Cam indexer bearing heavy load

A cam divider, heavy-duty technology, used in metal processing mechanical parts, precision positioning equipment, metal processing equipment, etc., can solve the problems of the divider stuck, can not meet the requirements of use, etc., achieve the increase of axial force and partial gravity , to meet the needs of use, to increase the effect of the bearing radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

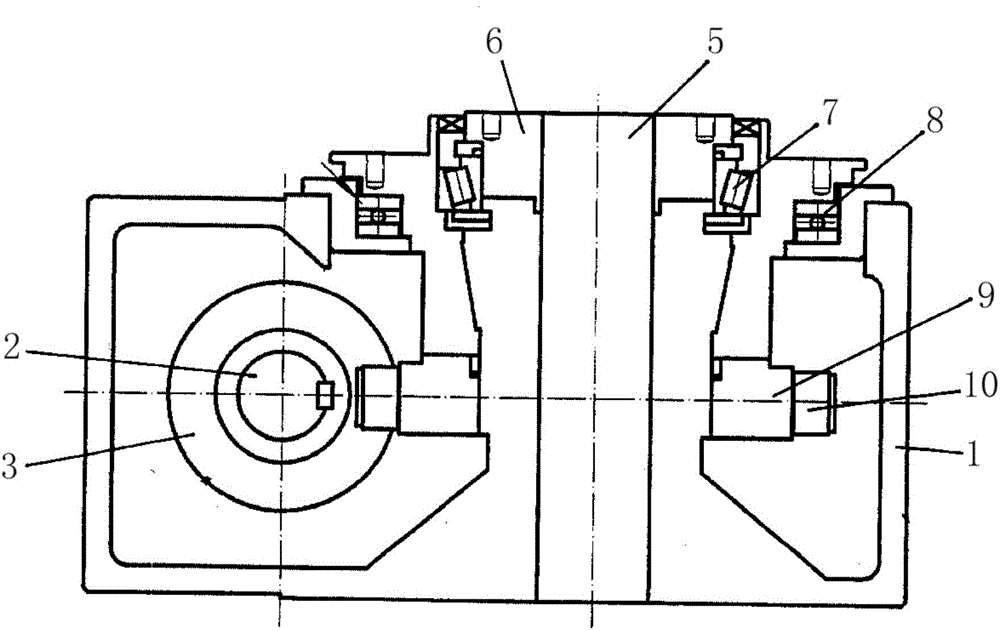

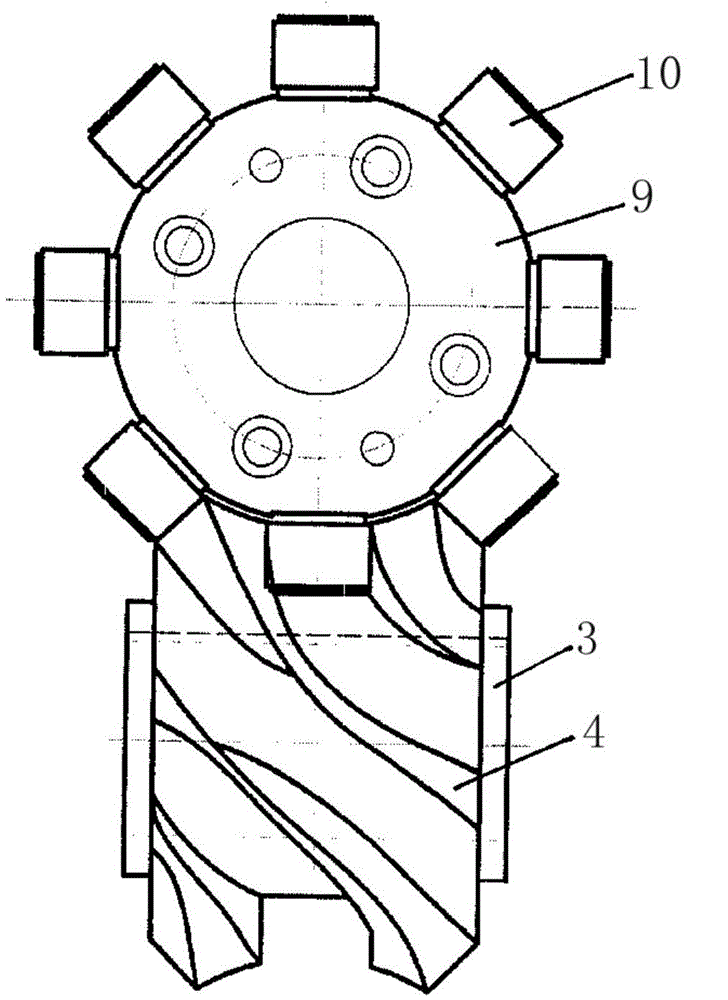

[0010] Such as figure 1 , 2 As shown, in the present invention, a cam 3 is laterally supported by the input shaft 2 on the inner side of the box body 1, and a plurality of spiral convex strips 4 are evenly distributed on the circumferential surface of the cam body 3, and the output shaft 5 is longitudinally supported on the side of the box body 1. On the other side of the interior, the upper part of the output shaft 5 is connected to the box body 1 through a gland 6, a tapered roller bearing 7 is arranged between the output shaft 5 and the gland 6, and a Thrust cylindrical roller bearings 8 are arranged between the casings 1, the turret 9 is arranged in the middle of the output shaft 5, and a plurality of dials 10 are all arranged on the outer periphery of the turret 9, and the dials 10 on the turret 9 Cooperate with the gap of the spiral convex strip 4 on the cam 3 to realize the intermittent rotation of the output shaft 5 driven by the cam 3 .

[0011] Through the above se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com