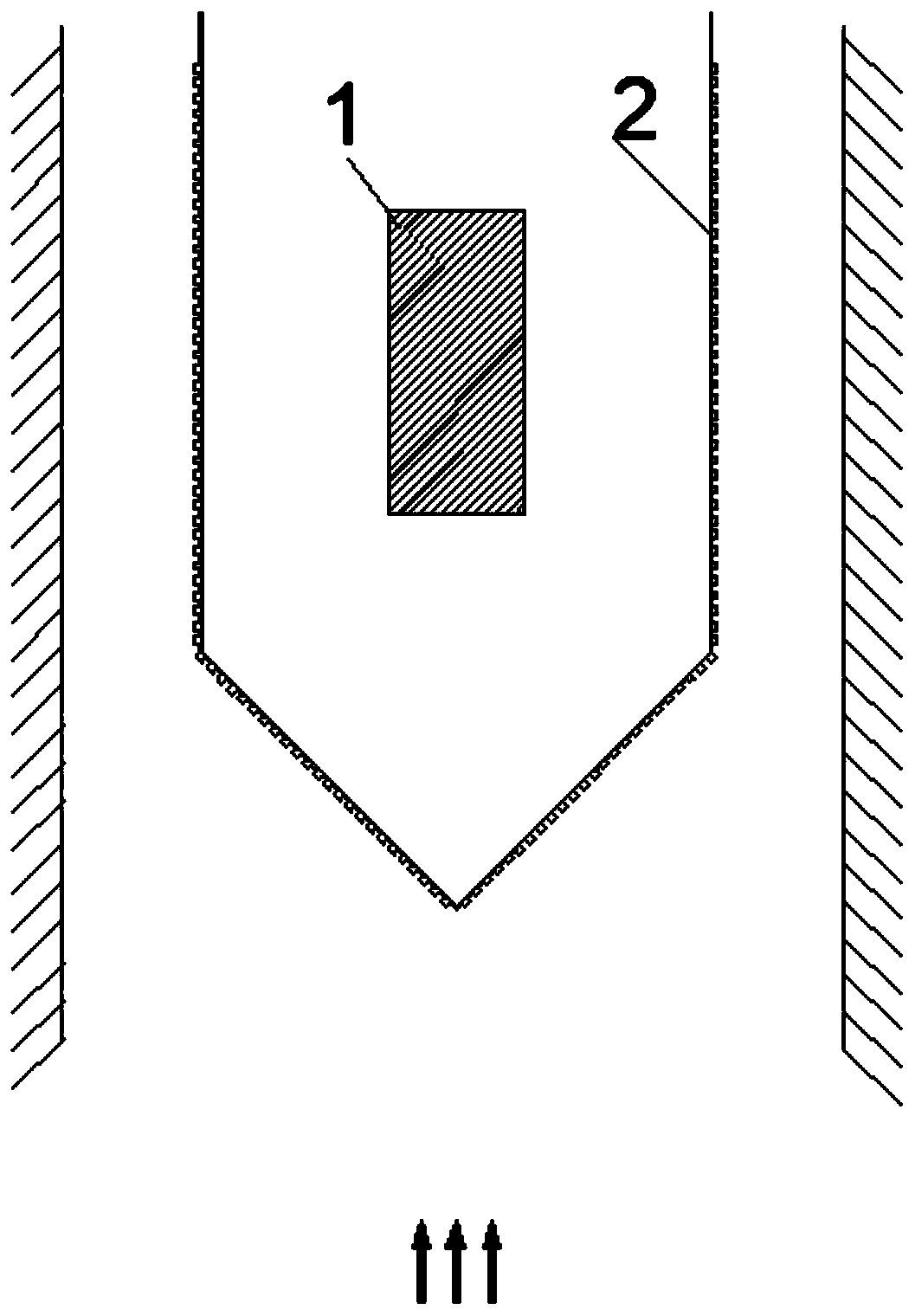

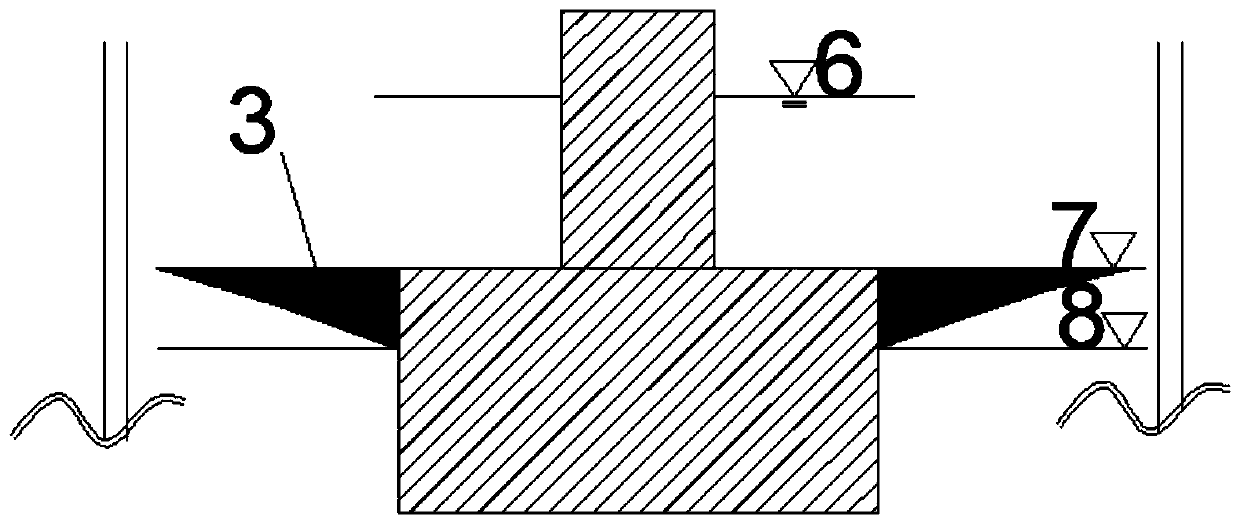

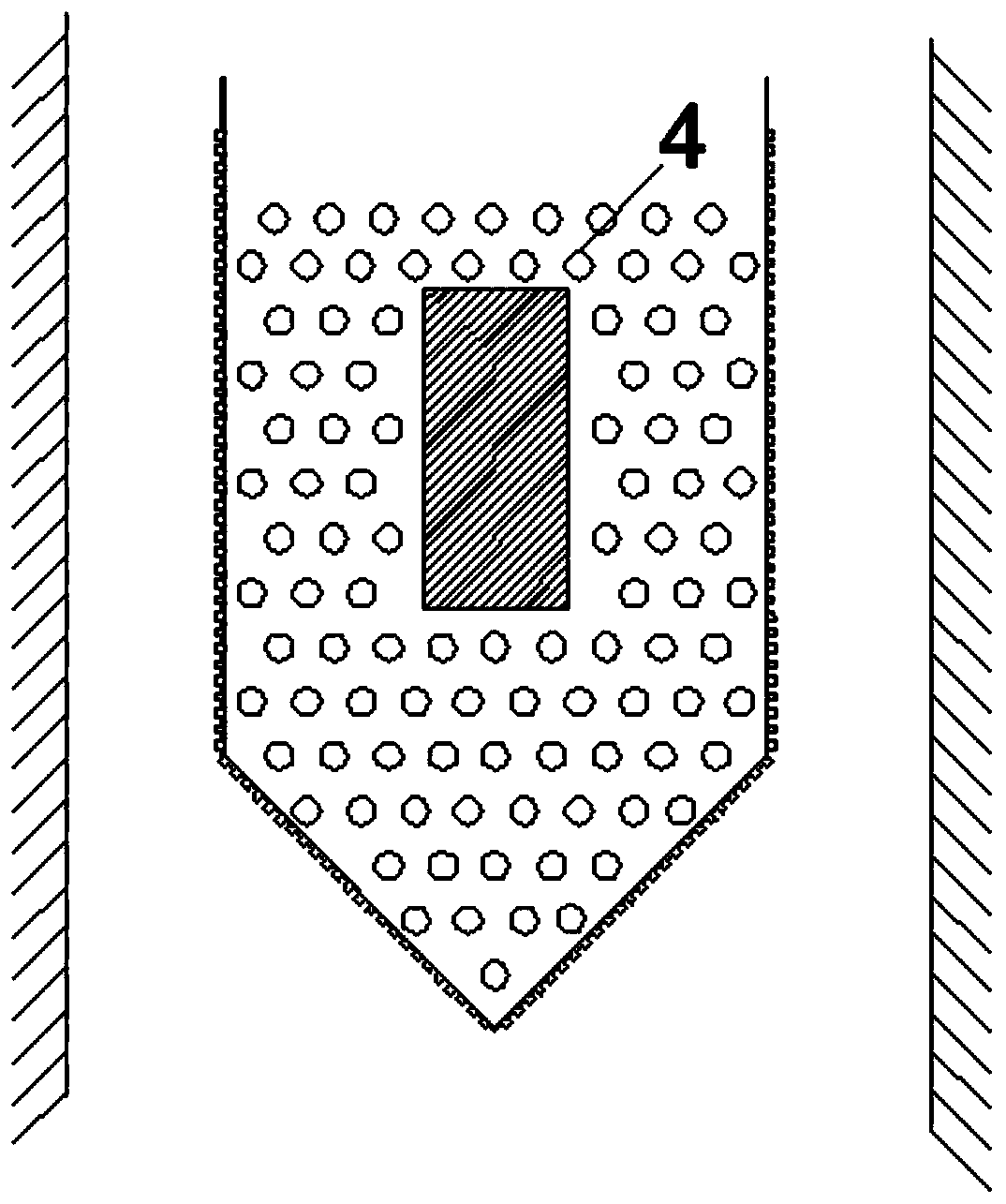

Bridge pier flow goaf reinforcing method

InactiveCN110485313AGood water blocking effectReduce dosageBridge erection/assemblyBridge strengtheningWater flowHigh pressure

The invention discloses a bridge pier flow goaf reinforcing method which comprises the following steps of 1), determining the range of a pier flow goaf, and driving the continuous steel sheet piles toenclose the flow goaf; 2) determining the scouring depth, and backfilling the sandy soil in the flow goaf to restore the flow goaf to be slightly higher than an original riverbed; 3) driving a vibroflotation high-pressure grouting pile group in the flow gob area; and 4) pulling out the steel sheet piles. According to the method, the reinforcing range of the pier to be reinforced is determined, the steel sheet piles are driven in the to-be-reinforced area to block the water flow, and then the sandy soil is backfilled, then the vibroflotation high-pressure grouting piles are driven into the reinforcing area for solidifying the soil body in the flow goaf. The pile body of the pile can form a composite foundation with a soil body, so that the backfill soil has the higher flow scouring resistance, the regeneration of the flow goaf is effectively avoided, the overall strength of the soil foundation of the the flow goaf is greatly improved, the water flow characteristic can be affected afterthe grouting piles are solidified, the scouring effect of the water flow on the pier can be reduced, and the bearing capacity and the flood-resisting scouring resistance of the pier are greatly improved.

Owner:OCEAN UNIV OF CHINA

Perilla fruit blended edible vegetable oil enriched in essential fatty acids and vitamin F

InactiveCN102113575AInhibit synthesisInhibition of re-formationEdible oils/fatsVegetable oilPerilla oil

The invention relates to perilla fruit blended edible vegetable oil enriched in essential fatty acids and vitamin F, which belongs to the technical field of food production. The perilla fruit blended edible vegetable oil is prepared by blending perilla oil, evening primrose oil and cameline oil, and can be directly consumed or used as edible oil for frying dishes and making soup or cold vegetable dishes in sauce. The perilla fruit blended edible vegetable oil provided by the invention can be used for effectively preventing and treating cardiovascular and cerebrovascular diseases and hypertension, with no relapse after healing; and the lives of people can be effectively prolonged.

