Novel output shaft clutch type gearbox

A technology for output shafts and clutches, which is applied to vehicle gearboxes, instruments, transportation and packaging, etc. It can solve problems such as high driving technical requirements, difficulty in shifting gears, and complex structure of gearboxes, so as to improve service life and operation Reliability, improve the smoothness of operation, and realize the effect of shifting gears on the move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

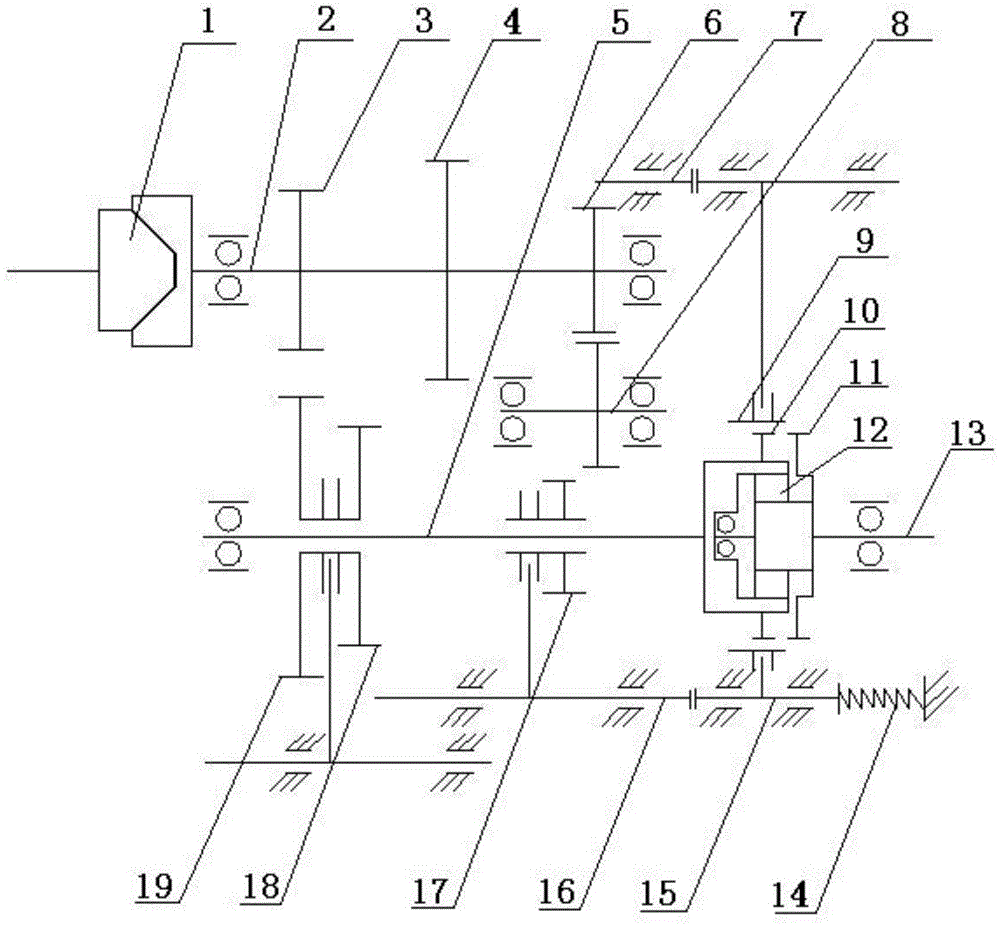

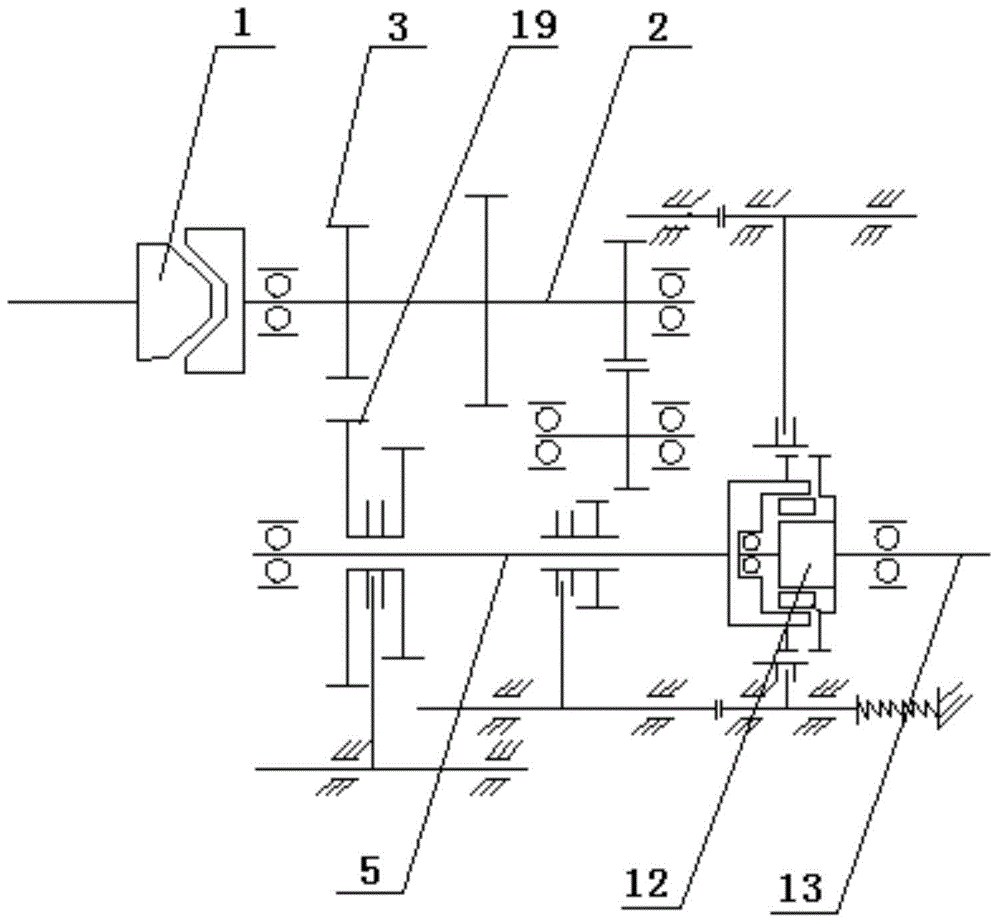

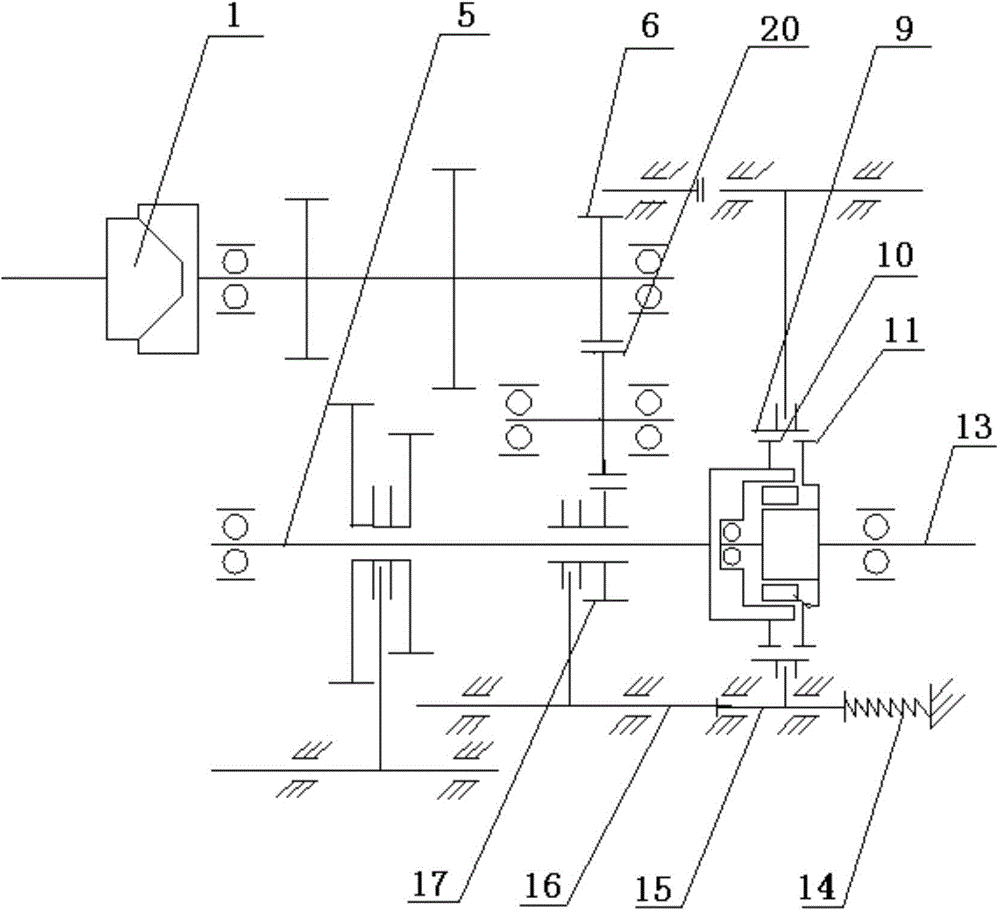

[0021] A new type of output shaft clutch type gearbox, including input shaft clutch 1, input shaft 2, input shaft first driving gear 3, input shaft second driving gear 4, input shaft reverse gear driving gear 6, intermediate shaft 8, mounted on Reverse gear intermediate gear 20, output shaft, output shaft sliding gear set and reverse gear sliding gear 17 on the intermediate shaft. The output shaft sliding gear set is composed of the output shaft first sliding gear 19 and the output shaft second sliding Gear 18 constitutes.

[0022] An input shaft clutch is installed on the input shaft, which is used to combine or cut off the engine power. On the input shaft, the first driving gear of the input shaft, the second driving gear of the input shaft and the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com