A multi-mechanism combined belt sticky removal device

A cleaning device and a combined technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of poor cleaning effect, no cleaning of belt consolidation layer, etc., and achieve easy cleaning, less sticky materials, and layout methods reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

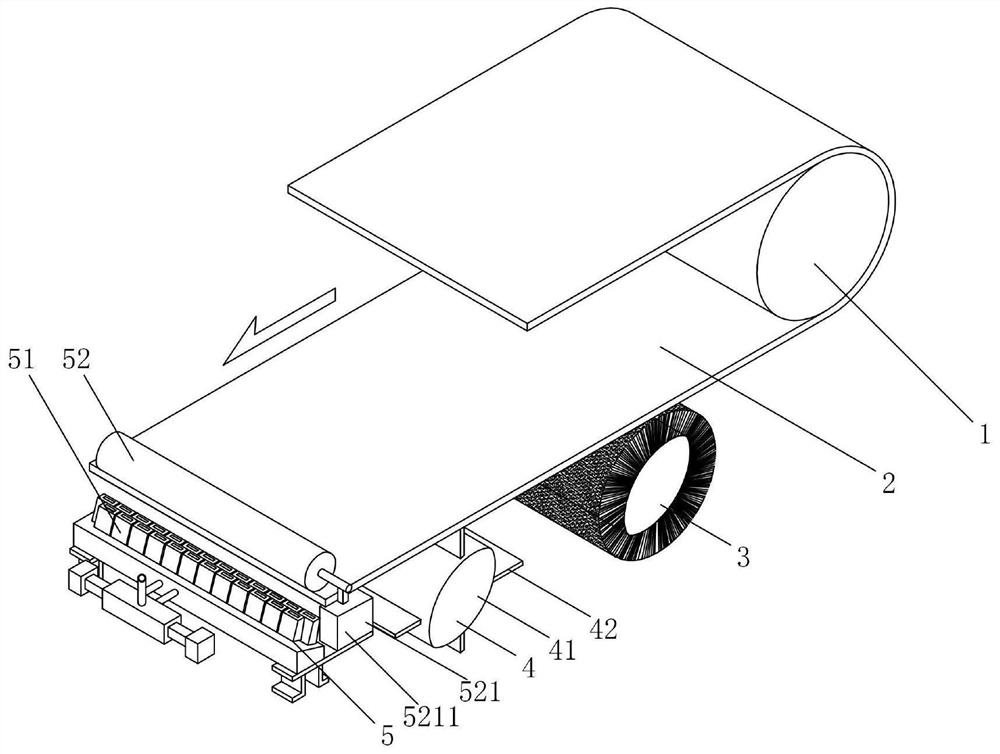

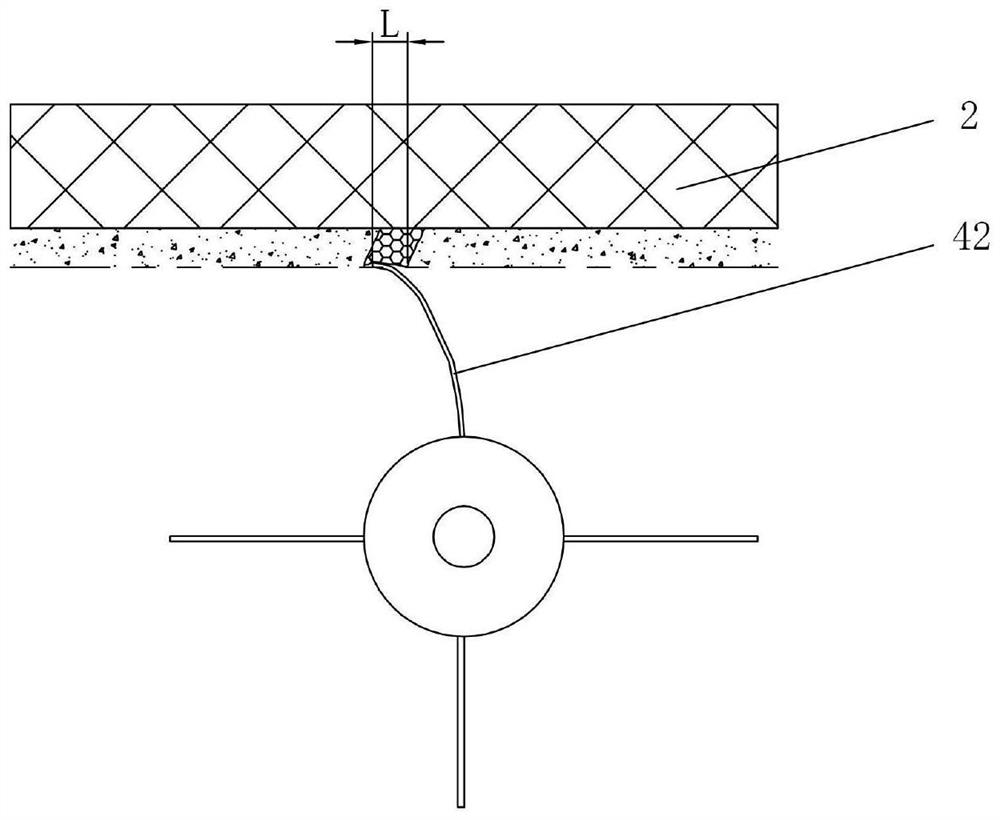

[0028] Such as figure 1 As shown, the multi-mechanism combined belt adhesive removal device of this embodiment is installed under the return belt 2 at the unloading roller 1, and includes a roller brush 3, a consolidated layer stripping device 4 and an air knife cutting device 5, and Along the arrangement direction of the