Supersonic-velocity hypersonic-velocity gas inlet duct adopting pneumatic unstart control method

A hypersonic air inlet technology, applied in the field of hypersonic air inlets and supersonic aircraft, can solve problems such as doubts about rapid response capability and difficulty in ensuring real-time performance, and achieve a simple structure, small footprint, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

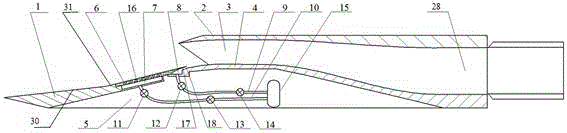

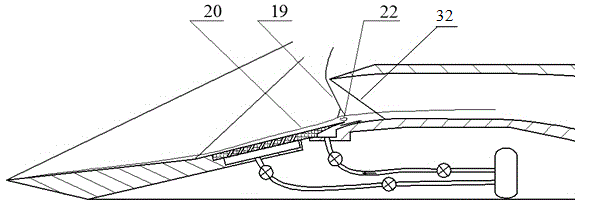

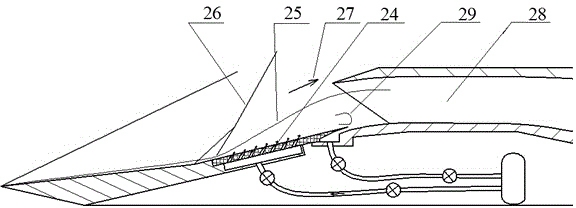

[0017] see Figure 1 to Figure 3 As shown, the present invention discloses a supersonic and hypersonic air intake adopting a pneumatic non-starting control method, comprising an air intake precursor 1, an air intake lip cover 2 installed on the outside of the air intake precursor 1, The inner channel lower wall plate 4 extending backward from the air inlet precursor 1, the multi-slit plate 6 connected between the air inlet precursor 1 and the inner channel lower wall plate 4, and a pneumatic control system. An inner passage 28 is formed between the inner passage lower wall plate 4 and the air inlet lip cover 2 . The lower wall plate 4 of the inner channel and the outer edge of the lip cover 2 of the air inlet form an air inlet 32 . The lower wall plate 4 of the inner channel is provided with a housing chamber 5 for accommodating a pneumatic control system, and a first pressure stabilizing chamber 7 is arranged between the housing chamber 5 and the multi-slit plate 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com