Novel method for measuring drilling and cutting temperature

A cutting temperature and drilling technology, used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as inapplicability, inability to monitor drilling temperature, and inability to directly reach radiation, to avoid random errors , Reliable effect of drilling temperature value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

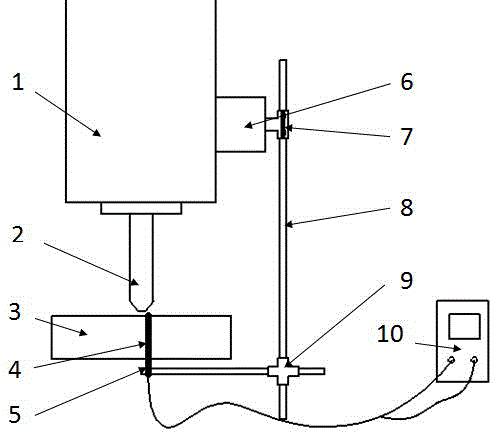

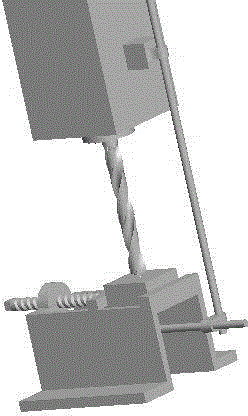

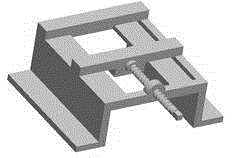

[0016] The invention is a device for continuously changing cutting temperature monitoring in a drilling system. It is based on the principle of artificial thermocouple temperature measurement. By setting the experimental device on the spindle box of a machine tool at one time, it can realize the long-term operation of the entire test piece hole processing cycle. Time and continuous cutting temperature monitoring, specifically using the thermocouple fixing frame device and the drilling temperature measurement fixture, so that the thermocouple moves synchronously with the drill bit along the axial direction at all times, and realizes long-term and continuous cutting temperature collection.

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention is described in detail, present embodiment is based on the premise of technical solution of the invention, has provided detailed implementation method and specific operation process, but protection scop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com