Shred drier cylinder wall temperature prediction model based on cut tobacco shred moisture content

A technology of moisture content and silk drying machine, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems such as the inability to accurately predict the temperature of the cylinder wall, and achieve the effect of increasing the steady state time and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

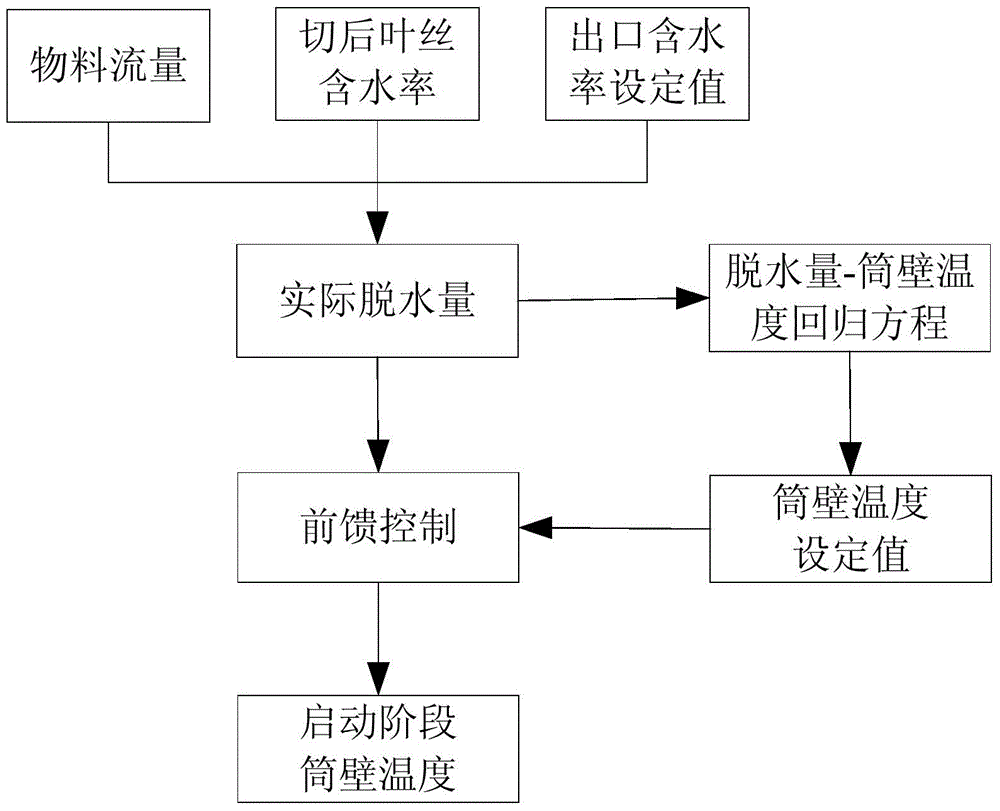

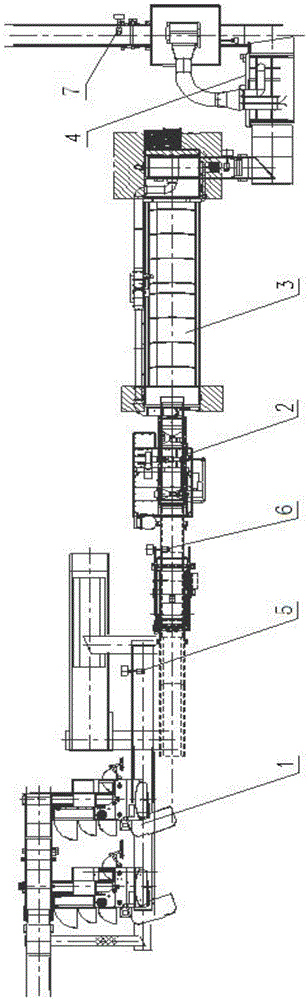

[0019] refer to figure 1 As shown, a prediction model for the cylinder wall temperature of the shredded shreds based on the moisture content of the shredded leaves, the shredded tobacco used is the brand of Yunyan (soft treasure), including the following steps:

[0020] 1. The water content of shredded shredded leaves was collected for 5 minutes in the drying process of shredded leaves, and the average value of W1 was 20.673%;

[0021] 2. According to the process technology standard SPW4 set value of 12.7%, calculate △F according to formula 2 W 824.9187l / h;

[0022] 3. According to the process technology standard, the set value of P is -30ubar, and T is calculated according to formula 3 SP 143.76°C;

[0023] 4. The operator will T SP After the value is entered into the formula list, the feedforward control of the wire dryer calculates the cylinder wall temperature T pv It is 144.0°C; the average value of cylinder wall temperature is 144.1°C and the difference is 0.1°C in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com