return belt 2, the roller brush 3, the consolidated layer peeling device 4 and the air knife cutting device 5 are arranged in sequence relative to the discharge roller 1 from near to far; the consolidated layer peeling device 4 includes a peeling roller 41 and a peeling whip 42, The axis of the stripping roller 41 is parallel to the axis of the unloading roller 1. One end of the stripping whip 42 is fixedly mounted on the stripping roller 41, and the other end is driven by the rotary motion of the stripping roller 41 to strike the surface of the return belt 2.

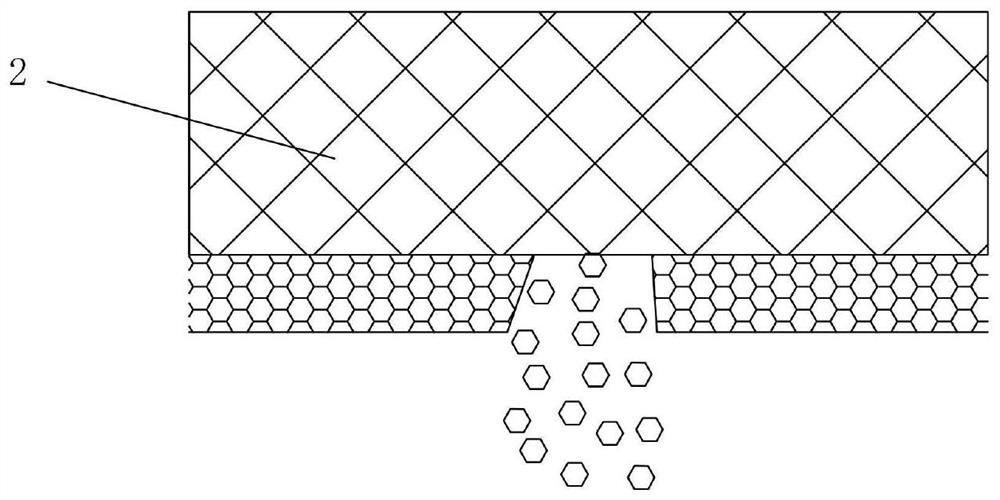

[0029] Such as figure 2 and image 3 As shown, after the belt is unloaded by the discharge roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com