Grouped washing pressure testing method and grouped washing pressure testing device for water cooling pipeline at bottom of blast furnace

A technology of water-cooled pipes and water-cooled pipes, which is applied to cooling devices and other directions, can solve problems such as increased construction costs and increased workload, and achieve the effects of reducing engineering construction costs, saving time, and reducing installation and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

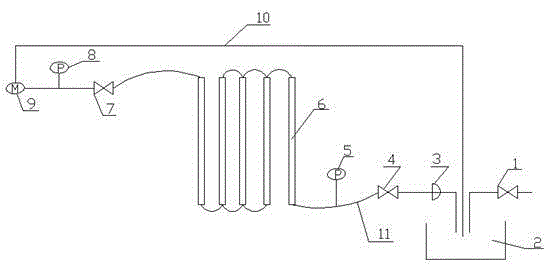

[0013] Refer to the attached drawings, the pressure test method for grouped flushing of water-cooled pipes at the bottom of a blast furnace includes the following process steps:

[0014] 1. The water delivery truck transports the clean water to the pressure test site, opens the water delivery truck valve 1, and injects the clean water into the water collection tank 2 until the water collection tank is full, and installs the charging pump 9 and the first pressure gauge 8 on the water inlet pipe 10 in sequence And the water inlet valve 7, the water inlet of the water inlet pipe is connected with the water collection tank, and the outlet of the water inlet pipe is connected with the water inlet of the pressure component 6; the second pressure gauge 5, the water outlet valve 4 and the filter screen 3 are installed on the water outlet pipe 11 in sequence , The water inlet of the water outlet pipe is connected with the water outlet of the pressing member, the water outlet of the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com