Copper ingot automatic stacking device

An automatic stacking and copper ingot technology, which is applied in the stacking, transportation and packaging of objects, and the unstacking of objects, etc., can solve the problems of inconvenient handling, limited weight, and low efficiency, and achieve high handling efficiency and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

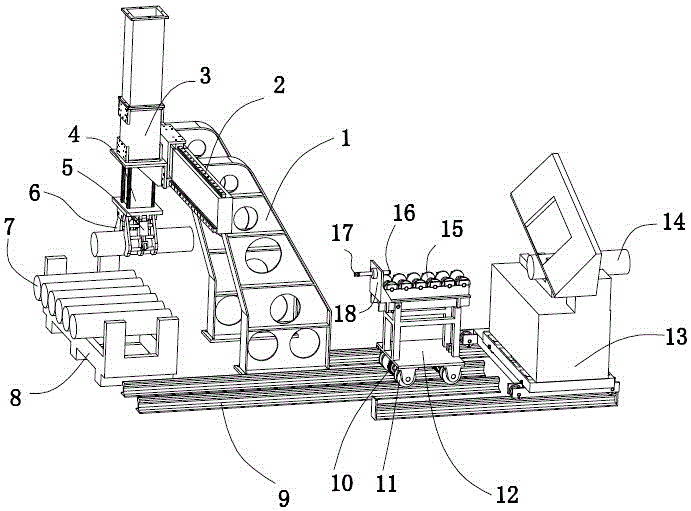

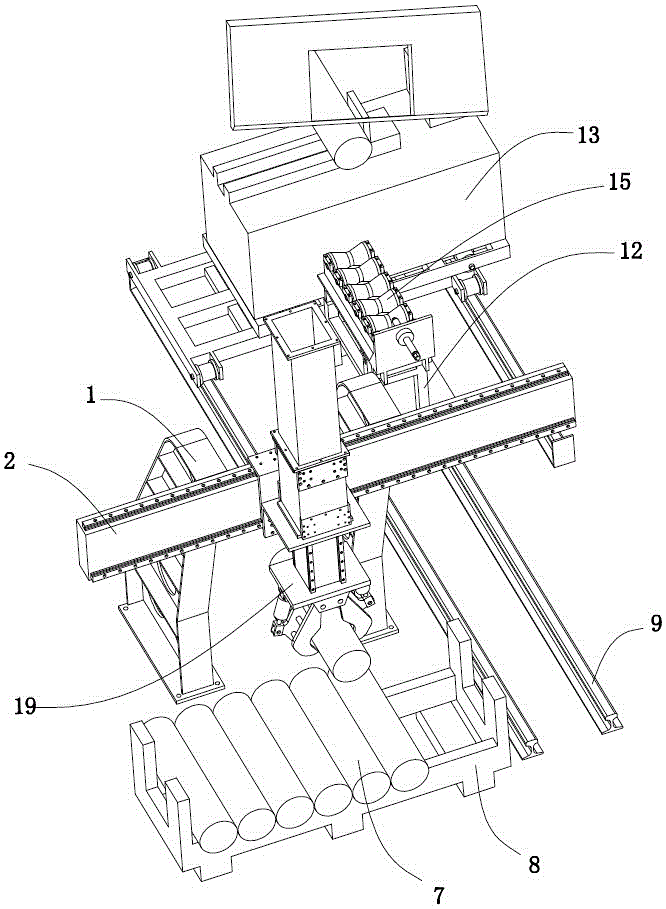

[0022] Embodiment: a kind of automatic stacking device for copper ingots (see attached figure 1 attached figure 2 ), which is set behind the copper cutting equipment 13 as a whole, at a suitable position on the side of the copper ingot automatic stacking device, it includes a manipulator 19 that automatically transports the copper ingots and places them on the shelf in order, and is set between the manipulator and the copper cutting equipment. Automatically moving dolly 12, after the copper material is cut off, the dolly automatically transfers the copper ingot to the handling station.

[0023] A trolley moving guide rail 9 is installed between the manipulator and the copper material cutting equipment, and the upper surface of the guide rail is inclined, and the upper surface height of one end of the guide rail corresponding to the manipulator is lower than the upper surface height of one end of the corresponding copper material cutting equipment of the guide rail. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com