Floors installed without joists

A technology without keel and floor, applied in the direction of floor, building, building structure, etc., can solve the problems of poor insect control effect, affecting installation operation, easy dispersion of insect repellant in the air, etc., to save wood, easy to operate, support High strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described below in conjunction with the drawings.

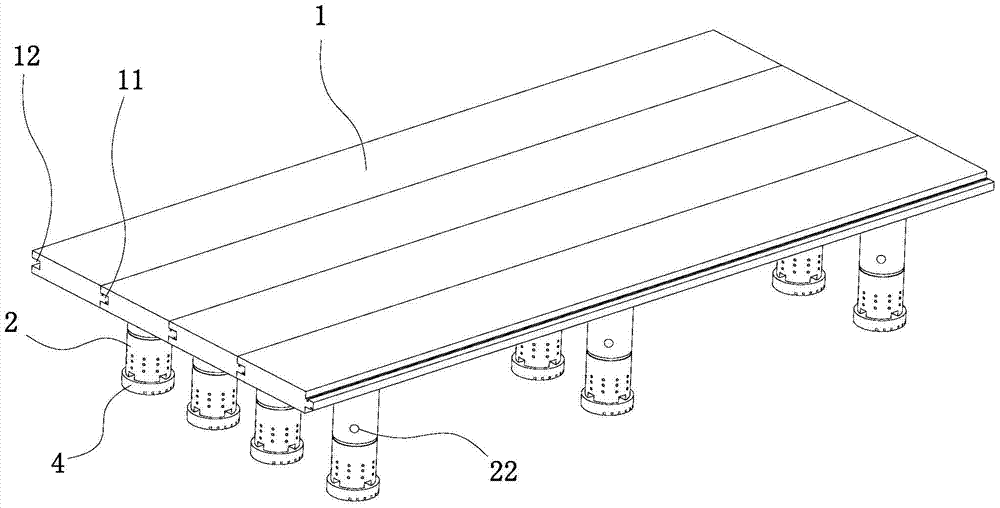

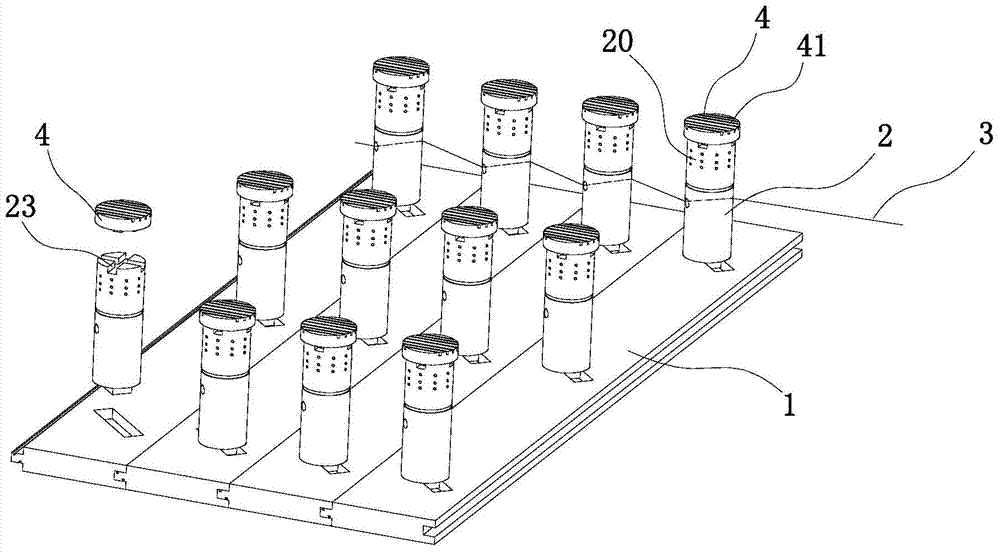

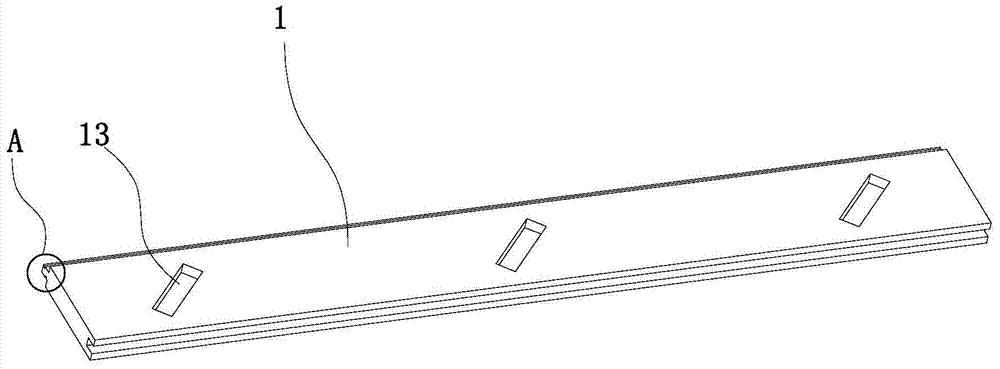

[0028] Such as figure 1 As shown, the keel-free floor of this embodiment includes a floor body 1. The floor body 1 has protruding strips 11 and grooves 12 on both lateral sides, and adjacent floor bodies 1 pass through protruding strips 11 and grooves 12 The matching installation also includes a supporting column 2 supporting and installing below the floor body 1. The upper end of the supporting column 2 is provided with a protrusion 21 matingly connected with the mounting groove 13 on the lower surface of the floor body 1, and the supporting column 2 has a radial passage. The lower end of the hole 22 is screwed with a column 20, the central cavity of the column 20 is placed with an insect repellent, and the side wall of the column 20 is provided with a vent 201. The uprights 20 are evenly distributed under the floor, so that the insect repellent is uniformly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com