Modified master batch manufacturing equipment of biodegradable domestic flowerpot and biodegradable water basin and manufacturing method thereof

A technology for modifying masterbatch and manufacturing equipment, which is applied in the field of biomanufacturing, which can solve the problems of inability to cool uniformly and poor cooling molding effect, and achieve the effect of saving space, clear division of labor in device settings, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

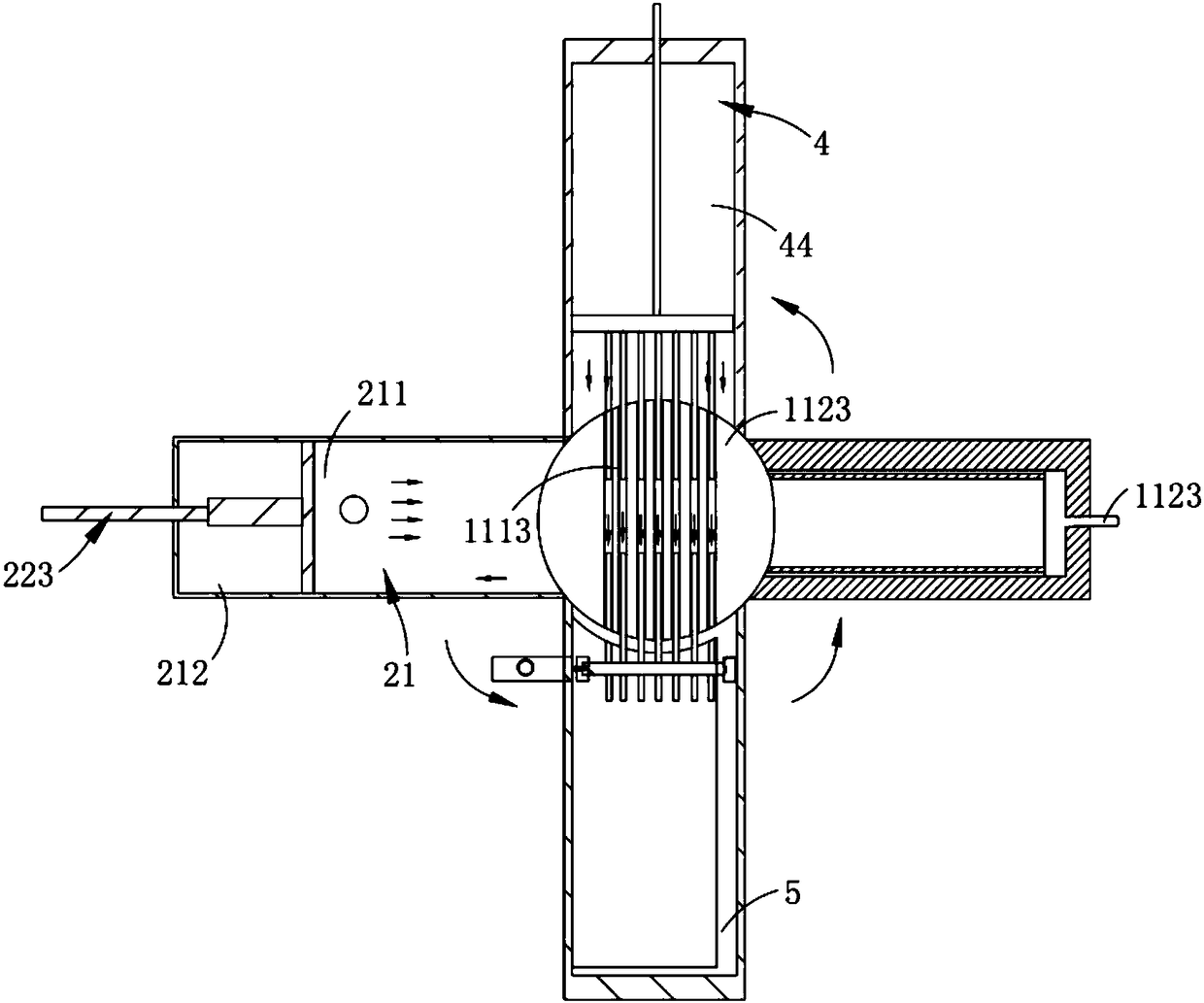

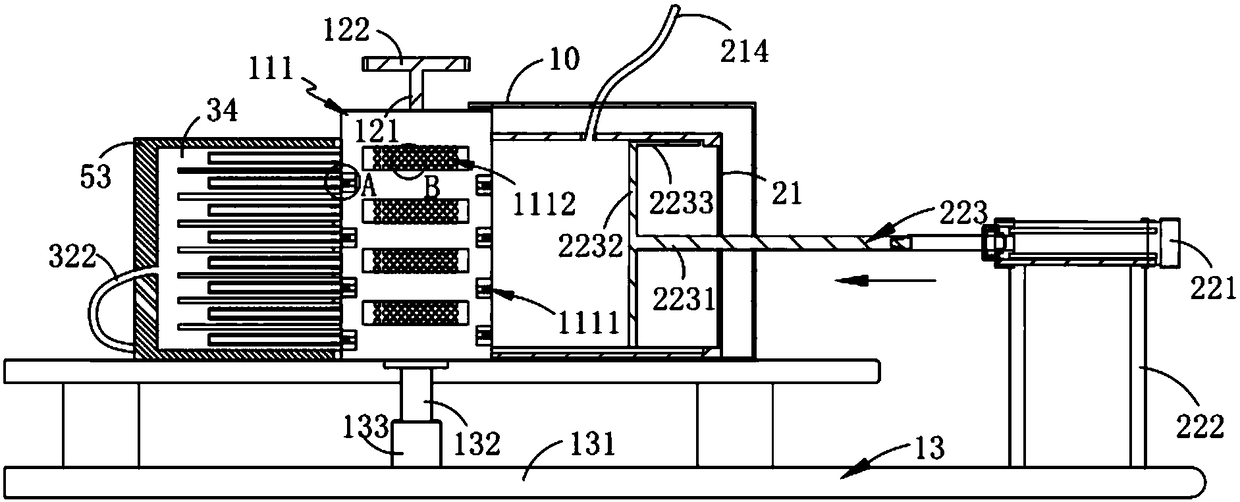

[0075] Such as figure 1 , Figure 12 As shown, the modified masterbatch manufacturing equipment and manufacturing method of degradable household flower pots and water receiving basins include:

[0076] Melting material device 1, said melting material device 1 comprises a melting material mechanism 11 for forming a bar-shaped material, a control mechanism 12 arranged on said melting material mechanism 11, a cooling device sleeved outside said melting material mechanism 11 The mechanism 31 and the ventilating mechanism 32 matched and arranged outside the cooling mechanism 31; the melting material unit 111 is arranged on the melting material mechanism 11;

