Three-dimensional printing method and system thereof

A technology of 3D printing and printing direction, applied in the field of 3D printing, can solve the problems affecting the yield rate of 3D printing and achieve the effect of optimizing the effect of 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

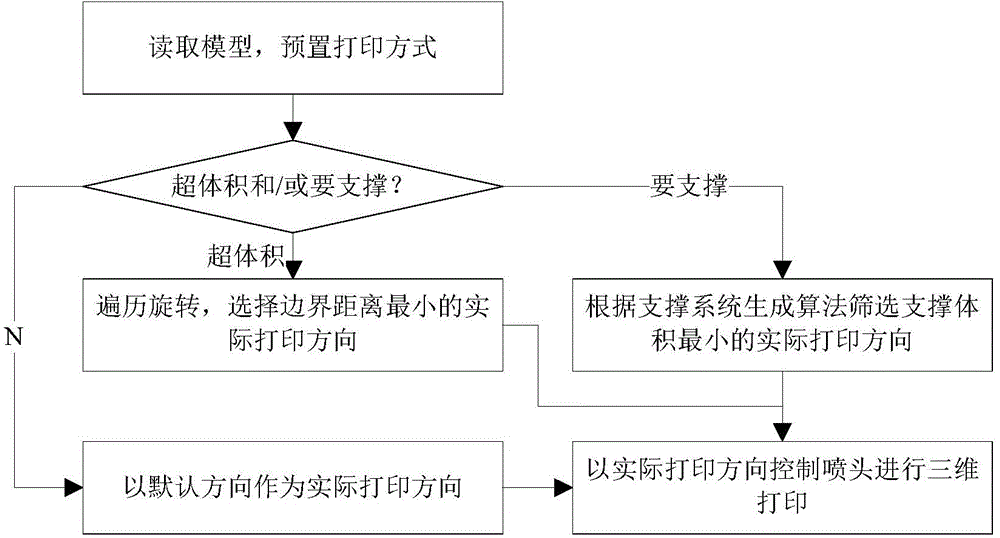

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

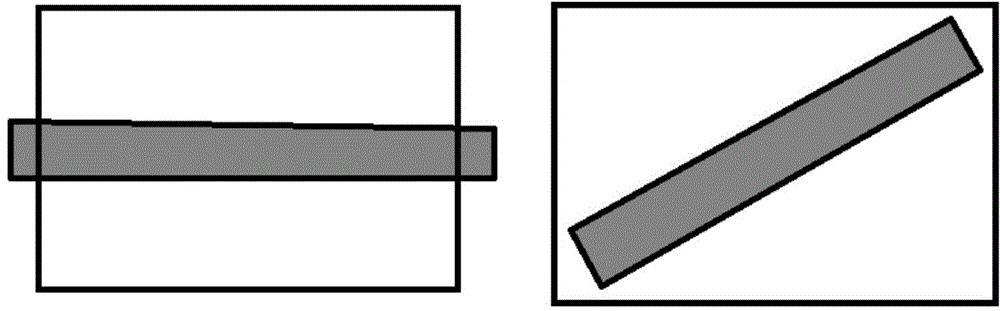

[0069] Example 1, rotation optimization

[0070] E.g image 3 as shown, image 3 The left is the default printing direction of the model (inner rectangle). If the model exceeds the size of the printing volume (outer border), it cannot be printed in the default direction; in the existing technology, the model is considered too large, and the model is directly reduced and then printed in the default direction. While the preferred embodiment of the present invention will automatically try to perform rotation optimization, such as image 3 The right is the optimized printing direction, in this direction, the model can be printed directly without shrinking the model, thus ensuring the ideal printing effect.

[0071] Specifically, in the first preferred embodiment of the present invention, firstly, the printing direction is optimized based on the printing space. The purpose of optimization is to automatically rotate the model and find an optimized angle as a new printing directio...

Embodiment 2

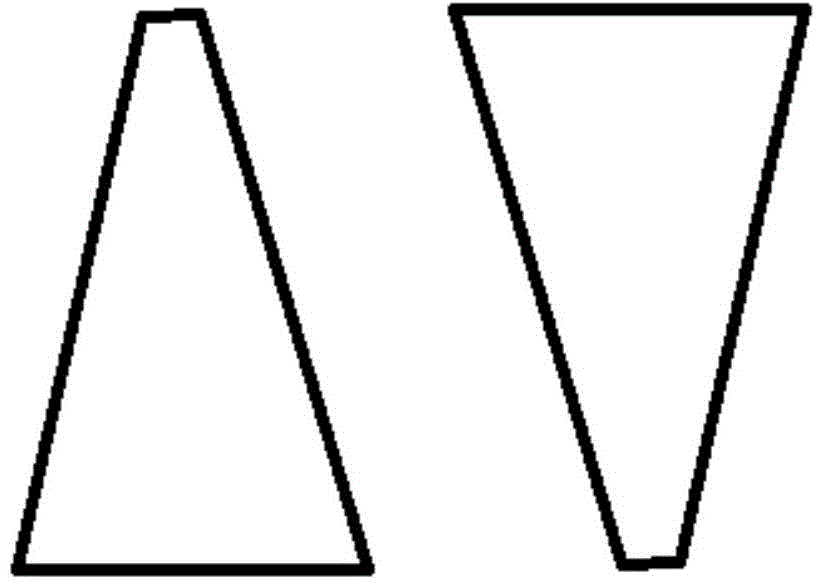

[0083] Embodiment 2, optimization of inclination support

[0084] Such as Figure 4 As shown, when the printed object has a large inclination angle, since the FDM (Fused Deposition Modeling, Fused Deposition Modeling) printing process is always printed from the bottom up, it is necessary to generate additional supports, which use additional consumables, and finally To peel from the object itself wastes consumables while adding extra print time. Figure 4 In the middle left, the large trapezoidal object with an inclination angle above is the object to be printed, and the triangular object below is the support that must be generated; Figure 4 The shape of the support is shown on the right.

[0085] But see further Figure 5 ,same with Figure 4 The object to be printed in, if selected Figure 5 If three-dimensional printing is carried out in the printing direction shown, no additional support system is required for the two printing directions, which can effectively save ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com