Owner:高英林 +1

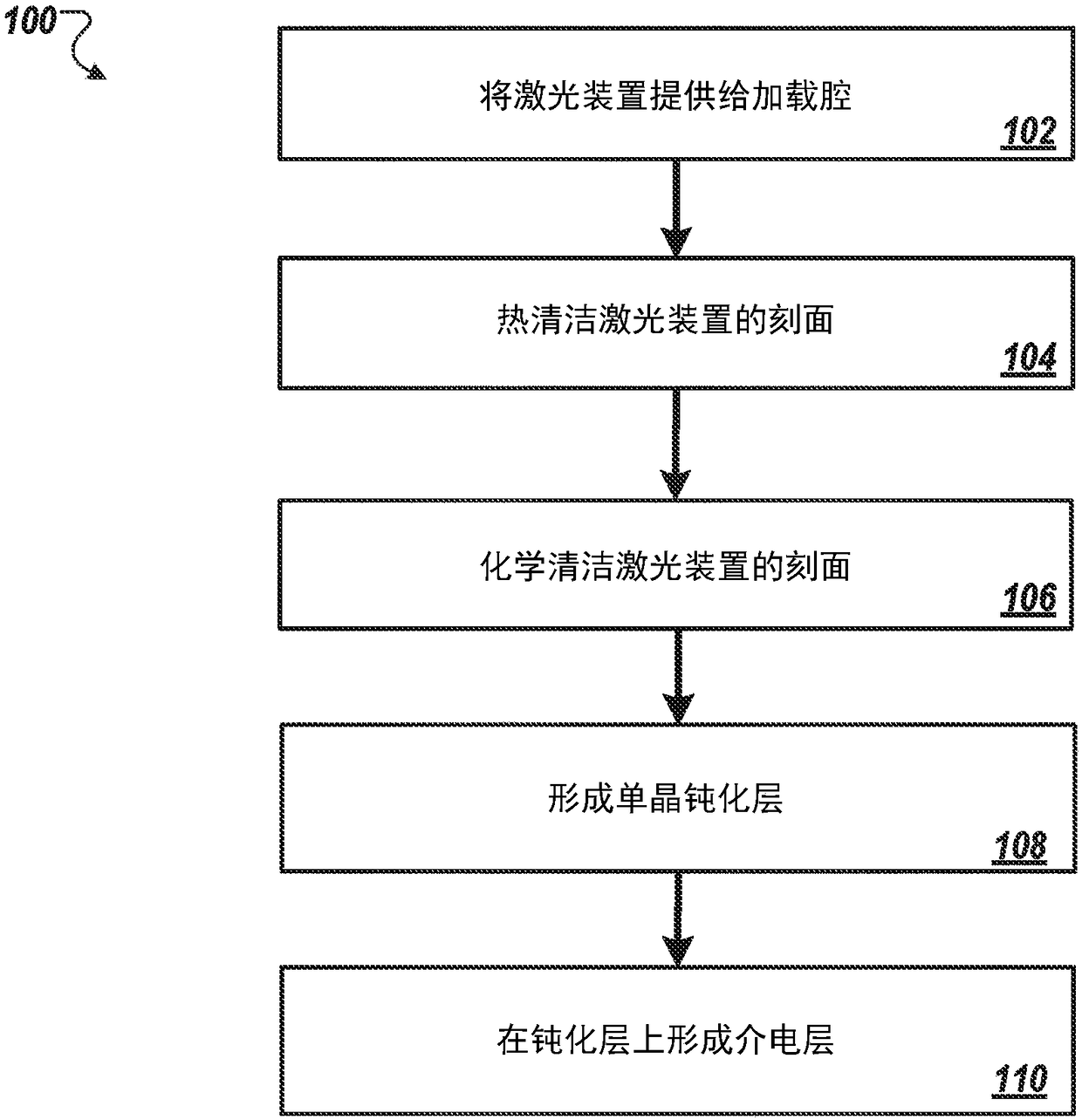

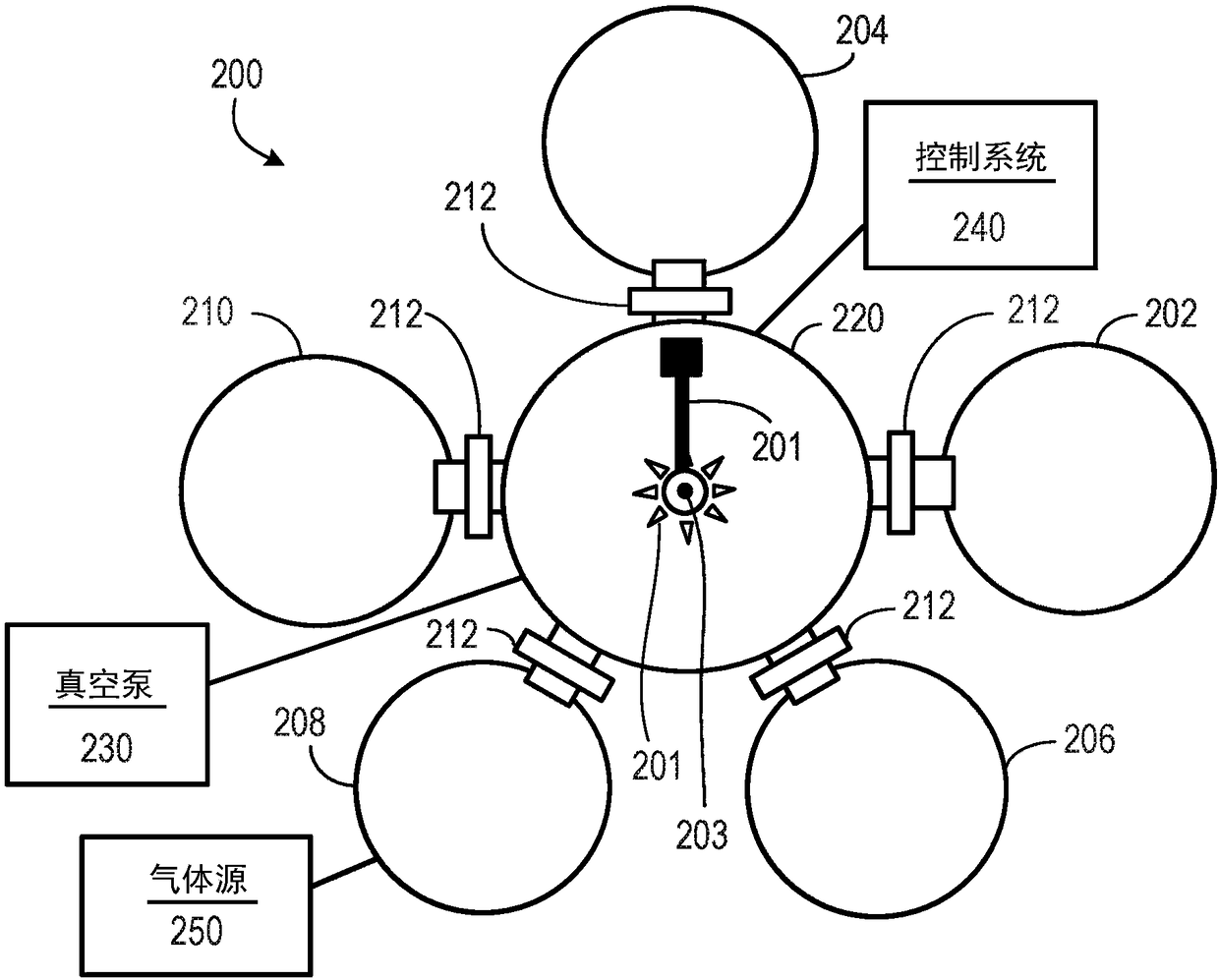

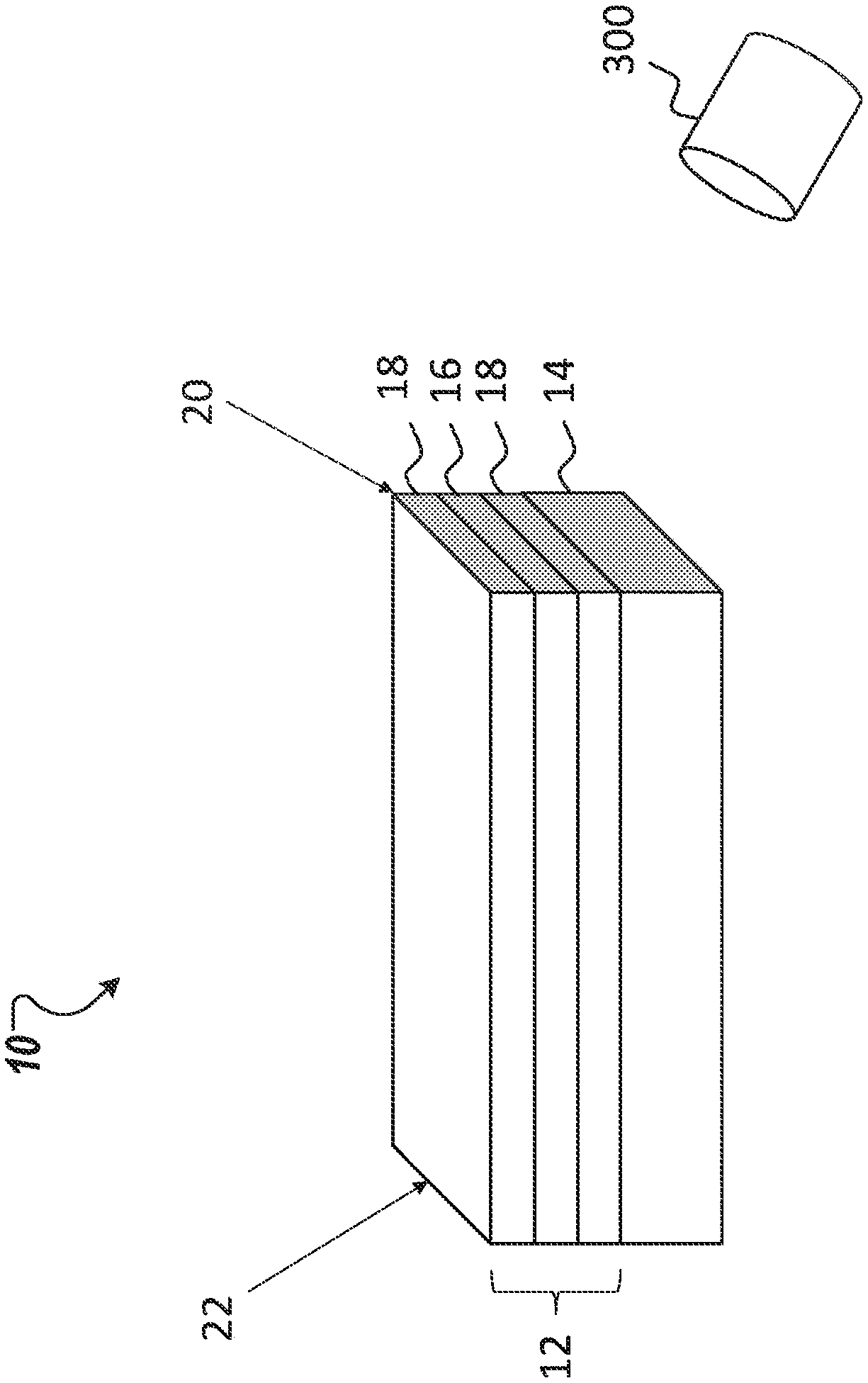

Passivation of laser facets and systems for performing the same

ActiveCN109478765ALow reliabilitySolution to short lifePolycrystalline material growthLaser detailsUltra-high vacuumSingle crystal

Methods of passivating at least one facet of a multilayer waveguide structure can include: cleaning, in a first chamber of a multi-chamber ultra-high vacuum (UHV) system, a first facet of the multilayer waveguide structure; transferring the cleaned multilayer waveguide structure from the first chamber to a second chamber of the multi- chamber UHV system; forming, in the second chamber, a first single crystalline passivation layer on the first facet; transferring the multilayer waveguide structure from the second chamber to a third chamber of the multi-chamber UHV system; and forming, in the third chamber, a first dielectric coating on the first single crystalline passivation layer, in which the methods are performed in an UHV environment of the multi-chamber UHV system without removing themultilayer waveguide structure from the UHV environment.

