Paper tube detection machine

A detection machine and paper tube technology, which is used in sorting and other directions to improve the efficiency of detection and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

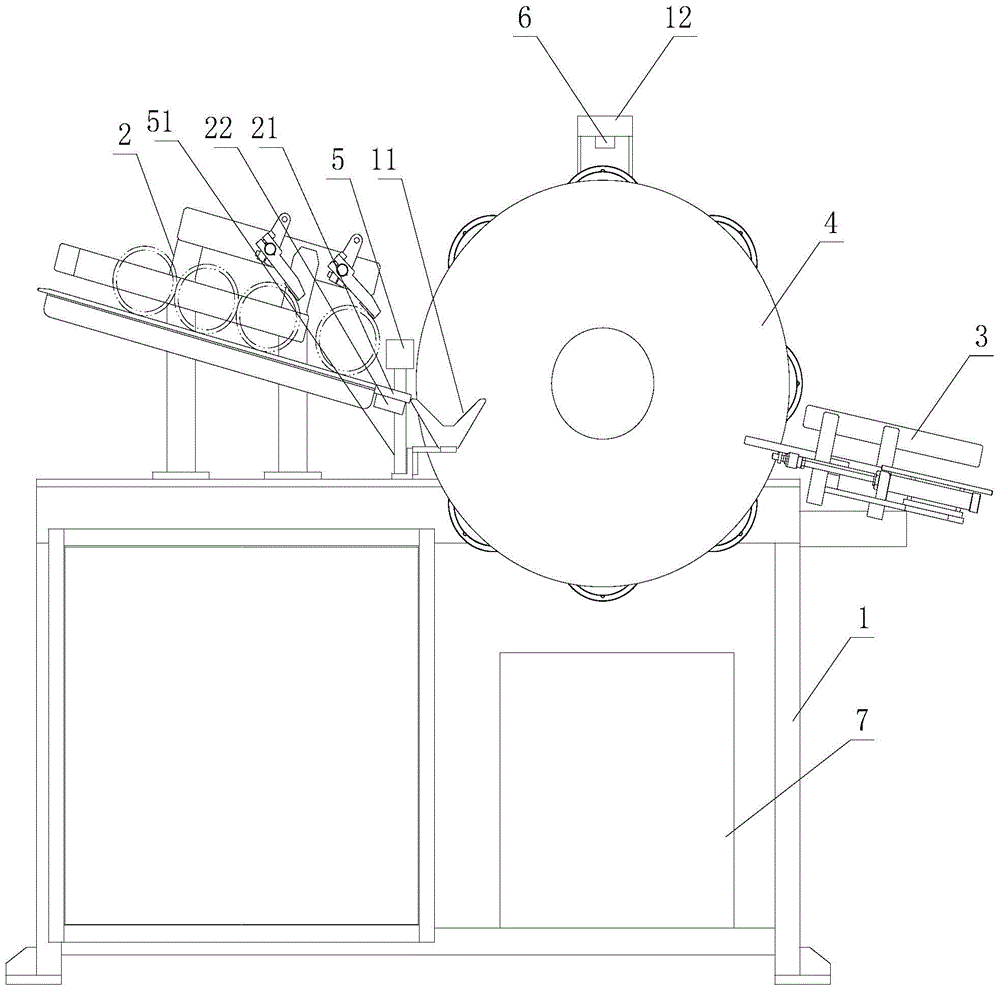

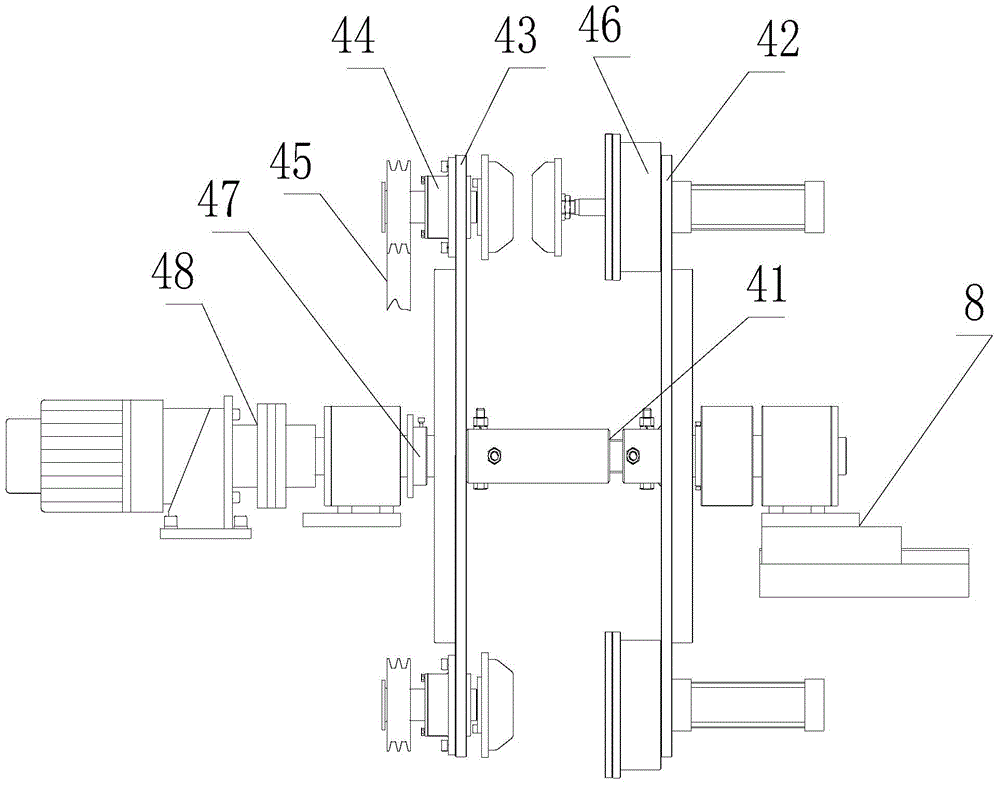

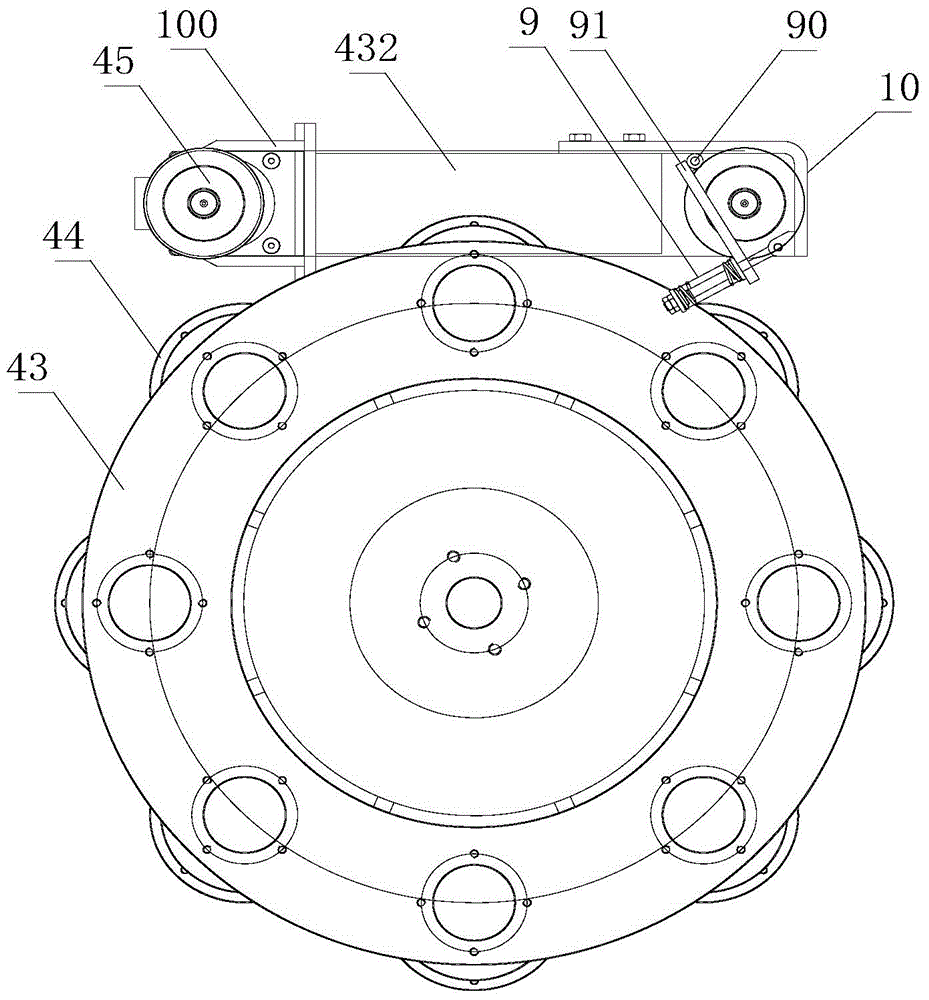

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9As shown, a paper tube detection machine includes a frame 1, a feed device 2 arranged at the front end of the frame 1 and a discharge device 3 arranged at the tail end of the frame 1, and the discharge device 3 is provided with three To facilitate the outlet of the paper tube discharge, a control assembly 4 for controlling the rotation of the paper tube is provided on the frame 1 between the feed device 2 and the discharge device 3, and on the frame 1 above the control assembly 4 Be provided with the first video camera 6 that is convenient to photograph paper tube surface, be provided with the second video camera 5 that is convenient to photograph paper tube two end faces on the frame 1 of feeding device 2 outlets, described frame 1 is provided with for Judging the PC machine 7 of the quality of the paper tube, the first camera 6 and the second camera 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com