An automatic door lock assembly device

An automatic door lock and assembly technology, applied in the direction of building locks, buildings, building structures, etc., to achieve the effect of increasing service life, simple structure and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

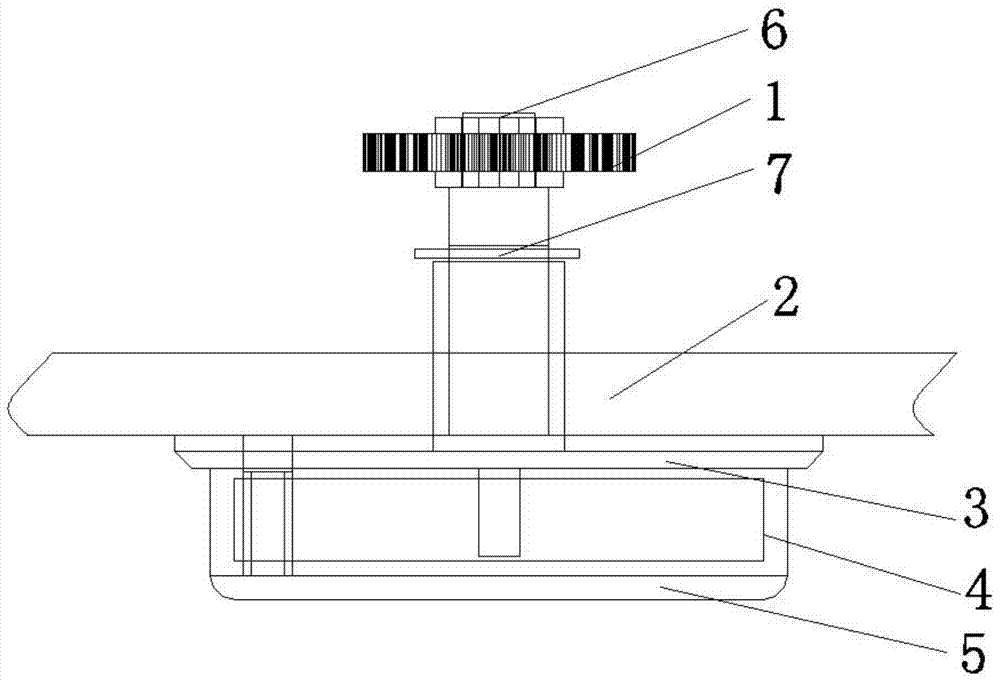

Embodiment 1

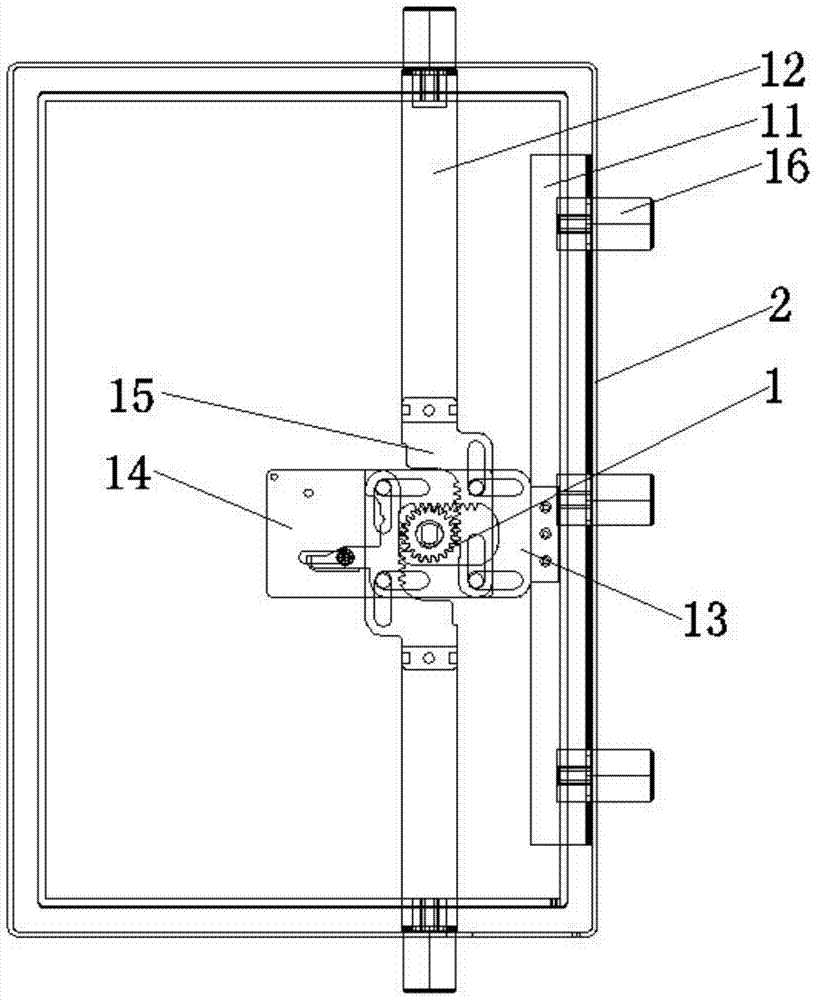

[0039] As the above-mentioned automatic locking door assembly device, the difference of this embodiment is that, refer to image 3 As shown, it is the overall structure diagram of Embodiment 1 of the automatic door lock assembly device of the present invention; the assembly device also includes a lock bolt guide plate 11, two bolt head frames 12, and a first transverse latch plate 13. A second horizontal latch plate 14, two longitudinal latch plates 15 and a plurality of bolt heads 16, wherein the lock bolt guide plate 11 is connected with the door panel 2 for laterally guiding the bolt heads The bolt head frame 12 is respectively located on the upper and lower sides of the door panel 2, one end of the bolt head frame 12 is connected with the door panel 2, and the other end is connected with an end of the longitudinal latch plate 15, the bolt The head frame 12 is used for the longitudinal guidance of the bolt head; the other end of the longitudinal latch plate 15 is engaged wi...

Embodiment 2

[0046] As the above-mentioned automatic locking door assembly device, the difference of this embodiment is that, refer to Figure 9 As shown, it is a partial front view of Embodiment 2 in the automatic locking door assembly device of the present invention; Figure 10 As shown, it is a partial top view of Embodiment 2 of the automatic locking