Double-screw high-pressure surplus energy recycling device

A residual energy recovery, twin-screw technology, applied in the field of machinery, can solve problems such as energy cannot be fully utilized, and achieve the effect of light weight, convenient operation and maintenance, and small flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

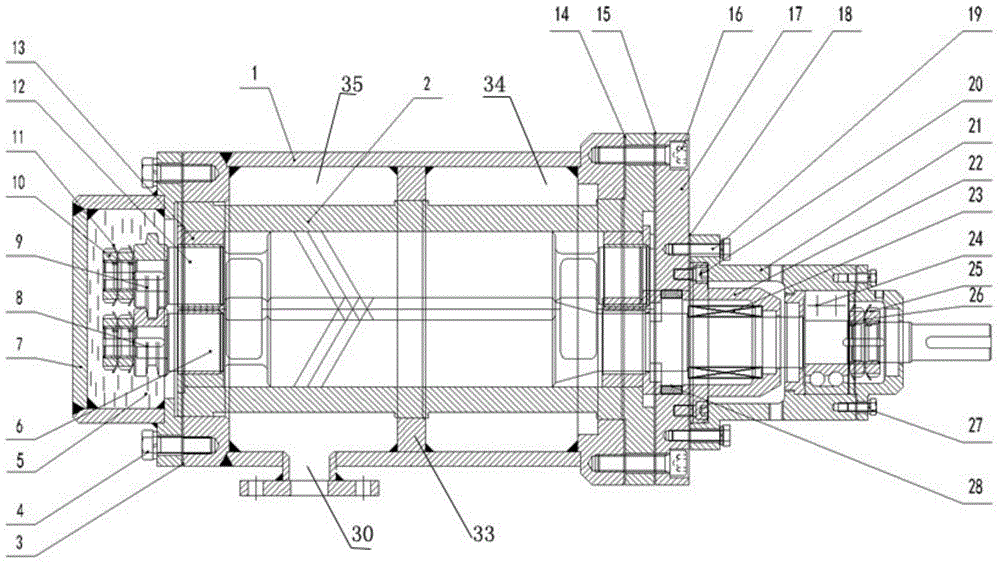

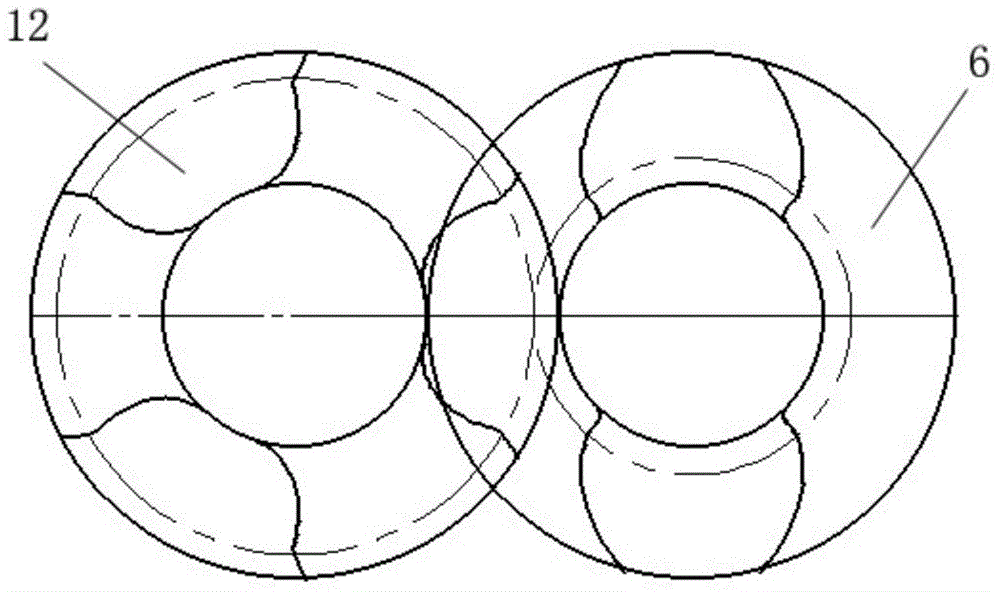

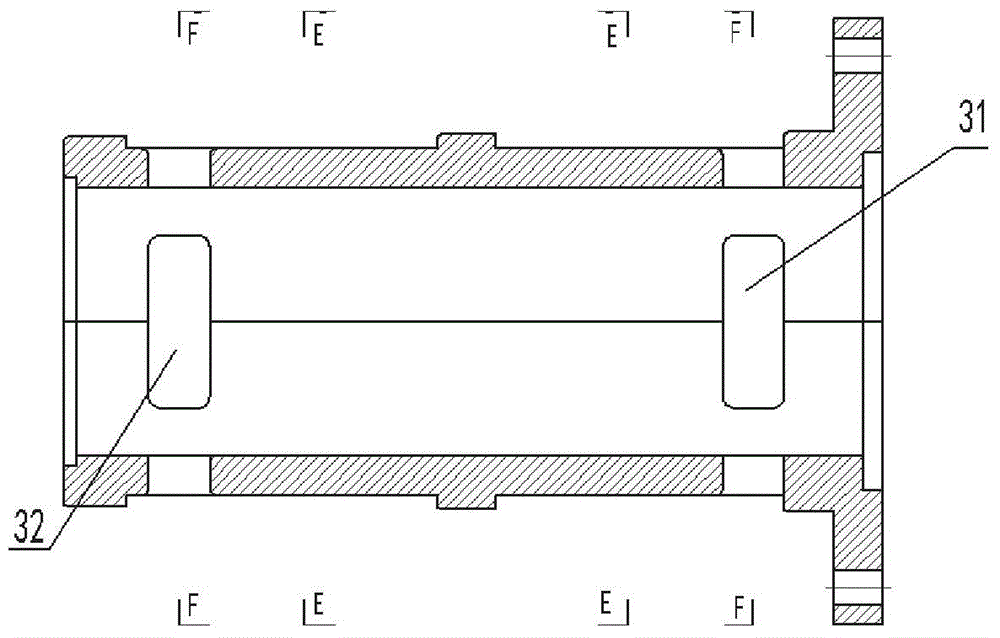

[0040] figure 1 It is an overall top sectional view of a twin-screw high-pressure residual energy recovery device according to the present invention. A double-screw high-pressure residual energy recovery device, including the core components of the driving screw 6, the driven screw 12, the main components of the device include a bushing 2, the device shell 1, the front end cover 17, the rear end cover 7, the driving friction wheel 8 and the slave Dynamic friction wheel 9, bearing seat 21, machine cover 22. The first gasket 3 is interposed between the rear end cover 7 and the device housing 1 and fastened by bolts 4 . A second gasket 14 and a third gasket 15 are also sandwiched between the bushing 2 , the device housing 1 and the front end cover 17 and fastened by bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com