Owner:TRUMP PHOTONICS

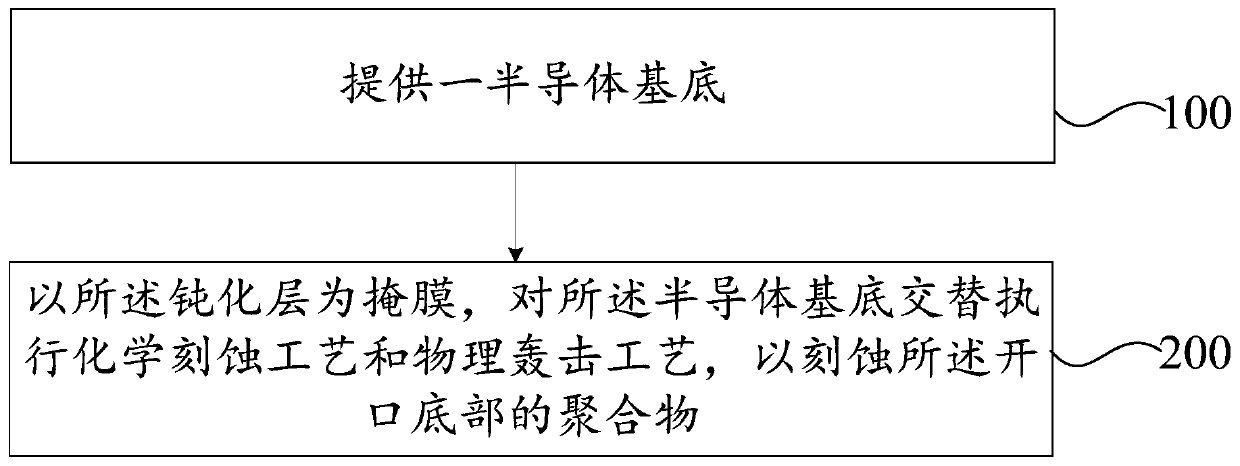

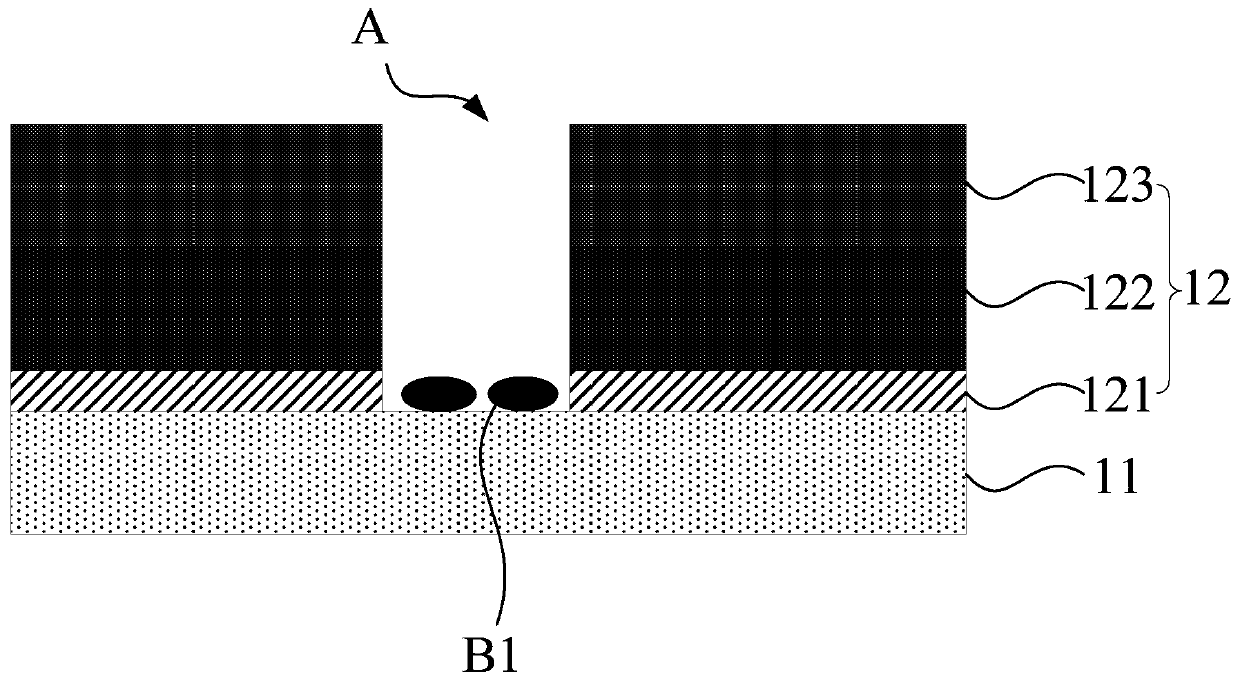

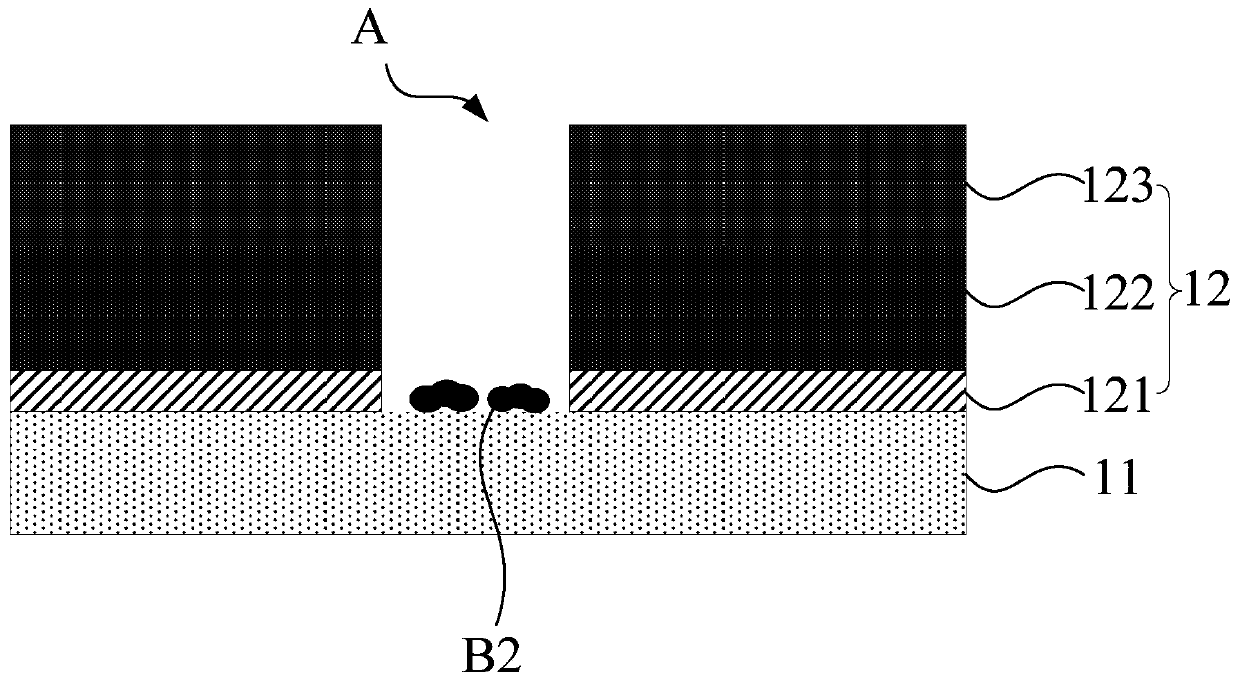

Method for removing polymer

ActiveCN110600376APrevent re-formationGuaranteed performanceSemiconductor/solid-state device manufacturingCompound (substance)Electrical conductor

The invention provides a method for removing a polymer. The method comprises a step of providing a semiconductor substrate, wherein the semiconductor substrate comprises a top metal layer and a passivation layer which are formed in an overlapped mode, an opening is formed in the passivation layer, the opening penetrates through the passivation layer to expose the top metal layer, and the polymer is left at a bottom of the opening, a step of alternately executing a chemical etching process and a physical bombardment process on the semiconductor substrate by taking the passivation layer as a mask so as to etch the polymer at the bottom of the opening. The method for removing the polymer provided by the invention is relatively high in speed, other parts of the semiconductor substrate can be prevented from being damaged, and the performance of the semiconductor substrate is ensured.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for promoting germination of new shoots from latent buds at bare leg parts of carya illinoensis large branches

ActiveCN111357558APromote cryptobud germinationIncrease the number ofFertilising methodsCultivating equipmentsGerminationHickory nut

The invention discloses a method for promoting the germination of new shoots from latent buds at the bare leg parts of carya illinoensis large branches. The method comprises the following steps: (1) applying paclobutrazol to the root soil of a carya illinoensis tree within the first application time; and (2) applying urea to the root soil of the carya illinoensis tree within the second applicationtime. The method can effectively promote the germination of new shoots from latent buds at the bare leg parts of carya illinoensis large branches, the number of grafted fruit branches is increased, meanwhile, the vertical growth characteristic of the new shoots also can be inhibited, the new shoots are prevented from forming bare leg parts again, and the problems of the formation of the bare legparts and low germination rate of the latent buds can be fundamentally solved.

