Compound type vegetable oil lubricating agent for drilling fluid and preparation method thereof

A vegetable oil and lubricant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of not being able to meet the low-cost requirements of lubricants, not being suitable for large-scale production and application, and increasing production costs, and achieve low fluorescence levels , good bearing and thermal stability, and the effect of preventing drill sticking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

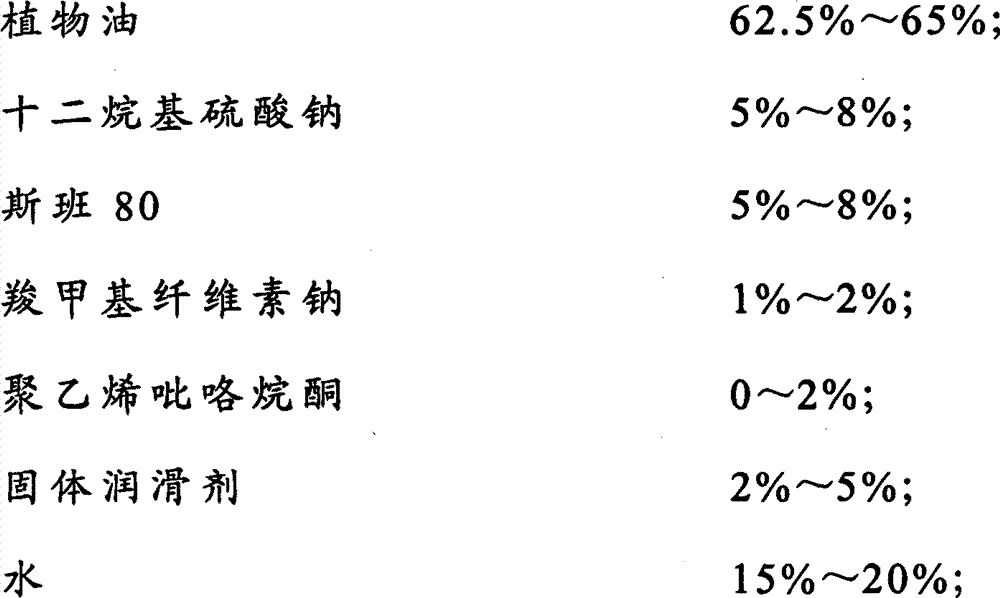

[0029] Take 5g of sodium lauryl sulfate and add it to 10ml of water, stir to dissolve it completely, then add 1g of sodium carboxymethylcellulose and 1g of polyvinylpyrrolidone in turn, stir again to dissolve it completely, and get a mixed solution for later use; take 40g of rapeseed oil , add 5g of Sipan 80, ultrasonically disperse at 60°C for 30 minutes, take 2g of natural graphite and add it, continue ultrasonically dispersing for 30 minutes; / min) and stirred for 8 hours to obtain a compound vegetable oil lubricant for drilling fluid.

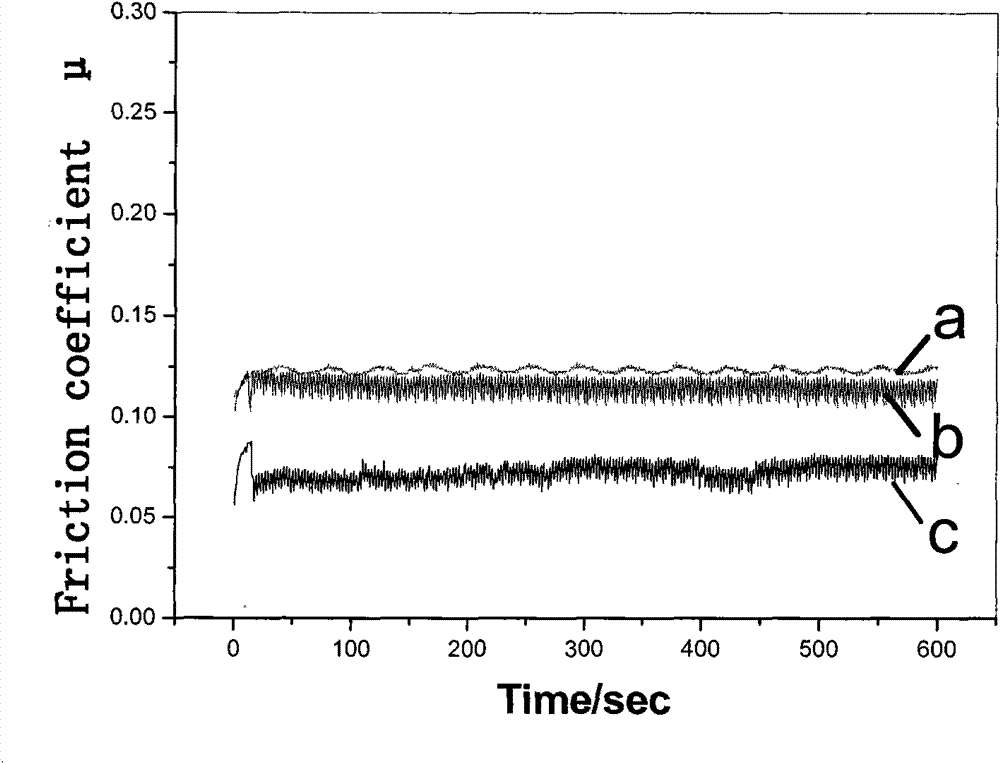

[0030] Measure the friction performance curve of the above-mentioned composite vegetable oil lubricant for drilling fluid, and compare it with the commercially available common vegetable oil lubricant and the lubricant for common drilling fluid. The obtained results are as follows figure 1 As shown, among the figure a is the friction performance curve of ordinary vegetable oil lubricant, b is the friction performance curve of ordinary drill...

Embodiment 2

[0032] Take 5g of sodium lauryl sulfate and add it to 10ml of water, stir to dissolve it completely, add 2g of sodium carboxymethylcellulose, and stir again to dissolve it completely to obtain a mixed solution for later use; take 40g of soybean oil, add 5g of Sipan 80 , ultrasonically disperse at 60°C for 30 minutes, add 1.5g of serpentine into it, and continue to ultrasonically disperse for 30 minutes; add the mixed solution to the above-mentioned completely dispersed soybean oil, and stir in a high-speed mixer (rotating speed is 1000r / min) for 8 hours, the compound vegetable oil lubricant for drilling fluid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com