Train for quick sealing of pipeline

A pipeline and fast technology, applied in the direction of special pipes, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of high cost of pipeline maintenance and repair, performance that cannot meet the requirements, long manpower and financial resources, etc., to solve the problem of pipeline sealing Difficult to block, good automatic control performance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

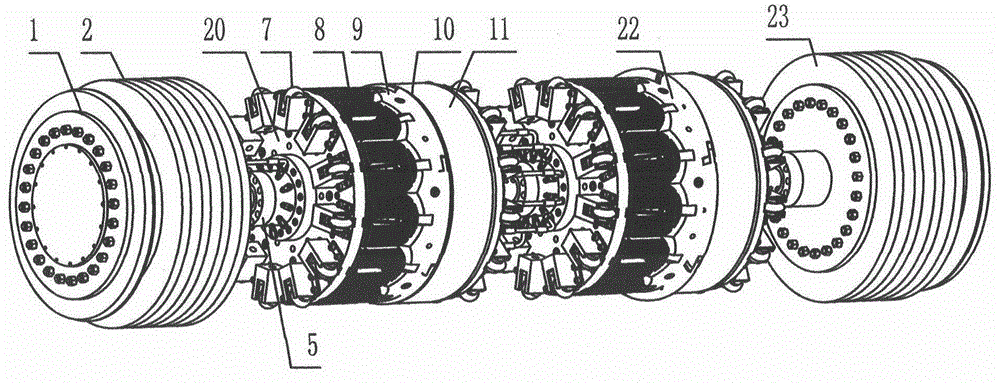

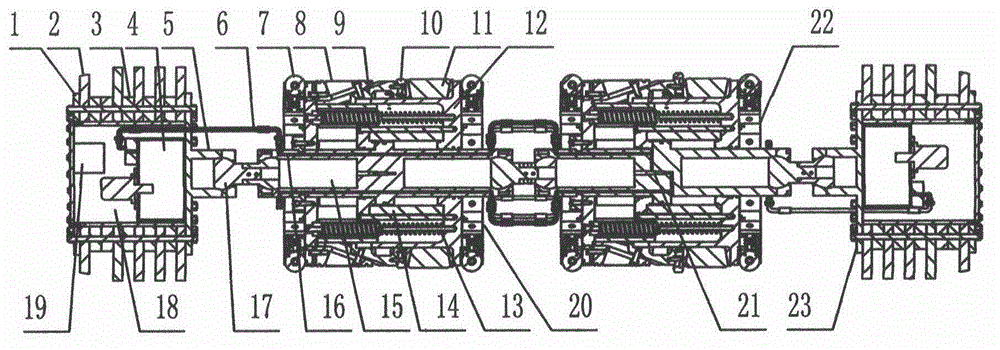

[0024]Below in conjunction with accompanying drawing and embodiment the present invention will be further described: embodiment: referring to accompanying drawing, pipeline fast plugging train, it is characterized in that: be provided with at least front and back two pipe pigs 1,23 and two plugging devices 20 , 22, the pig is arranged on each of the front and rear sides of the occluder, and a connection assembly 5 and a power transmission part 6 are arranged between the two; the pig is provided with a cylindrical cavity Body 18, the cavity is provided with a cylinder wall, the front is provided with a gland, and the rear is provided with a chassis, the cavity is provided with a power device 4 for powering the occluder, and the outer periphery of the cylinder wall is provided with sealing assemblies 2 and 3; An axial guide rod 15 is arranged in the middle of the occluder, and the outer periphery of the guide rod is provided with a moving part 12. The front end of the outer perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com