Owner:YUNNAN ACAD OF FORESTRY

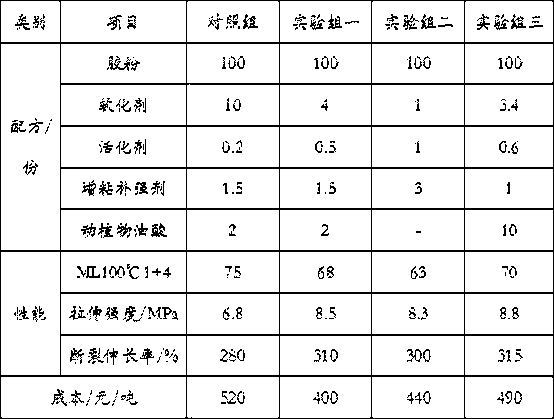

Environment-friendly multifunctional regenerant and preparation method thereof

The invention discloses an environment-friendly multifunctional regenerant and a preparation method thereof. The environment-friendly multifunctional regenerant comprises the following components: inparts by weight, 1-4 parts of a softener and 0.5-1 part of alkylphenol disulfide, wherein the softener is natural phenol, preferably Anacardium occidentale oil or an Anacardium occidentale shell liquid. According to the structural characteristics of different functional auxiliaries including softeners, activators and other auxiliaries, multiple auxiliaries are combined into a uniform and stable additive through the synergistic effect of the functional auxiliaries in the production process of recycled rubber, therefore, the complicated mixing procedure before production is optimized, and convenience for production, use, measurement and transfer is achieved due to the multifunctional regenerant at an easy-flowing liquid state at room temperature.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

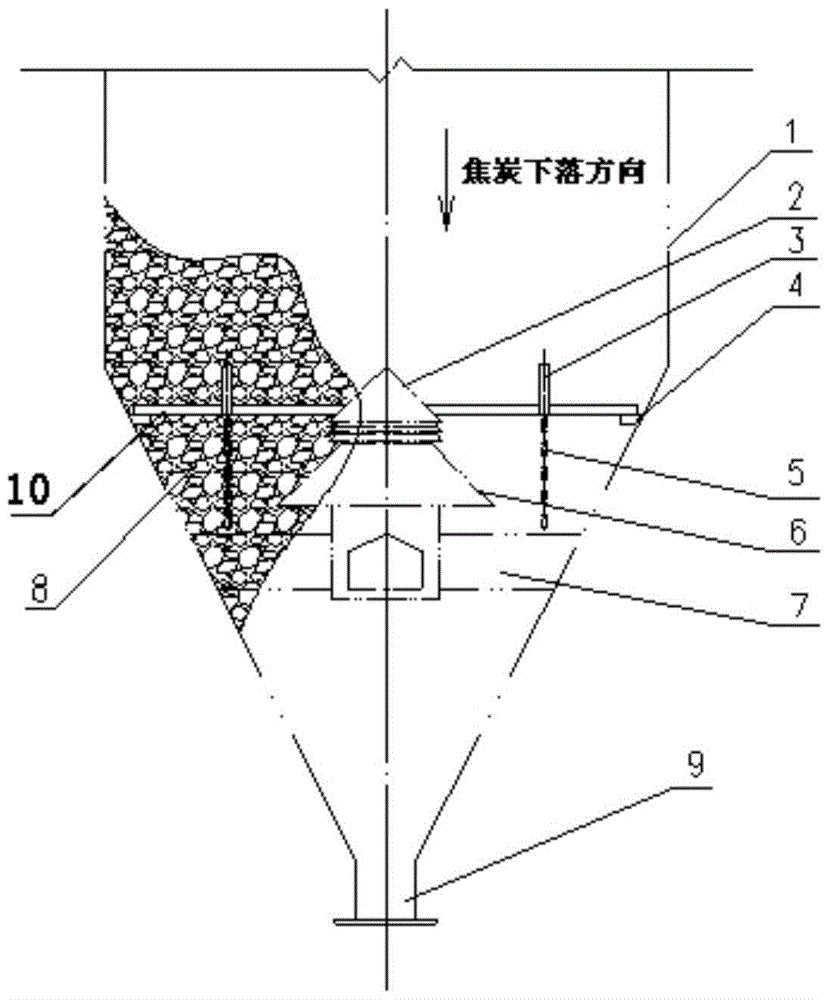

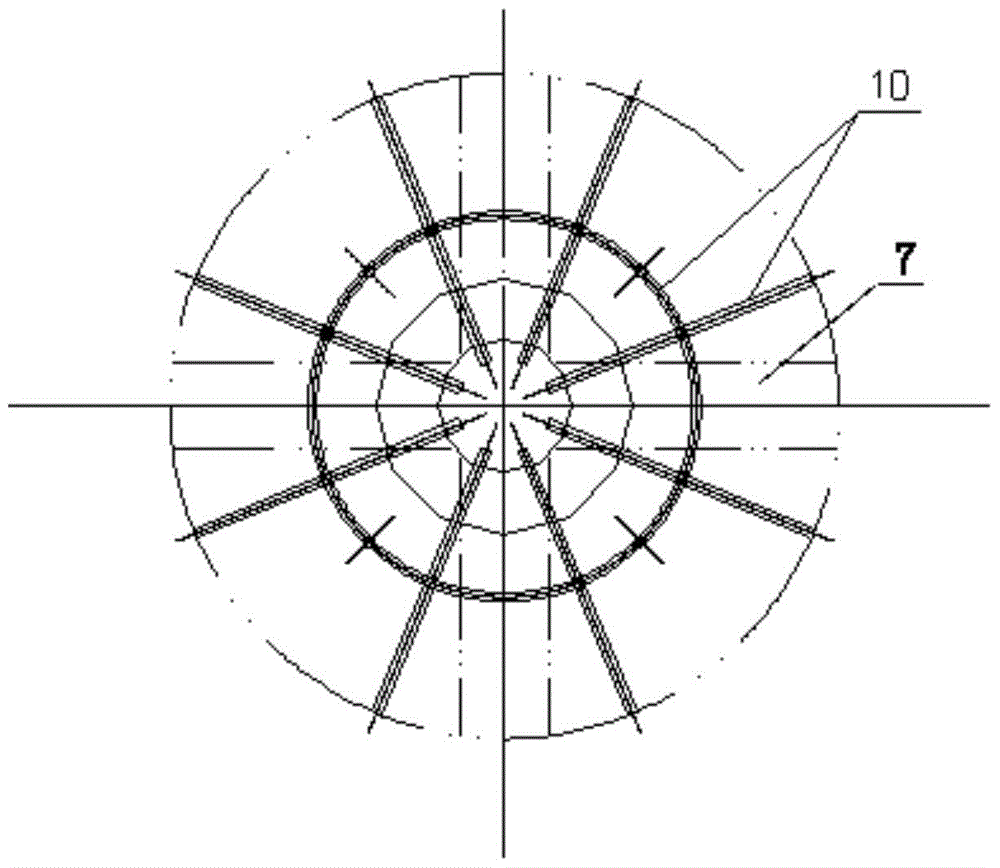

An anti-coke clogging device in a dry quenching furnace

ActiveCN104629778BPrevent re-formationSmooth nestingCoke quenchingCoke oven safety devicesQuenchingMaterials science

The invention relates to a coke plugging prevention device of a dry quenching furnace. A wind cap composed of a small wind cap and a big wind cap is formed in the dry quenching furnace, the wind cap is connected with an air supplying duct arranged in the cone funnel of the dry quenching furnace, a coke plugging prevention device in the dry quenching furnace is arranged at the periphery of the wind cap and comprises blanking crushing bodies, a blanking crushing bracket and unchoking lock chains; the blanking crushing bracket is arranged between the cone funnel of the dry quenching furnace and the air supplying duct, a plurality of blanking crushing bodies are fixed on the blanking crushing bracket, and a plurality of unchoking lock chains overhang below the blanking crushing bracket. The coke plugging prevention device of the dry quenching furnace has the advantages that the compact structure of the coke layer can be broken through the self gravity of the coke layer and the blanking crushing bodies after the coke layer with compact structure contacts the device in the dry quenching furnace, and the unchoking lock chains are used for preventing the coke layer from forming the compact structure again, so that the material can be discharged smoothly, and the harmful effect to the operation control and environment protection emission of the dry quenching furnace main body and the dry quenching furnace system due to the coke collapse phenomenon can be effectively prevented.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Carrier of active ingredient of defoaming agent and preparation method thereof

InactiveCN101831280AReduced stabilityPrevent re-formationDrilling compositionProcess engineeringSlurry

The invention relates to a carrier of an active ingredient of a defoaming agent and a preparation method thereof. The carrier of the active ingredient of the defoaming agent is characterized by comprising the following components in part by weight: 1,000 to 2,000 parts of vegetable fatty acid and 100 to 800 parts of lower fatty alcohol. When in use, the carrier has no side effect on other performance of drilling fluid; the use amount is small; when the addition of the carrier reaches 0.2 percent, the density recovery ratio of the drilling fluid can reach over 98 percent; and the carrier is convenient to use and high in dissolving and dispersing speed and can be added into slurry directly.

Owner:濮阳市诚信钻采助剂有限公司

Comedo removing composition and preparation method thereof

InactiveCN110897902APrevent re-formationEasy to useCosmetic preparationsToilet preparationsBiotechnologyFacial skin

The invention provides a comedo removing composition and a preparation method thereof. The comedo removing composition comprises the following components in parts by weight: 5-15 parts of kaolin, 1-20parts of volcanic ash, 1-5 parts of calcium carbonate, 5-20 parts of zinc oxide and 5-30 parts of a curcuma rhizome extract. The comedo removing composition is effective on comedo in facial skin, canbe used for a long time, and does not harm the skin. Furthermore, the comedo removing composition disclosed by the invention can be used for actively separating out grease, dirt, keratotic suppository and the like in skin pores, can be used for astringing pores, controlling oil secretion, inhibiting bacteria and preventing comedo from being formed again, and is convenient and safe to use and freeof irritation.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

Green cleaning agent for mechanical equipment

InactiveCN107474987APrevents rust from recurringShorten cleaning timeOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsChemistryWater soluble

The invention discloses a green cleaning agent for mechanical equipment. The green cleaning agent is prepared from the following substances in parts by weight: 20 to 24 parts of triethanolamine, 6 parts of EDTA, 1 to 2 parts of a degreasing agent, 5 to 6 parts of degreasing powder, 8 to 10 parts of a surface conditioning agent, 5 to 17 parts of potassium sulfate, 7 to 9 parts of anhydrous sodium sulfate, 3 to 4 parts of potassium nitrate, 16 to 18 parts of sodium nitrite, 1 part of sodium sulfite, 4 to 5 parts of a dispersing agent, 4 parts of a thickening agent, 1 to 3 parts of flame retardant, 1 to 3 parts of stearic acid, 5 to 6 parts of stearate, 2 to 3 parts of stearamide, 4 parts of silicone oil and 11 to 12 parts of oleamide. The green cleaning agent for the mechanical equipment, disclosed by the invention, has the efficacy of high efficiency and easiness in cleaning; in addition, oil stains and rust spots on the surface of the mechanical equipment can be thoroughly cleaned and secondary formation of the rust spots on the surface of the mechanical equipment can be prevented; besides, the cleaning time can be shortened and the working efficiency is improved; furthermore, the green cleaning agent is a water-soluble cleaning agent, and has low corrosion to the equipment, so that safety and reliability in use are realized; the production cost is effectively reduced.

Owner:李刚

Automobile-water-tank cleaning agent and preparing method thereof

InactiveCN105623919AExtended service lifeEasy to useOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsPolyethylene glycolLanolin

The invention discloses an automobile-water-tank cleaning agent and a preparing method thereof, and belongs to the technical field of cleaning agents. The automobile-water-tank cleaning agent is prepared from, by weight, 20-25 parts of coconut residuum, 15-20 parts of dried tea dregs, 10-15 parts of bean pulp, 10-15 parts of beer lees, 8-12 parts of kieselguhr, 6-10 parts of Carbomer resin, 6-10 parts of hydrogenated castor oil, 5-8 parts of flaxseed powder, 5-8 parts of lanolin fatty acid, 4-6 parts of bee wax, 3-5 parts of asbestos wool, 3-5 parts of soda powder, 0.5-1 part of honey, 10-15 parts of polyglycol ether, 20-30 parts of acetone and 120-150 parts of water. By means of the automobile-water-tank cleaning agent, water scale in the water tank can be effectively removed, and secondary erosion of the water tank can be avoided; meanwhile, the automobile-water-tank cleaning agent has the antirust effect, water scale is prevented from being formed again, the water tank is protected accordingly, the service life of the water tank is prolonged, and normal operation of a cooling system is guaranteed.

