Environment-friendly multifunctional regenerant and preparation method thereof

A multifunctional, rejuvenating agent technology, applied in recycling technology, plastic recycling, etc., can solve the problems of poor activation effect, inconvenient use, and unsatisfactory performance indicators of recycled rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An environment-friendly multifunctional regeneration agent, comprising the following components in parts by weight: 4 parts of softening agent, 0.5 parts of alkylphenol disulfide, 1.5 parts of thickening and strengthening agent, 2 parts of animal and vegetable oleic acid, and the softening agent is natural Phenols, cashew nut oil is preferred in this embodiment, and the alkylphenol disulfide is a mixture of one or more of activator 420, activator 450, activator 480, activator 560, and activator 910. Among them, activator 480 is preferred, rosin is the thickening and reinforcing agent, and animal and vegetable oleic acid is pine tar, tall oil, palm oil, etc., and vegetable oil residue or vegetable asphalt produced by other industries. In this embodiment, palm oil is preferred.

[0021] Preparation method: Heat the cashew nut oil to 130°C in a stirring tank, melt the alkylphenol disulfide in an oven at 80°C to a liquid state that is easy to flow, and then add the two into ...

Embodiment 2

[0023] An environment-friendly multifunctional regeneration agent, comprising the following components in parts by weight: 1 part of softening agent, 1 part of alkylphenol disulfide, 3 parts of thickening and reinforcing agent, softening agent is cashew nut oil, alkylphenol disulfide Choose activator 420 as the sulfide, and choose rosin as the thickening and reinforcing agent.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] An environment-friendly multifunctional regeneration agent, comprising the following components in parts by weight: 3.4 parts of softening agent, 0.6 part of alkylphenol disulfide, 1 part of thickening and strengthening agent, 10 parts of animal and vegetable oleic acid, and the softening agent is cashew nut Shell liquid, alkylphenol disulfide chooses activator 910, thickener chooses rosin, animal and vegetable oleic acid chooses pine tar.

[0027] The preparation method is the same as in Example 1.

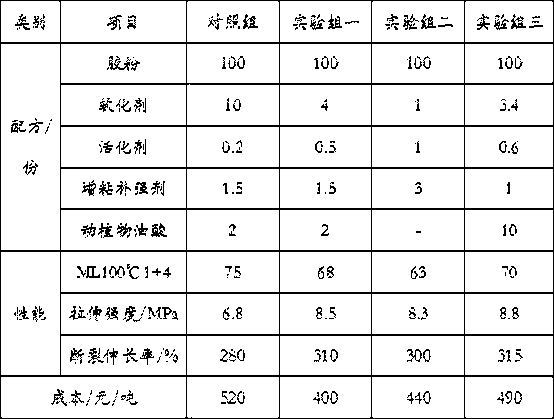

[0028] Comparative experiment one:

[0029] The control group used regenerants: in parts by weight, 10 parts of softener, 0.2 parts of alkylphenol disulfide, 1.5 parts of thickener and reinforcing agent, and 2 parts of animal and vegetable oleic acid were added to the reclaimed rubber powder respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com