Detection system and method for sawing surface verticality and saw blade teeth

A detection system, sawing surface technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc. and other problems, to prevent excessive offset, improve processing quality, and reduce processing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

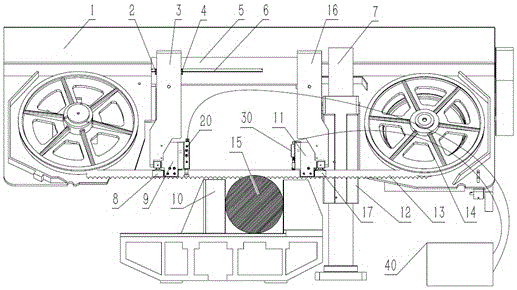

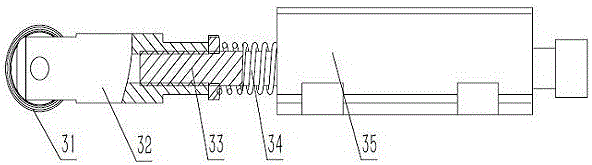

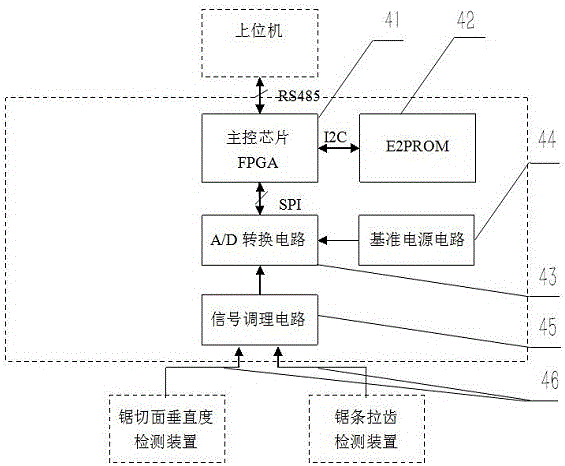

[0043] Such as figure 1 As shown, the detection system for the verticality of the sawing surface and the toothing of the saw blade is composed of a detection device 20 for the verticality of the sawing surface, a detection device 30 for the toothing of the saw blade, and a detection signal processing device 40; 1 position detection sensor 2, movable guide arm 3, second position detection sensor 4, dovetail beam 5, guide arm position detection scale 6, guide column 7, movable end guide roller 8, movable guide seat 9, movable clamp 10, Fixed guide seat 11, guide column cover 12, saw blade 13, saw wheel 14, workpiece to be sawed 15, fixed guide arm 16, fixed end guide roller 17;

[0044] The verticality detection device 20 of the sawing surface and the tooth detection device 30 of the saw blade are installed on the movable guide seat 9 and the fixed guide seat 11 respectively; After the seat 11 is guided and twisted, the saw blade 13 is perpendicular to the workpiece 15 to be sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com