Hydraulic amplifying type ultrahigh-pressure fuel supply device

A technology of fuel supply and hydraulic amplification, which is applied in the direction of fuel injection device, measuring device, charging system, etc. It can solve the problems of low fuel supply efficiency of fuel supply device, difficulty in increasing fuel injection pressure, and easy overheating of fuel, so as to improve the fuel supply. Oil efficiency and waste reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

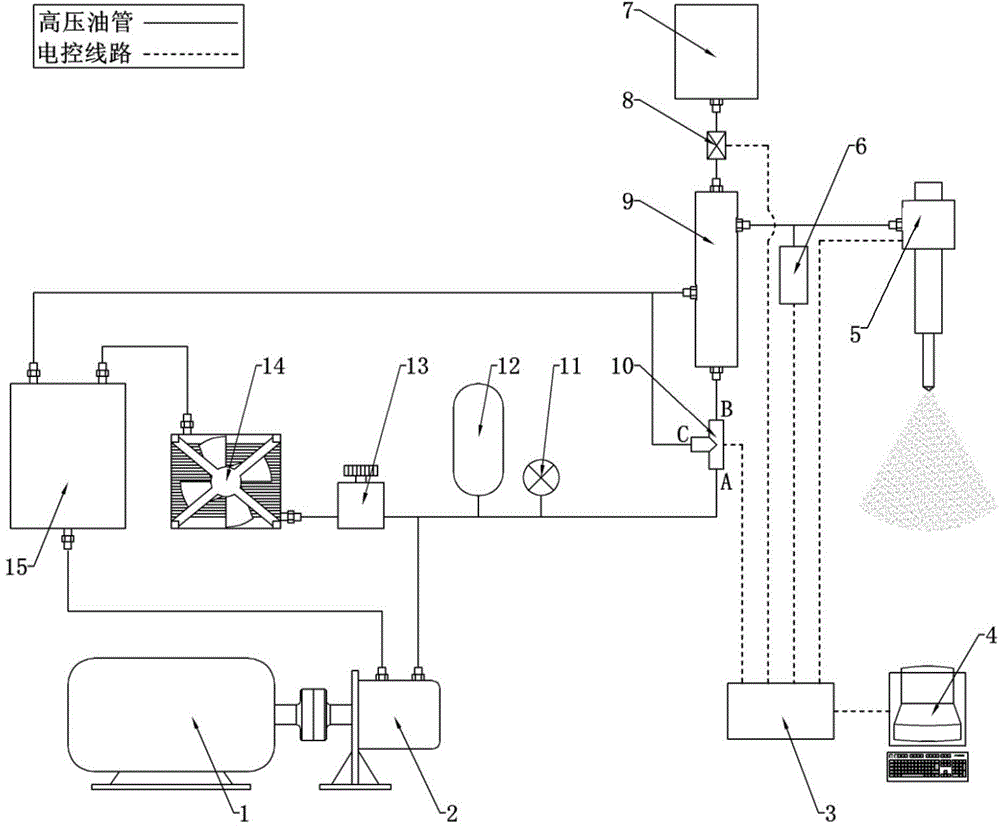

[0026] The present invention is a hydraulic amplification type ultra-high pressure fuel supply device, such as figure 1 As shown, it includes a hydraulic oil pump 2, a hydraulic oil tank 15, a pressure regulating valve 13, a fuel oil tank 7, an electronically controlled valve 8, a pressure amplification chamber 9, an electronically controlled three-way valve 10 and a controller 3,

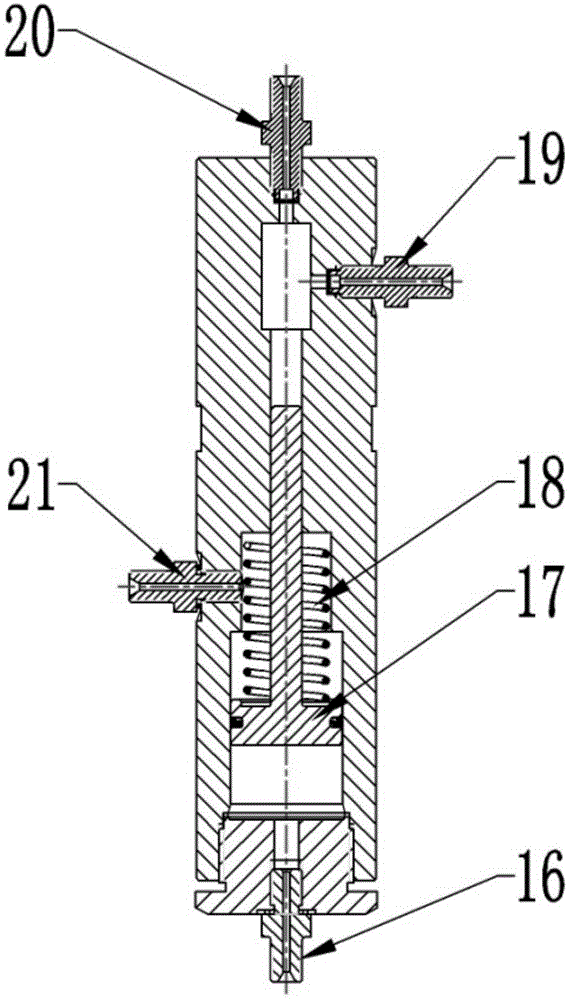

[0027] like figure 2 As shown, there is a T-shaped piston 17 in the pressure amplification chamber 9, the upper part is the small piston head, and the lower part is the large piston head; The side of the small head of the piston can form several times the liquid pressure on the side of the large head of the piston; the side wall surfaces at both ends of the piston 17 are in contact with the inner wall surfaces of the T-shaped cavity in the pressure amplificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com