door assembly device of the present invention; the assembly device also includes a lock bolt control piece 17, and the main body of the lock bolt control piece 17 is a strip-shaped plate structure, One end is a fixed end 171, which is connected with the door panel 2 in a specific application to obtain the effect of fixing one end; the other end is an operating end 172, which is used to limit and release the limit bolt head 16 from extending out of the outer frame in a specific application Perform locking action.

[0047] When the safe door lock needs to be opened, the bolt head frame 12 and the bolt head 16 are retracted, and the safe doo...

Embodiment 3

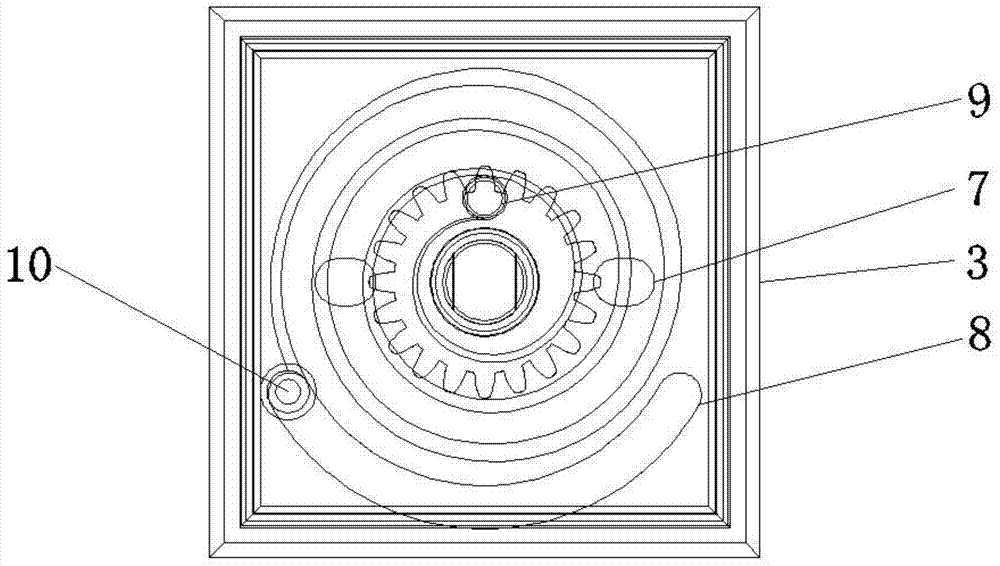

[0051] As the above-mentioned automatic locking door assembly device, the difference of this embodiment is that the overall structure of the first embodiment is combined with the lock bolt control piece 17 in the second embodiment, refer to Figure 11 As shown, it is the overall structure diagram of the third embodiment of the automatic door lock assembly device of the present invention. When unlocking, insert the key, twist the handle 5, and make the coil spring 4 generate torque, and make the The coil spring positioning column 10 of the second handle seat moves in the chute 8, and at the same time, the rotation of the handle 5 passes through the mandrel 6, driving the rotation of the mechanism gear 1, so that the first transverse lock The latch plate 13, the second transverse latch plate 14 and the longitudinal latch plate 15 all move towards each other, and drive the horizontal bolt head and the longitudinal bolt head to shrink inwardly, thereby opening the safe door, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com