Edge-cutting processing mould for cold pier ultra-short rod product

A technology for processing molds and ultra-short rods, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of small application range, inability to transfer, and inability to realize edge trimming technology, etc., to achieve simple structure, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

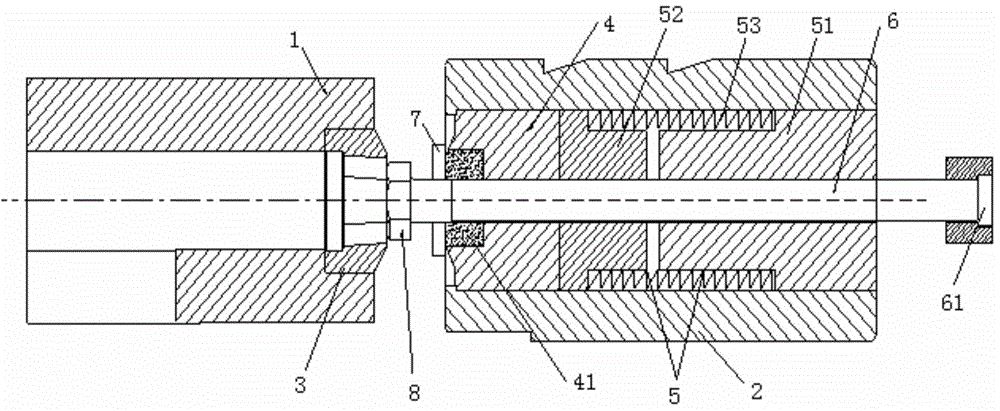

[0012] Refer to figure 1 , The present invention is a cold heading ultra-short rod product trimming processing mold, including a front mold body 1, a rear mold body 2, a trimming die 3, a trimming top mold 4, a floating mechanism 5 and a top rod 6. The front mold A trimming die 3 is embedded in the rear end of the body 1, and the rear die body 2 is provided with a trimming top die 4 and a floating mechanism 5, and the trimming top die 4 is set in front of the floating mechanism 5. The side top mold 4 and the floating mechanism 5 are provided with an ejector rod 6 capable of ejecting the stamped parts from the cavity 41 of the trimming top mold 4. The floating mechanism 5 includes a fixed body 51, a floating body 52 and a spring 53. A floating body 52 is provided in front of the fixed body 51. The fixed body 51 and the floating body 52 are supported and connected by a spring 53. The front end surface of the floating body 52 is attached to the rear end surface of the trimming top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com