a ball valve

A technology for ball valves and valve stems, which is applied in the direction of valve devices, cocks including cut-off devices, mechanical equipment, etc., which can solve the problem of poor sealing performance and easy movement of the valve core (the valve stem and other structures will also move together, reducing the life of the sealing structure. and other problems, to achieve reasonable structure, guarantee the sealing effect and service life, and alleviate the effect of incorrect air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

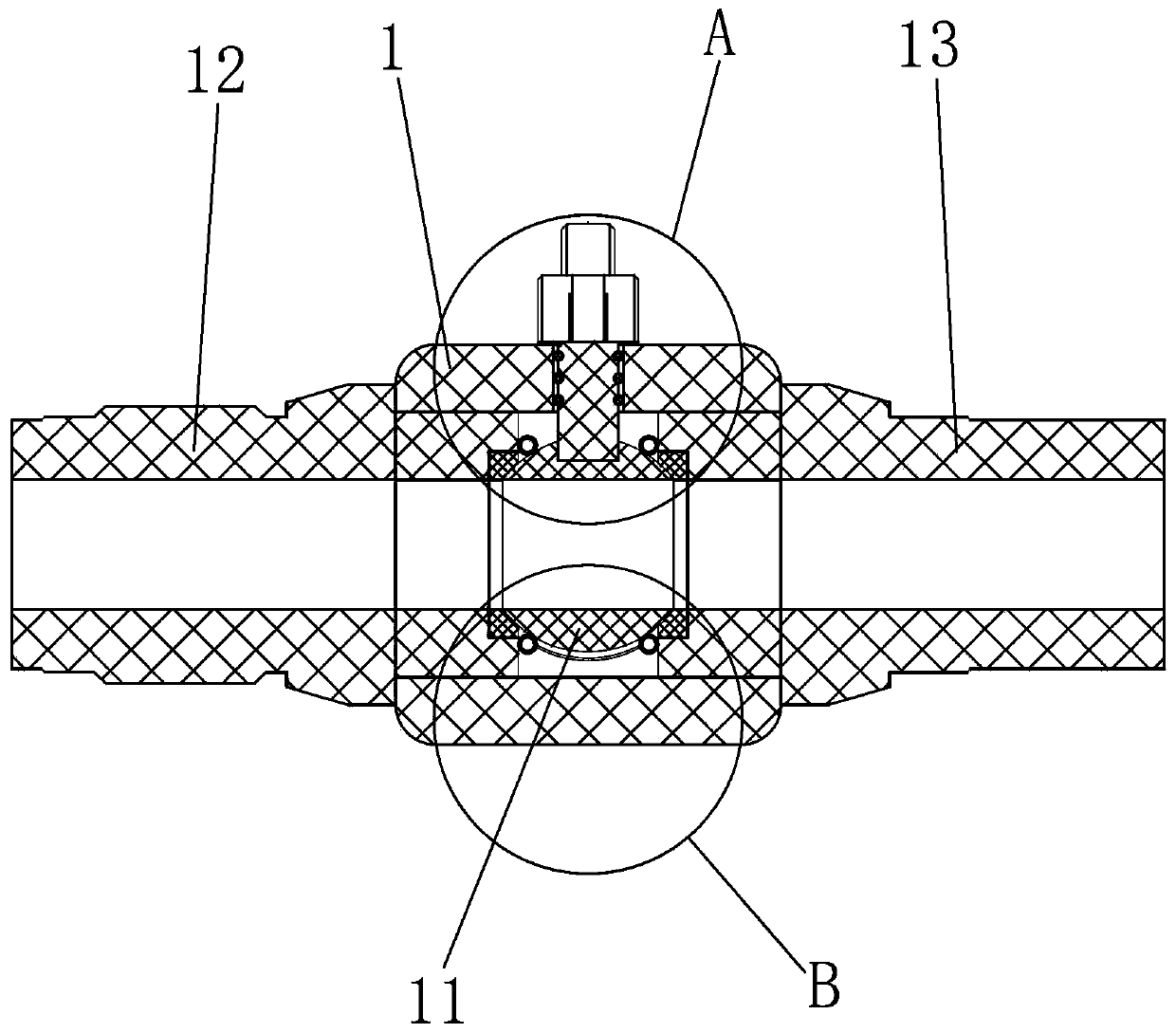

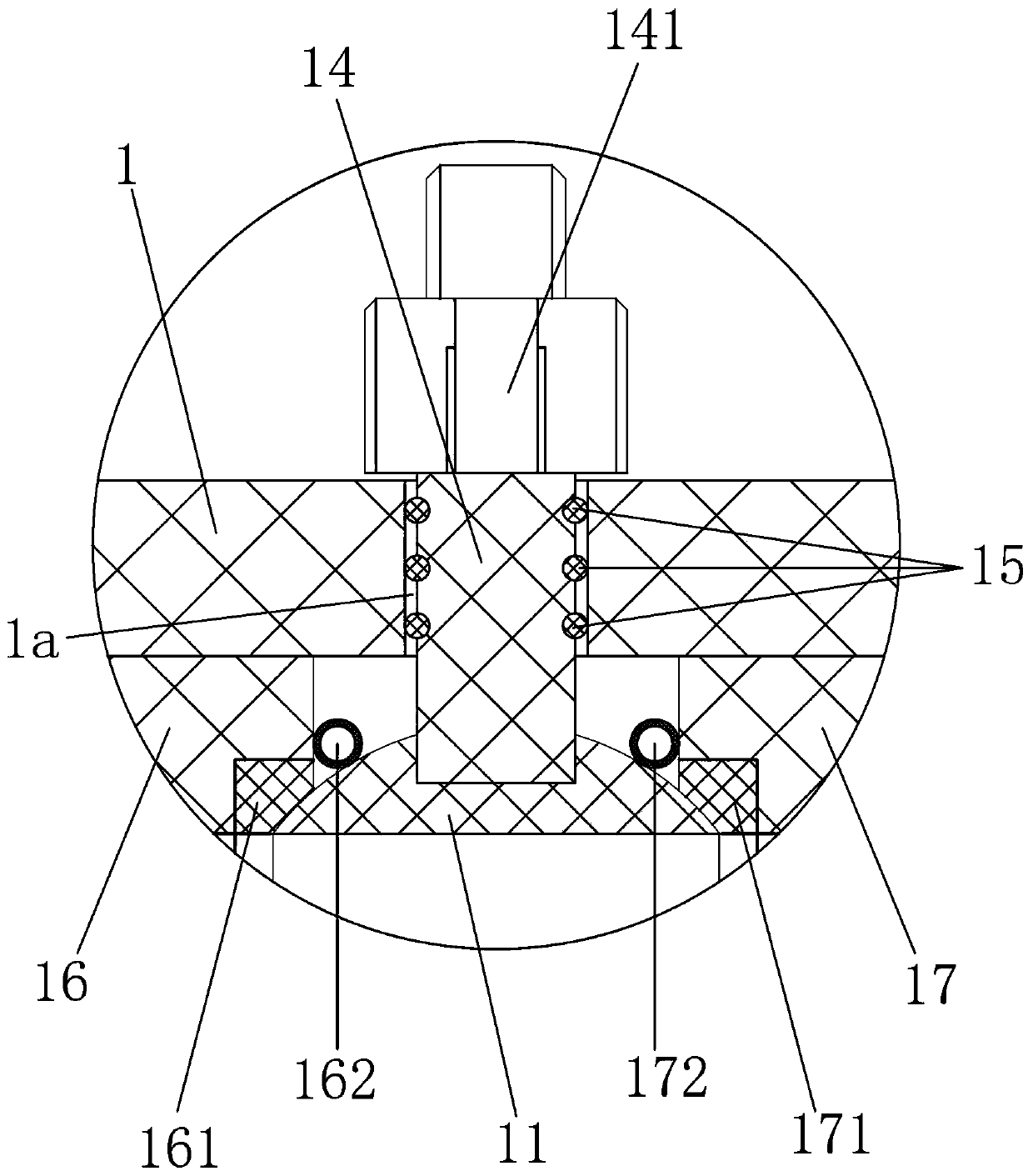

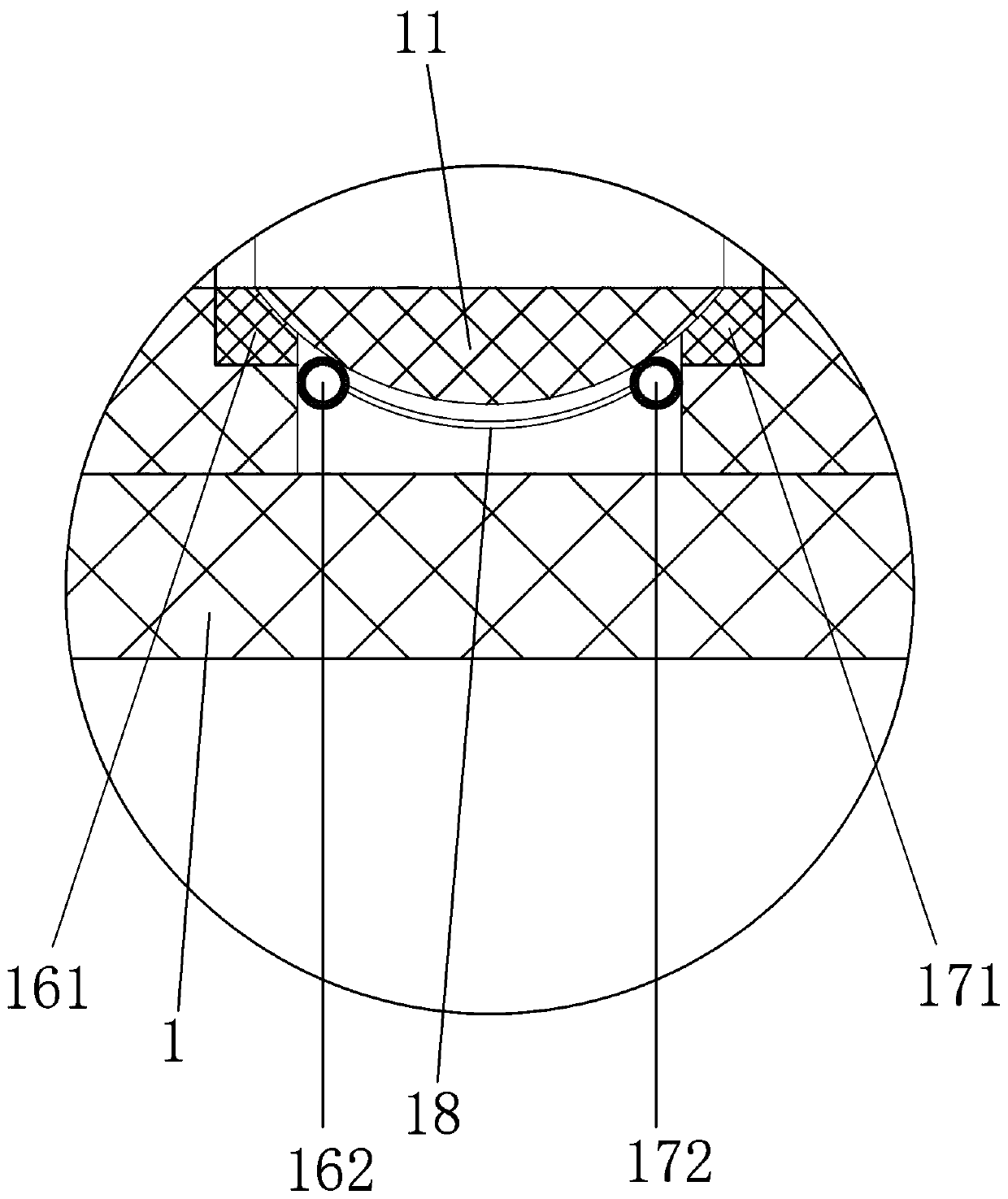

[0027] Embodiment 1: as Figure 1 to Figure 3 as shown,

[0028] Embodiment 1: a kind of ball valve, comprises