[0077] The melting material unit 111 includes a melting material piece a1111 penetratingly arranged along the transverse direction of the melting material mechanism 11 , penetratingly arranged along the longitudinal direction of the melting material mechanism 11 and intersecting and perpendicular to the melting material piece...

Embodiment 2

[0124] Such as Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

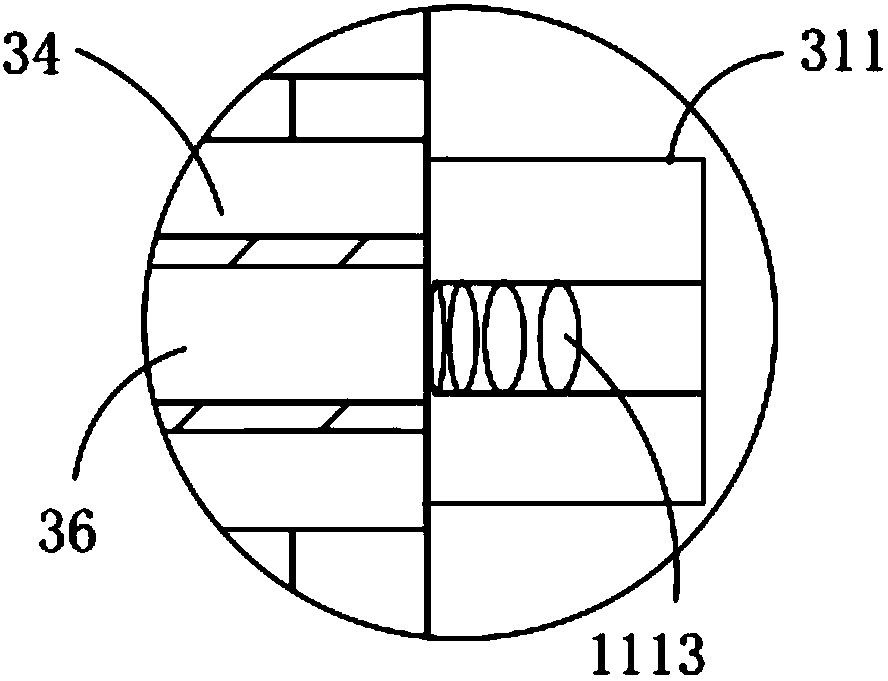

[0125] further, such as Figure 8 As shown, the melt unit 111 includes:

[0126] A molded part a1111, the molded part a1111 is arranged through the lateral direction of the melting material mechanism 11;

[0127] The forming part b1112, the forming part b1112 is arranged through the longitudinal direction of the melting material mechanism 11 and interlaced with the forming part a1111 and vertically arranged; and

[0128] A connecting rod 1114, the connecting rod 1114 is used to fix the forming part a1111 and the forming part b1112 in the cooling device 3;

[0129] Both the molded part a1111 and the molded part b1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com