Owner:ANHUI ZHENHAI HEAVY IND MASCH CO LTD

Environmentally-friendly cleaning agent for mechanical equipment

The invention discloses an environmentally-friendly cleaning agent for mechanical equipment. The environmentally-friendly cleaning agent comprises the following materials in parts by weight: 1-9 parts of wax solvent, 14-25 parts of pickling agent, 1-3 parts of phosphating solution, 1-3 parts of passivation solution, 1-3 parts of vitrification agent, 4-8 parts of calcium hydroxide, 7-10 parts of barium hydroxide octahydrate, 7-16 parts of sodium hydroxide, 5-16 parts of potassium nitrate, 7-15 parts of sodium nitrite, 2-4 parts of sodium sulfite,1-3 parts of dispersant, 1-3 parts of thickener, 4-6 parts of flame retardant, 4-8 parts of stearic acid, 7-14 parts of stearate, 4-15 parts of stearic amide, 1-3 parts of silicone oil and 4-10 parts of oleamide. The environmentally-friendly cleaning agent has a high-efficiency easy-cleaning effect and can be used for completely cleaning oil stains and rust spots on the surface of the mechanical equipment and preventing rust spots from forming on the surface of the mechanical equipment again; by adopting the environmentally-friendly cleaning agent, the cleaning time can also be shortened, and the working efficiency is improved.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

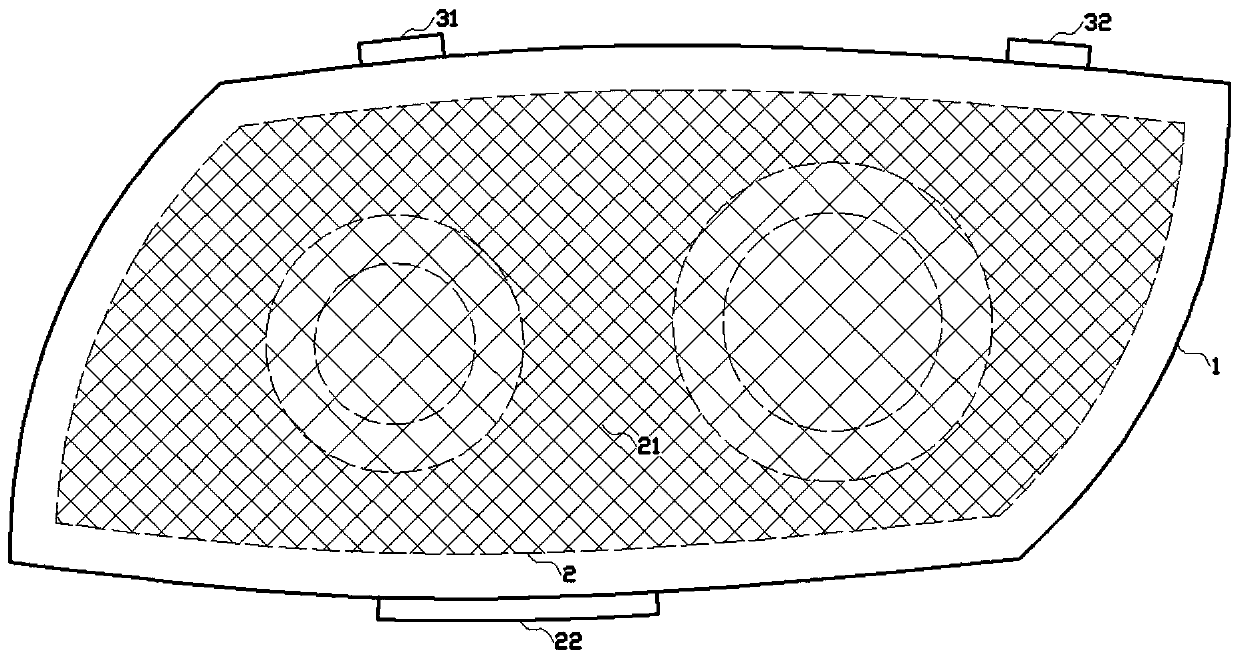

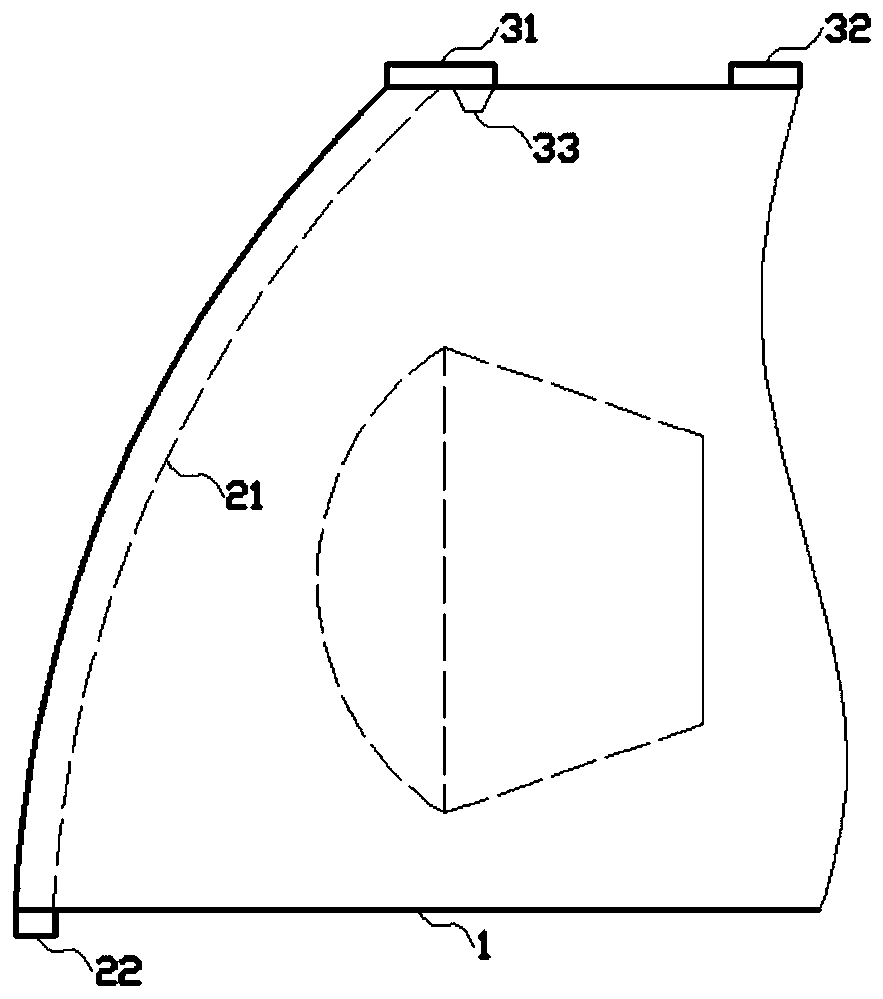

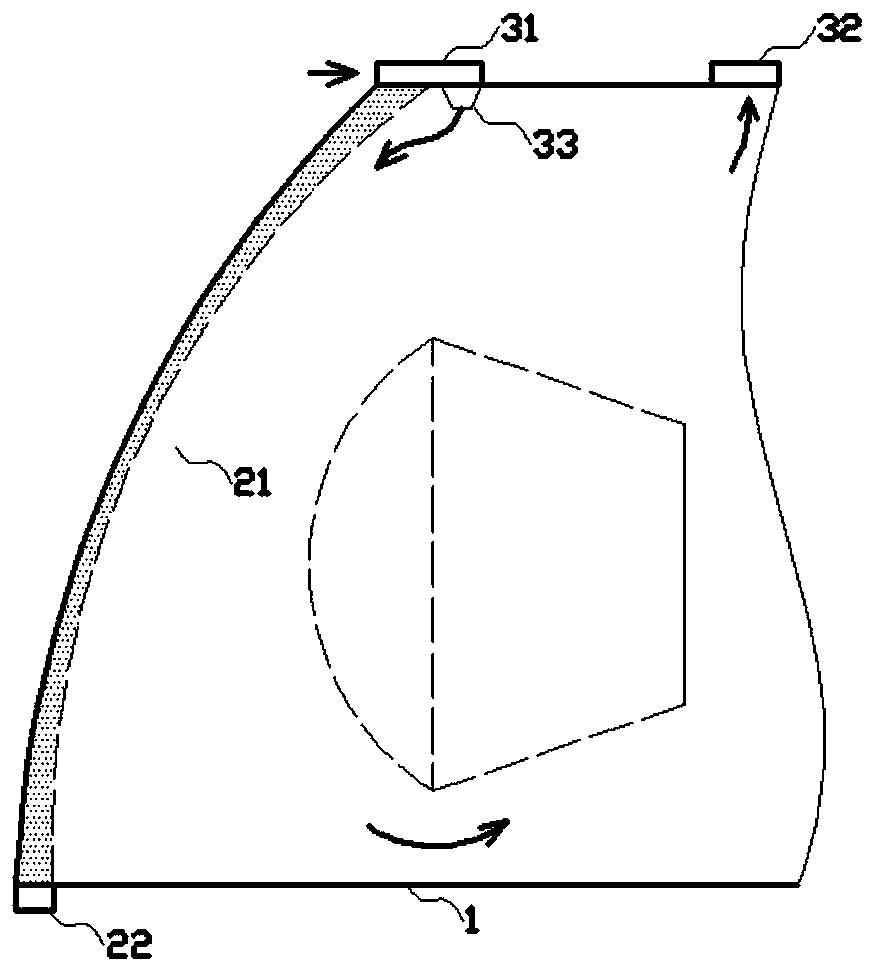

Car headlight automatic demist device

InactiveCN110103895AAvoid formingPrevent re-formationVehicle cleaningEngineeringTemperature difference

The invention provides a car headlight automatic demist device. The car headlight automatic demist device includes a light cover, a demist module and a ventilation module; an air inlet and an air outlet are formed in the upper end of the light cover, and a drainage hole is formed in the lower end of the light cover; the demist module includes a demist net; the demist net includes a detecting module, the detecting module includes a power source and a detecting wire; a drainage tank is arranged at the bottom of the demist net, and a one-way valve is mounted in the drainage hole; and the ventilation module includes an air inlet pipeline and an air outlet pipeline; and electromagnetic valves are correspondingly arranged in the air inlet pipeline and the air outlet pipeline. According to the car headlight automatic demist device, when water mist exists in car headlights, automatic detecting is turned on, thus the water mist in the car headlights can be absorbed by the demist module, thus the water mist quickly forms water drops to be drained out, meanwhile the ventilation module can also accelerate heat dissipation of the car headlights, the temperature difference is quickly eliminated,and the water mist is prevented from forming again.

Owner:陶伟鹏

Drug eluting stone-dissolving bile duct stent and preparation method thereof

InactiveCN102727949AGood radial support performanceGuaranteed unobstructedSurgeryCoatingsDisodium EdetateMedicine

The invention, belonging to the field of biomedicine and physical polymer material, particularly relates to a drug eluting stone-dissolving bile duct stent and a preparation method thereof. The stent is prepared by coating a biodegradable polymer layer containing stone-dissolving drug sodium cholate or / and edetate disodium on the inner surface and outer surface of the uncoated stent, wherein the ratio of sodium cholate to edetate disodium is 0-1mol:0-1mol. Clinical outcomes show that the stone-dissolving bile duct stent of the invention has good radial supporting performance, can keep the bile duct open, has good biocompatibility, and lets almost no internal inflammation generate. Simultaneously, sodium cholate or / and edetate disodium slowly released by the polymer layer containing drugs can dissolve the formed stones and can prevent the re-formation of stones.

