AI image recognition sensor probe-based edge compensation control system

A sensor probe and image recognition technology, which is applied in image communication, character and pattern recognition, TV system components, etc., can solve the problems that the motor driver cannot detect the accurate commutation signal, the positioning accuracy is not high enough, and the delay is high. The effect of friendly human-computer interaction, reducing the installation volume and improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

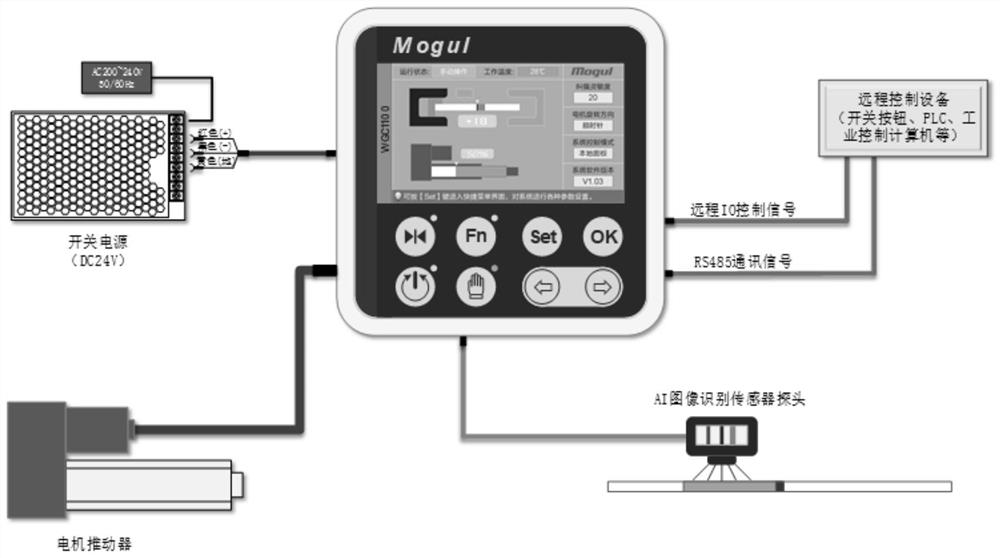

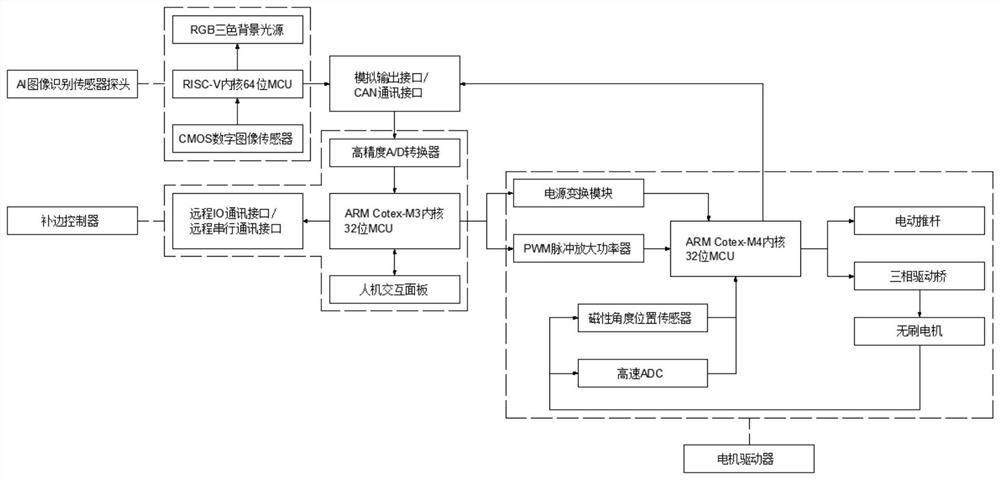

[0023] see Figures 1 to 2 , In the embodiment of the present invention, an AI-based image recognition sensor probe edge compensation control system includes an AI image recognition sensor probe, a motor driver and an edge compensation controller. The AI image recognition sensor probe includes an image acquisition element, an RGB three-color background light source and RISC-V core 64-bit MCU, the output terminal of the image acquisition element is electrically connected to the input terminal of the RISC-V core 64-bit MCU, and the input terminal of the RGB three-color background light source is electrically connected to the output terminal of the RISC-V core 64-bit MCU. The motor driver includes an electric push rod and a drive board, the output end of the electric push rod is fixedly connected to the shell of the brushless motor, the drive board is integrally installed on the shell of the brushless motor, and the drive board includes a power conversion module, ARM cortex -M4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com