Multi-point-location nitrogen oxide continuous monitoring device and continuous monitoring method for SCR reactors

A nitrogen oxide and monitoring device technology, applied in the field of flue gas denitrification, can solve the problems that it is difficult to accurately reflect the overall uniform distribution performance of the SCR reactor, and there is no continuous monitoring device for the SCR inlet, so as to improve the monitoring accuracy and avoid material pollution. Consumption, the effect of ensuring equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

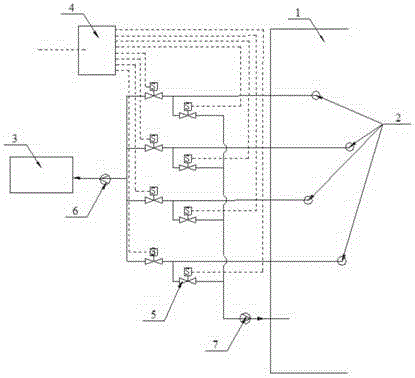

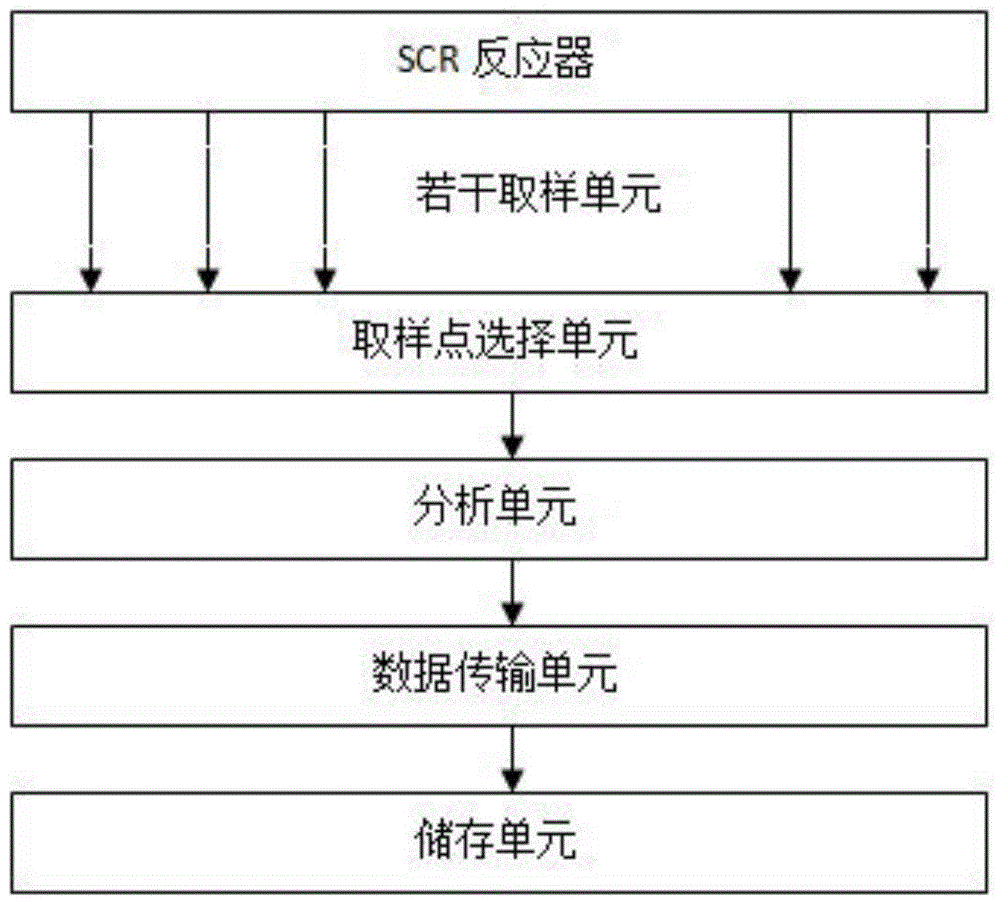

[0035] For the structure and working principle of the multi-point nitrogen oxide continuous monitoring device of the SCR system of this embodiment, please refer to figure 1 with figure 2 . The multi-point nitrogen oxide continuous monitoring device of the SCR system includes a plurality of sample continuous sampling units 2 for sampling the flue gas in the outlet flue 1 of the SCR reactor. Wherein, it is preferable to distribute the sampling points of the continuous sampling unit 2 according to the requirement and according to the arrangement principle of the grid testing method. The specific number of sampling points is determined according to different engineering needs. In actual engineering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com