Owner:上海交通大学附属第一人民医院

Environment-friendly cleaning agent

InactiveCN107354012APrevents rust from recurringShorten cleaning timeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryWater soluble

The invention discloses an environment-friendly cleaning agent, which is prepared from the following substances in parts by weight: 33 parts of triethanolamine, 8 parts of EDTA, 10 parts of degreasing agents, 13 parts of degreasing powder, 17 parts of surface conditioners, 3 parts of potassium sulphate, 18 parts of anhydrous sodium sulfate, 2 parts of potassium nitrate, 5 parts of sodium nitrite, 1 part of sodium sulfite, 7 parts of dispersing agents, 5 parts of thickening agents, 8 parts of fire retardants, 9 parts of stearic acid, 4 parts of stearate, 16 parts of stearamide, 5 parts of silicone oil and 13 parts of oleamide. The efficient and easy-to-clean effects are achieved on mechanical equipment, so that the cleaning on the oil stain and rust spots on the surface of the mechanical equipment is thorough; the formation of the rust spots again on the surface of the mechanical equipment can be prevented; the cleaning time can also be shortened; the work efficiency is improved; the cleaning agent is a water-soluble cleaning agent; the corrosion on the equipment is low; the production cost is effectively reduced; the use is safe and reliable.

Owner:李刚

Mechanical equipment cleanser

InactiveCN103484260AEfficient and easy to cleanWash thoroughlyOrganic detergent compounding agentsSurface-active detergent compositionsGlycerolMechanical equipment

The invention discloses a mechanical equipment cleanser which comprises the following components in parts by weight: 25-32 parts of triethanolamine, 1-5 parts of EDTA (ethylene diamine tetraacetic acid), 3-8 parts of oil removal agent, 7-12 parts of oil removal powder, 11-15 parts of surface conditioner, 8-10 parts of potassium sulfate, 10-16 parts of anhydrous sodium sulfate, 7-13 parts of ammonia water, 7-13 parts of aluminum hydroxide, 9-13 parts of hollow glass microsphere, 11-18 parts of sorbitol, 7-10 parts of polypropylene, 9-16 parts of polyethylene, 1-8 parts of glycerol, 7-16 parts of benzophenone, 1-7 parts of coupling agent and 1-2 parts of sodium dodecyl benzene sulfonate. The cleanser can be used for efficiently and easily cleaning mechanical equipment, so that the oil stain and rusty stain on the mechanical equipment surface are thoroughly removed; the cleanser can avoid forming rusty stain again on the mechanical equipment surface, shorten the cleaning hour and enhance the work efficiency; and the cleanser is water-soluble, has low corrosivity for the equipment, effectively lowers the production cost, and is safe and reliable to use.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

