Tracer agent addition device with continuous mixing machine

A mixer and tracer technology, applied in the direction of material electrochemical variables, etc., can solve the problems that affect the development of continuous mixers, the uniformity of continuous mixers cannot be accurately detected, and the performance of continuous mixers cannot be accurately evaluated. Achieve the effects of good uniformity and consistency of addition, accurate control of uniformity and consistency, and little impact on quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

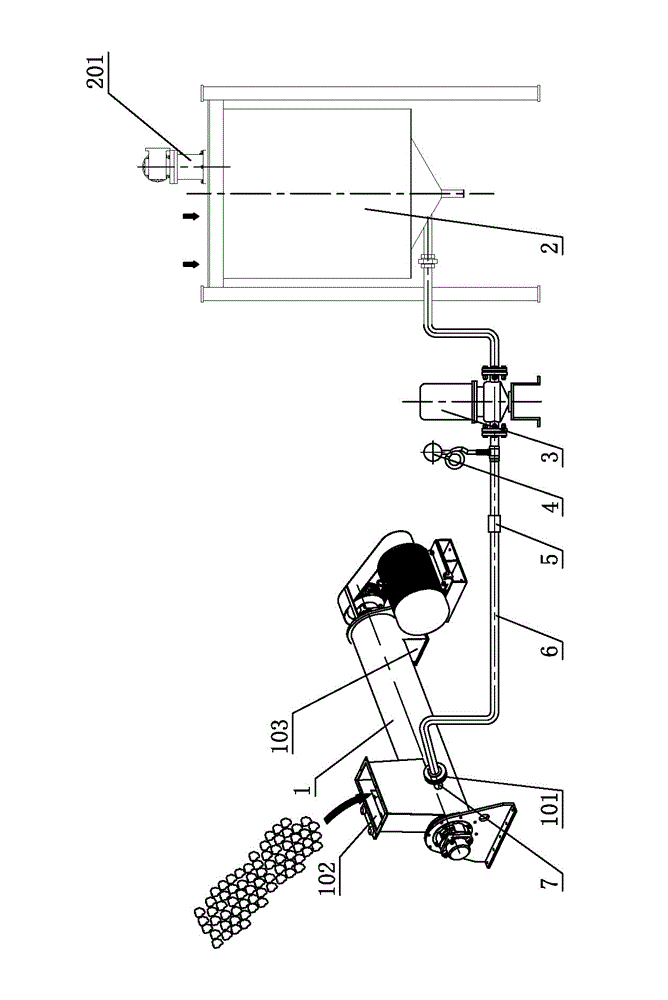

Image

Examples

Embodiment 1

[0024] An existing continuous mixer is used to conduct a mixing uniformity detection test to obtain the performance parameters of the continuous mixer's mixing uniformity. The main motor power of the existing continuous mixer is 30kW (rated current: 57.6A), the rotor diameter is 350mm, the length of the rotor is 2000mm, the rotor speed is 780rpm, the center distance of the inlet and outlet is 1570mm, and the design capacity is 18t / h. The volume of the mixing tank is 1m 3 , Stirring motor power 1.5kW, infusion pump selection function is 2.2KW gear pump CB-B40 (rated flow 40L / min, rated pressure 2.5Mpa). The atomization nozzle is flat atomization nozzle 8015 (the liquid pressure is 0.3Mpa, the amount of addition is 5.9L / min; the liquid pressure is 0.4Mpa, the amount of addition is 6.8L / min), the quantity is 1 piece; the experimental material is corn flour, and the water content is 12.53%. The capacity is 675g / L.

[0025] Turn on the continuous mixer, add materials continuously...

Embodiment 2

[0027]Use another existing continuous mixer to conduct a mixing uniformity detection test to obtain the mixing uniformity performance parameters of this continuous mixer. The main motor of the continuous mixer is 18.5 (rated current: 30.5A), the rotor diameter is 300mm, the length of the rotor is 2000mm, the rotor speed is 870rpm, the center distance of the inlet and outlet is 1260mm, and the design capacity is 12t / h. The volume of the mixing tank is 1m 3 , The power of the agitator motor is 1.5kW, and the infusion pump is a gear pump CB-B40 with a power of 2.2kW (rated flow rate 40L / min, rated pressure 2.5Mpa). The atomization nozzle is flat atomization nozzle 8010 (the liquid pressure is 0.3Mpa, the amount of addition is 3.9L / min; the liquid pressure is 0.4Mpa, the amount of addition is 4.6L / min), the quantity is 1 piece; the experimental material is corn flour, and the water content is 12.53%. The capacity is 654g / L.

[0028] Turn on the continuous mixer, add materials co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com