[0029] Valve seat 1, valve core 11, left connecting pipe 12, right connecting pipe 13 and valve stem 14 for driving the valve core, the valve seat is provided with a rod hole 1a, the valve stem passes through the rod hole, and the diameter of the rod hole is larger than that of the valve stem Diameter, the valve seat is provided with a channel in the valve, one end of the channel in the valve is connected to the left port, the other end of the channel in the valve is connected to the right port, the seat is provided with a left sealing seat 16 and a right sealing seat 17, and the left sealing seat is provided with There is a valve left sealing ring 161 that is tightly matched with the valve core, and a valve right sealing ring 171 that is tightly matched with the valve core is arranged on the right sealing seat. Between the right connecting pipe and the spool;

...

Embodiment 2

[0038] Embodiment 2: based on embodiment 1, such as Figure 4 to Figure 9 as shown,

[0039] The left connecting pipe is provided with a release structure, and the release structure includes a vertically arranged first release pipe 21, a horizontally arranged release second pipe 22, a vertically arranged release third pipe 23, and a set on the release third pipe. Diffuse valve 231, the bottom of the left connecting pipe is provided with a bottom release hole, the top of the second release pipe is provided with a top release hole 22a, the upper end of the first release pipe is connected to the bottom release hole, the lower end of the first release pipe is connected to the top release hole, and the second release pipe is connected to the top release hole. One end of the tube communicates with the lower end of the third diffuser tube;

[0040]The other end of the second pipe for dispersing is provided with a drawer 3, one end of the drawer is a closed end outside the second pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com