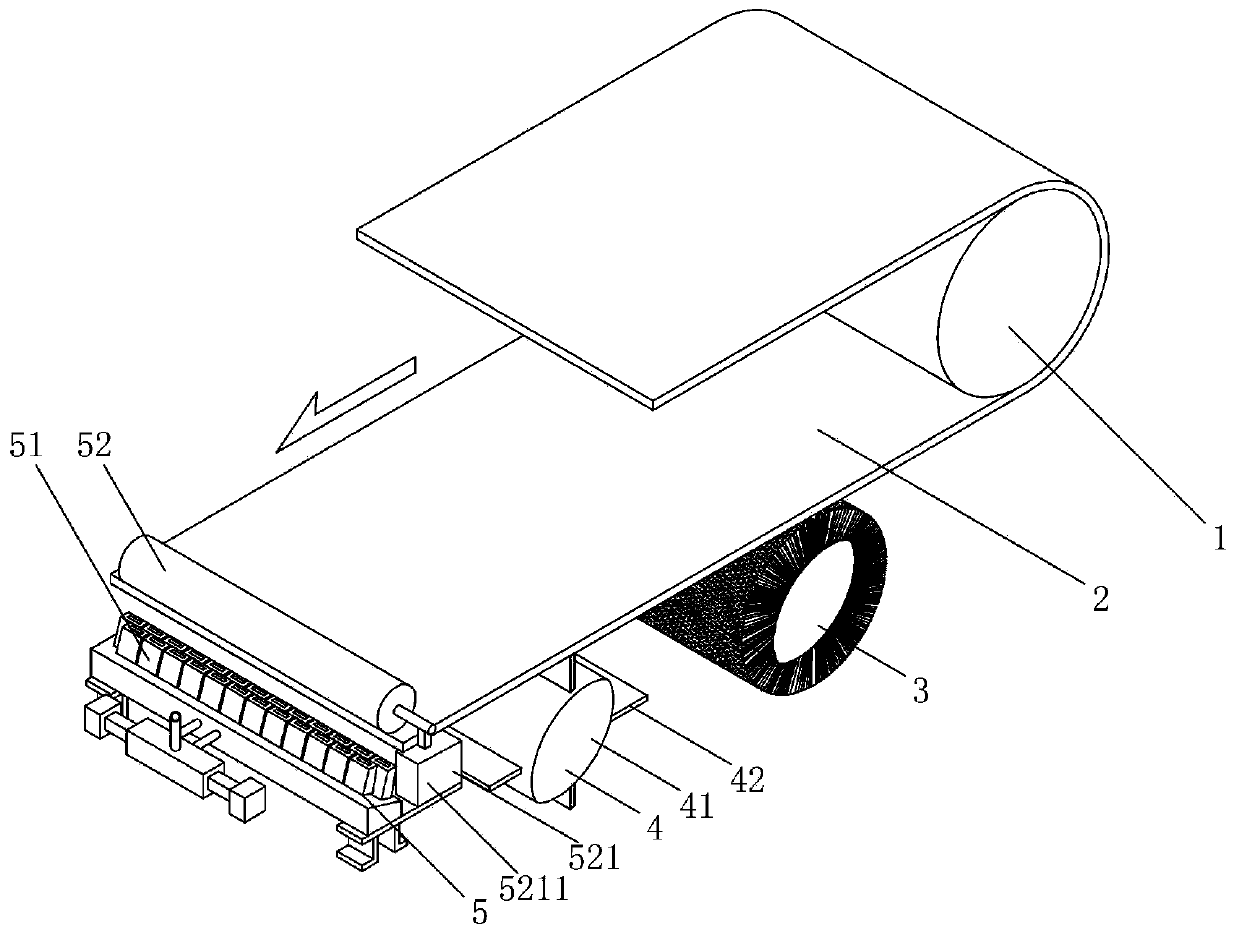

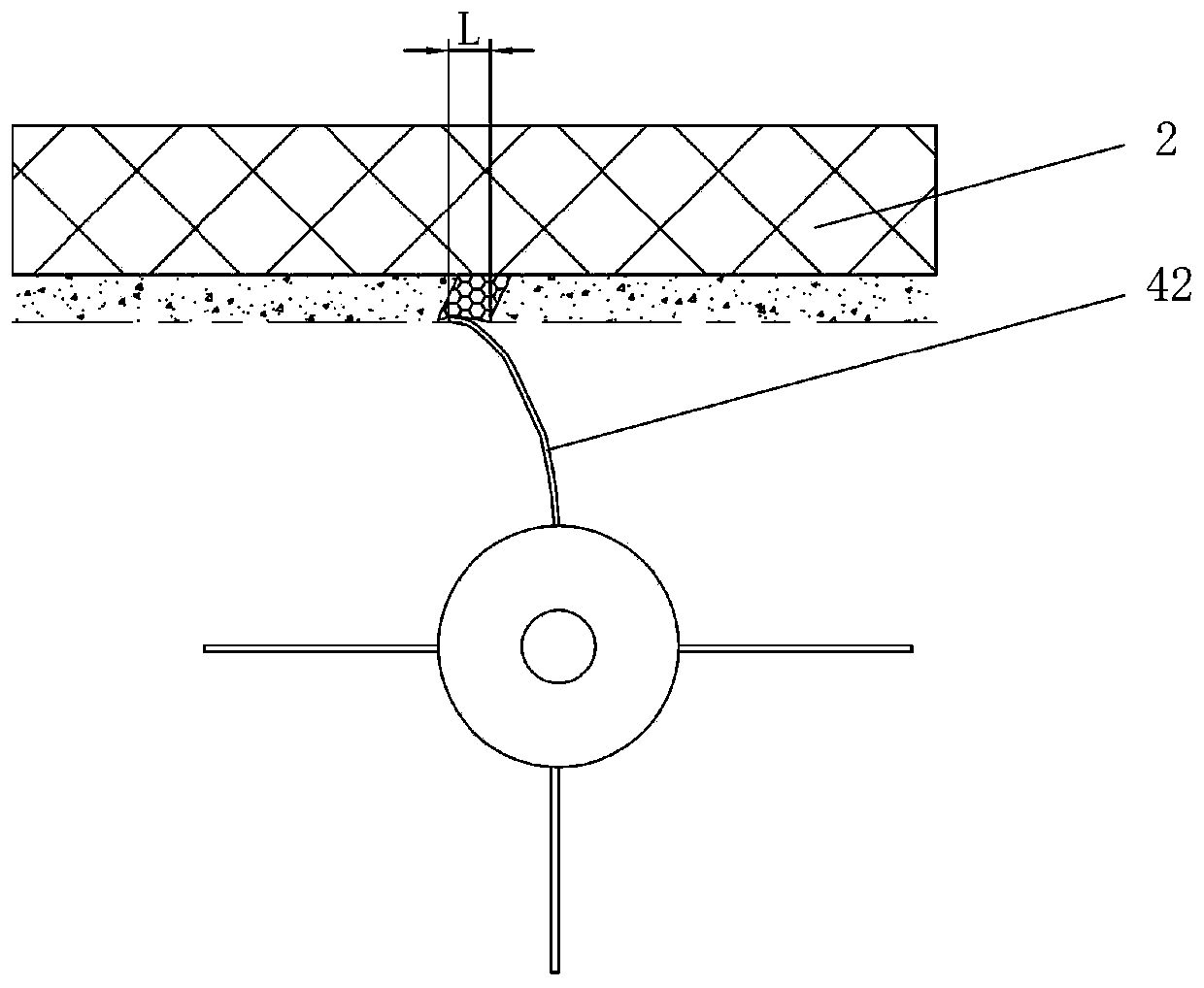

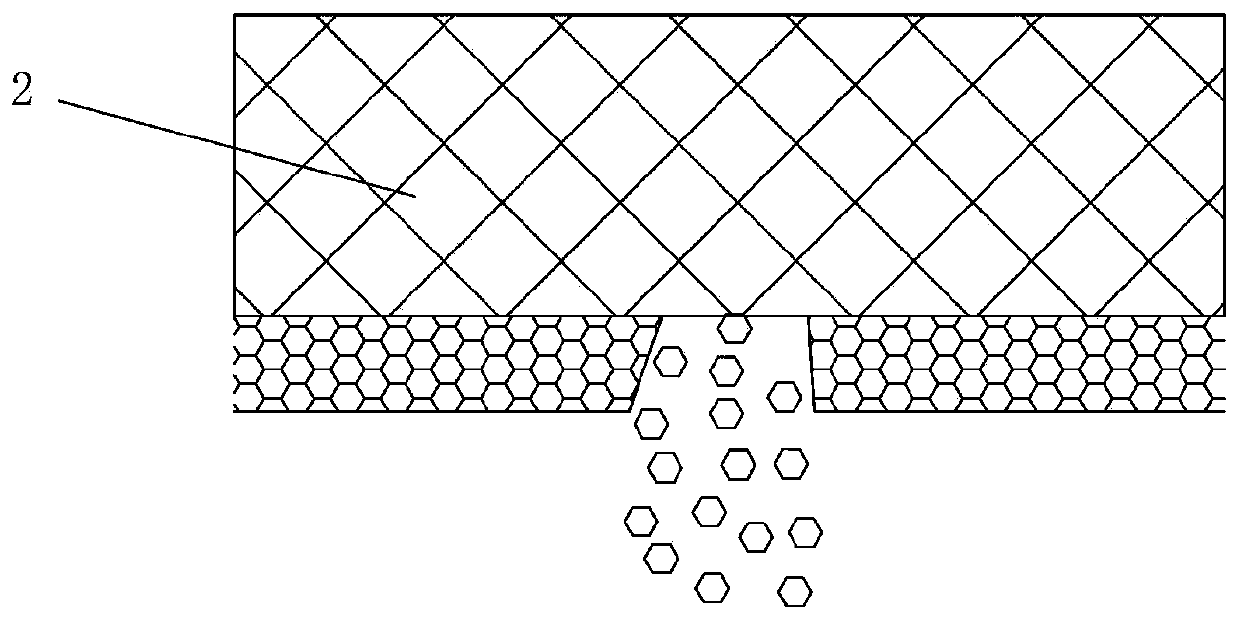

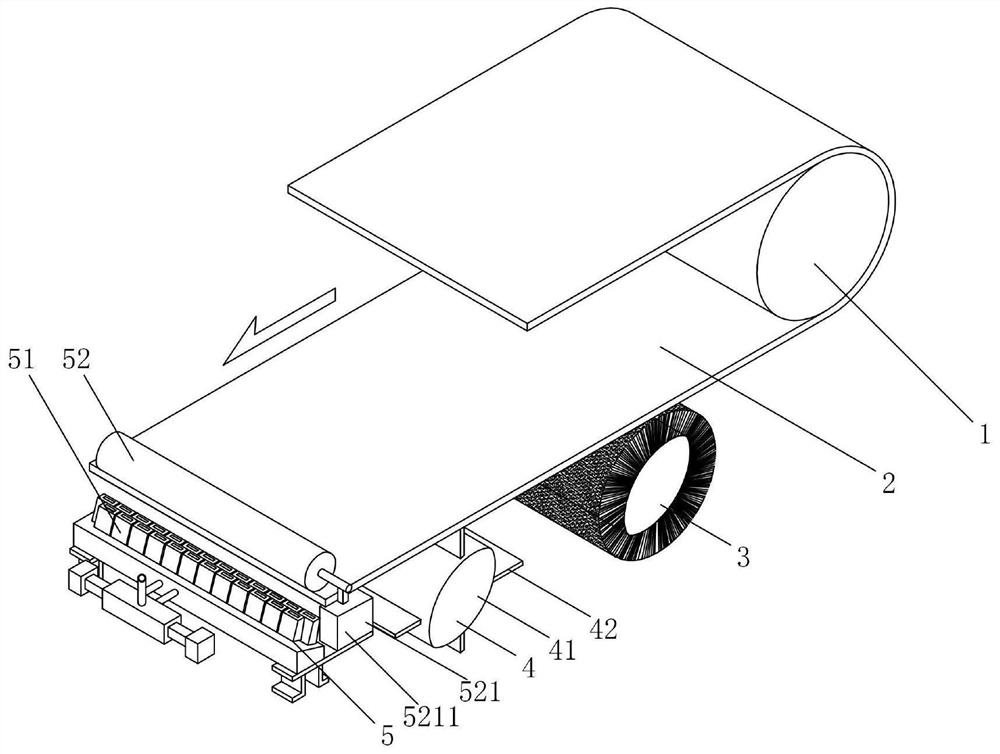

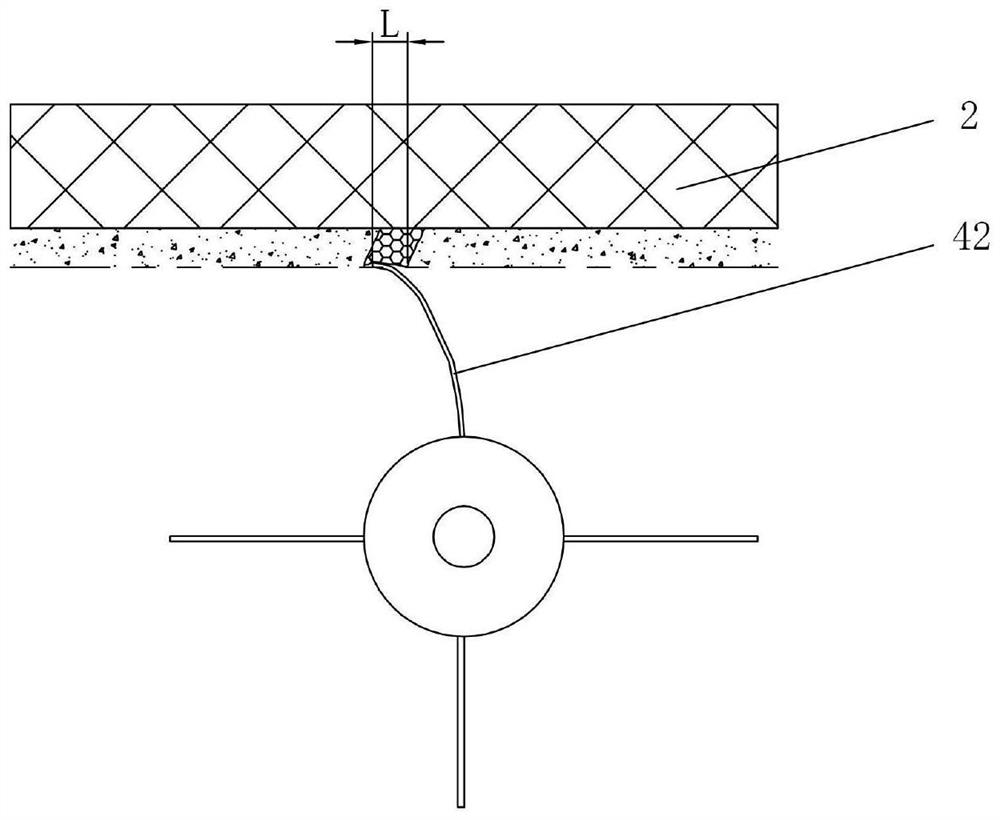

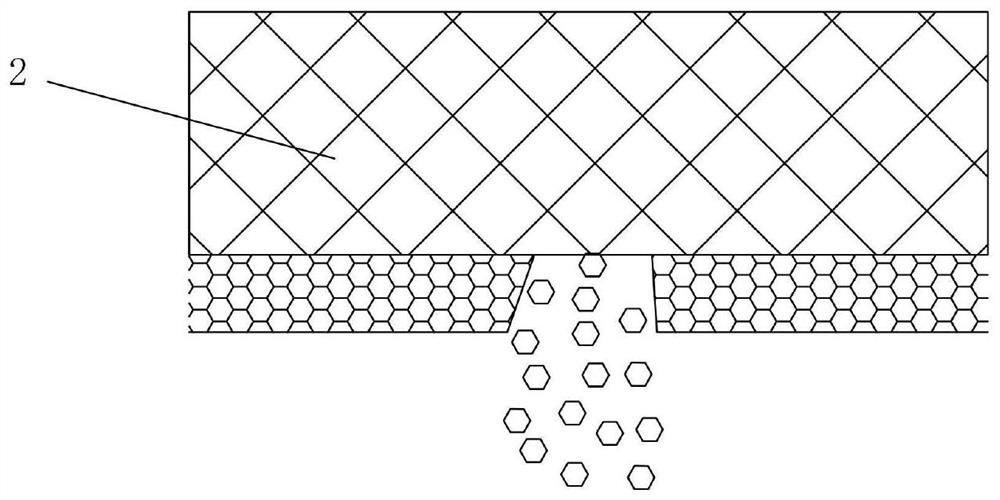

Multi-mechanism combined type belt adhesive material removal device

ActiveCN111115168AReasonable arrangementReduce stickyCleaningStructural engineeringAdhesive materials

The invention discloses a multi-mechanism combined type belt adhesive material removal device which is arranged under a return belt at a discharging roller. The multi-mechanism combined type belt adhesive material removal device comprises a roller brush, a consolidation layer stripping device and an air blade cutting device, wherein the roller brush, the consolidation layer stripping device and the air blade cutting device are arranged in sequence relative to the discharging roller from near to far along the layout direction of the return belt; the consolidation layer stripping device comprises a stripping roller and a stripping whip, and the axis of the stripping roller is parallel with the axis of the discharging roller; and one end of the stripping whip is fixedly arranged on the stripping roller, and the other end of the stripping whip lashes the surface of the return belt under the driving of the rotary movement of the stripping roller. The multi-mechanism combined type belt adhesive material removal device is simple and practical, has efficient cleaning and can prevent the material from sticking to the belt.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Energy-saving environment-friendly mechanical equipment cleanser

InactiveCN103484262AEfficient and easy to cleanWash thoroughlyNon-ionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsGlycerolMechanical equipment

The invention discloses an energy-saving environment-friendly mechanical equipment cleanser which comprises the following components in parts by weight: 5-7 parts of zirconium oxide, 11-21 parts of silicon dioxide, 5-9 parts of hydrogen peroxide, 15-25 parts of salicylate, 7-16 parts of vinyl bis-stearamide, 9-13 parts of glycerol monostearate, 9-14 parts of glyceryl tristearate, 1-3 parts of reducer, 5-8 parts of softener, 7-10 parts of impurity removal agent, 11-18 parts of treating agent, 3-5 parts of titanium dioxide, 11-18 parts of sorbitol, 7-10 parts of polypropylene, 9-16 parts of polyethylene, 1-8 parts of glycerol, 7-16 parts of benzophenone, 1-7 parts of coupling agent and 1-2 parts of sodium dodecyl benzene sulfonate. The cleanser can be used for efficiently and easily cleaning mechanical equipment, so that the oil stain and rusty stain on the mechanical equipment surface are thoroughly removed; and the cleanser can avoid forming rusty stain again on the mechanical equipment surface, shorten the cleaning hour and enhance the work efficiency.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Purification material for controlling air pollution

ActiveCN110270221AStrong enrichment abilityPrevent re-formationOther chemical processesDispersed particle separationFiberMicrosphere

The invention relates to a purification material for controlling air pollution. A biomass microsphere is formed through a colloidal biomass material loaded catalyst, and colloidal biomass is formed through starch and plant fiber gumming; the catalyst is a doped titanium dioxide-silica gel catalyst. The purification material mainly adopts the biomass material, the cost is low, environmental friendliness is achieved, and secondary pollution cannot be caused by using the material. The preparation method can be continuously implemented, implement and control are conducted easily, and industrial production is facilitated.

Owner:李洪芳

A purification material for air pollution control

ActiveCN110270221BStrong enrichment abilityPrevent re-formationOther chemical processesDispersed particle separationPtru catalystMicrosphere

The invention relates to a purification material for controlling air pollution, which is a biomass microsphere formed by carrying a catalyst on a colloidal biomass material. The colloidal biomass is colloidized from starch and plant fibers; the catalyst is Doped titania-silica gel catalyst. The purification material is mainly a biomass material, has low cost, is green and environmentally friendly, and will not cause secondary pollution when used. The preparation method of the invention can be operated continuously, is easy to implement and control, and is beneficial to industrialized production.

Owner:李洪芳

A method of controlling air pollution

ActiveCN110270222BStrong enrichment abilityPrevent re-formationOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMicrosphere

The invention relates to a method for controlling air pollution. In heavily polluted industrial areas, aircrafts are used to spray purification materials with high pressure. After spraying for a period of time, air pollutants are adsorbed or degraded, and air quality is improved; the purification materials are composed of Biomass microspheres formed by colloidal biomass material loaded with a catalyst, the colloidal biomass is gelatinized from starch and plant fibers; the catalyst is a doped titanium dioxide-silica gel catalyst. The purification material is mainly a biomass material, has low cost, is green and environmentally friendly, and will not cause secondary pollution when used. The preparation method of the invention can be operated continuously, is easy to implement and control, and is beneficial to industrialized production.

Owner:北京中环高科环境治理有限公司

Surface three-step nitridation method of aluminium and aluminium alloy

InactiveCN102943231BEfficient removalStrong penetrating powerSolid state diffusion coatingOxygen5052 aluminium alloy

The invention relates to a surface three-step nitridation method of aluminium and aluminium alloy, comprising the following steps: 1, removing surface oxide-films; 2, conducting surface nitridation treatment, wherein the step 1 successively comprises: pretreating, conducting a first zinc immersion, washing, removing zinc, conducting a secondary zinc immersion, and washing and drying; and the step 2 successively comprises: discharging oxygen, heating up to let the furnace temperature be 300 DEG C, and controlling the ammonia dissociation rate below 10%; heating up to 560-590 DEG C for the first time; nitriding for the first time at the furnace temperature of 560-590 DEG C; heating up to 620-640 DEG C for the second time; conducting secondary nitriding at the furnace temperature of 620-640 DEG C; cooling to let the furnace temperature be 570-600 DEG C; nitriding for the third times at the furnace temperature of 570-600 DEG C; and denitriding at the furnace temperature of 570-600 DEG C. According to the invention, the surface dense oxide-films of aluminium and aluminium alloy can be effectively removed, the infiltration of nitrogen atoms is benefited, and nitridation treatment can be conducted by using a common gas nitriding furnace, thus the production cost is low, the operation is simple, the adaptability is wide, and the infiltrated layer has good quality.

Owner:JIANGSU UNIV

A multi-mechanism combined belt sticky removal device

The invention discloses a multi-mechanism combined belt sticky material removal device, which is installed under the return belt at the unloading roller, includes a roller brush, a consolidation layer peeling device and an air knife cutting device, and is arranged along the direction of the return belt The roller brush, the consolidated layer peeling device and the air blade cutting device are arranged in sequence from near to far relative to the discharge roller; The axes are parallel to each other. One end of the stripping whip is fixedly installed on the stripping roller, and the other end is driven by the rotary motion of the stripping roller to strike the surface of the return belt. The multi-mechanism combined type belt sticky removal device of the present invention has the advantages of being simple and practical, highly efficient cleaning and capable of preventing belt sticky material, and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

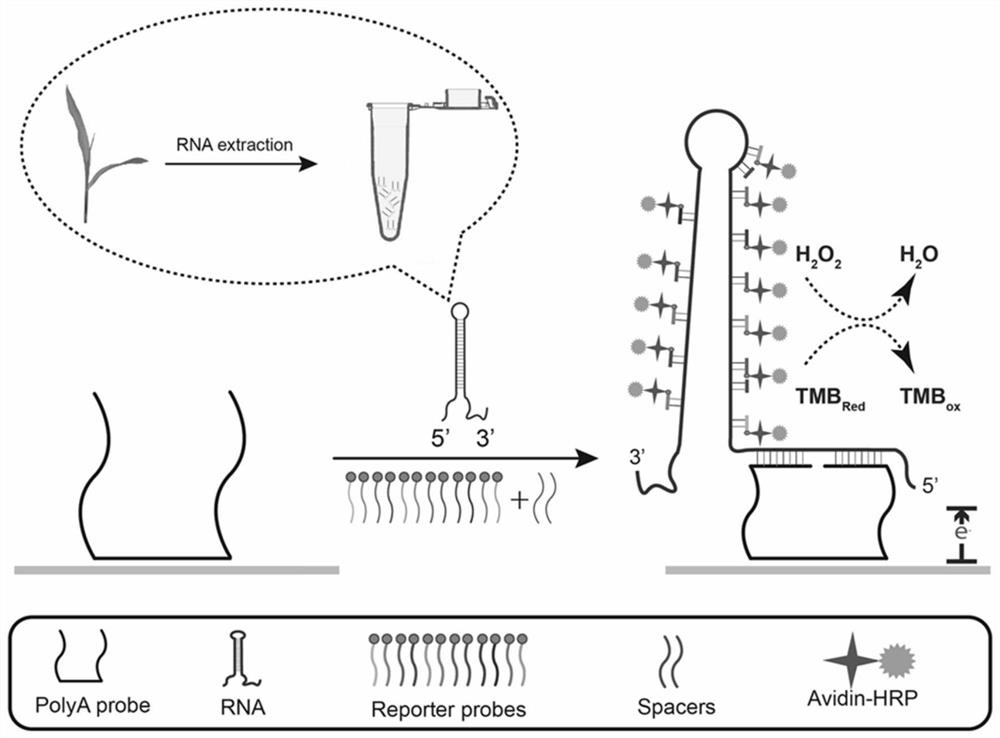

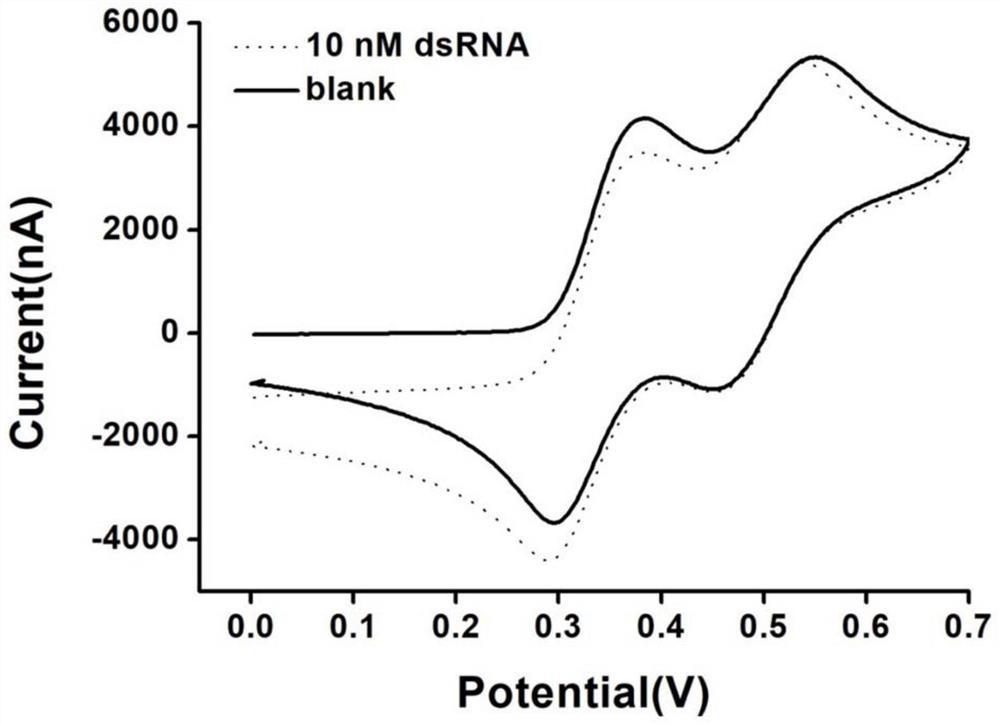

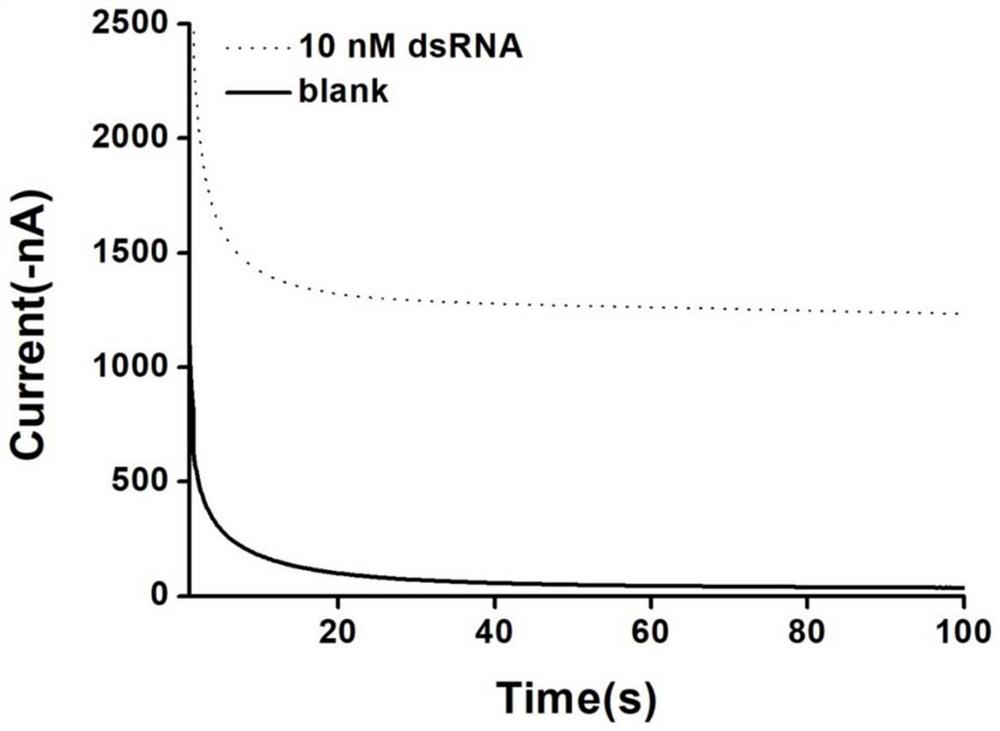

Electrochemical sensor based on triblock probe and application of electrochemical sensor in detection of transgenic double-stranded RNA

ActiveCN112162027AImprove capture abilityStable detectionMicrobiological testing/measurementMaterial electrochemical variablesNucleic acid sequencingDouble stranded

The invention provides an electrochemical sensor based on a triblock probe and application of the electrochemical sensor in detection of transgenic double-stranded RNA. The electrochemical sensor comprises a gold electrode and a triblock probe; the triblock probe comprises PolyA, and a first capture probe and a second capture probe which are connected with the PolyA; the first capture probe and the second capture probe comprise a section of nucleic acid sequence complementary with the transgenic double-stranded RNA; and the triblock probe is modified on the surface of the gold electrode through the adsorption effect of PolyA and the gold electrode. The surface of the electrochemical sensor is modified with the triblock probe, specific, sensitive and stable transgenic double-stranded RNA detection is achieved, and the electrochemical sensor has the advantages of being high in sensitivity, short in consumed time, low in cost, portable and the like.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com