Rake machine and material distributing method thereof

A raking machine and material distribution technology, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of small material accumulation capacity, low warehouse utilization rate, and increased manufacturing cost, so as to improve utilization rate, reduce production cost, and prevent dithering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

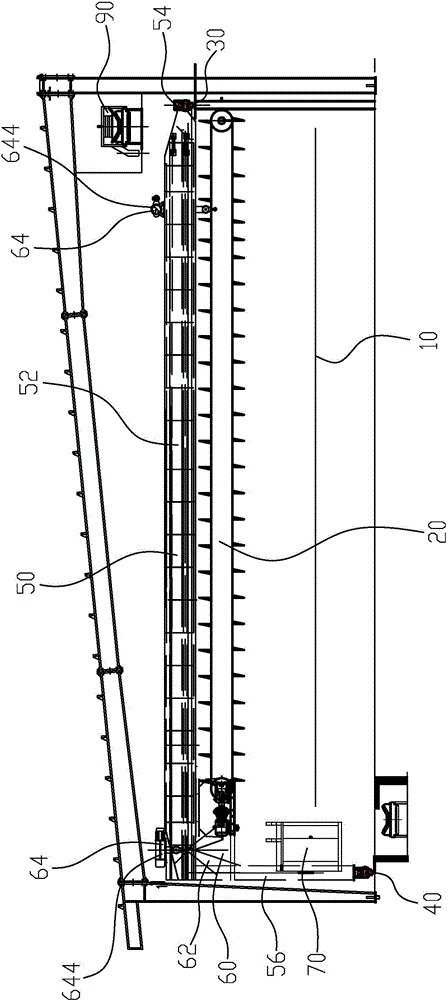

[0028] Please refer to figure 1 , a raking machine of the present invention, comprising: a rake arm mechanism 20 for raking materials on the distributing platform 10; along the length direction of the distributing platform 10 (perpendicular to the direction of the paper), it is arranged on the distributing platform 10 in a height difference The high-level track 30 and the low-level track 40 on both sides; the frame 50 that spans the distribution platform 10 and is used to hang the rake arm mechanism 20, and the two ends of the frame 50 are respectively slidably arranged on the high-level track 30 and the low-level track 40; The frame 50 is used to drive the rake arm mechanism 10 to move vertically and swing up and down; the driver's cab 70 arranged on the frame 50 is used to control the rake machine.

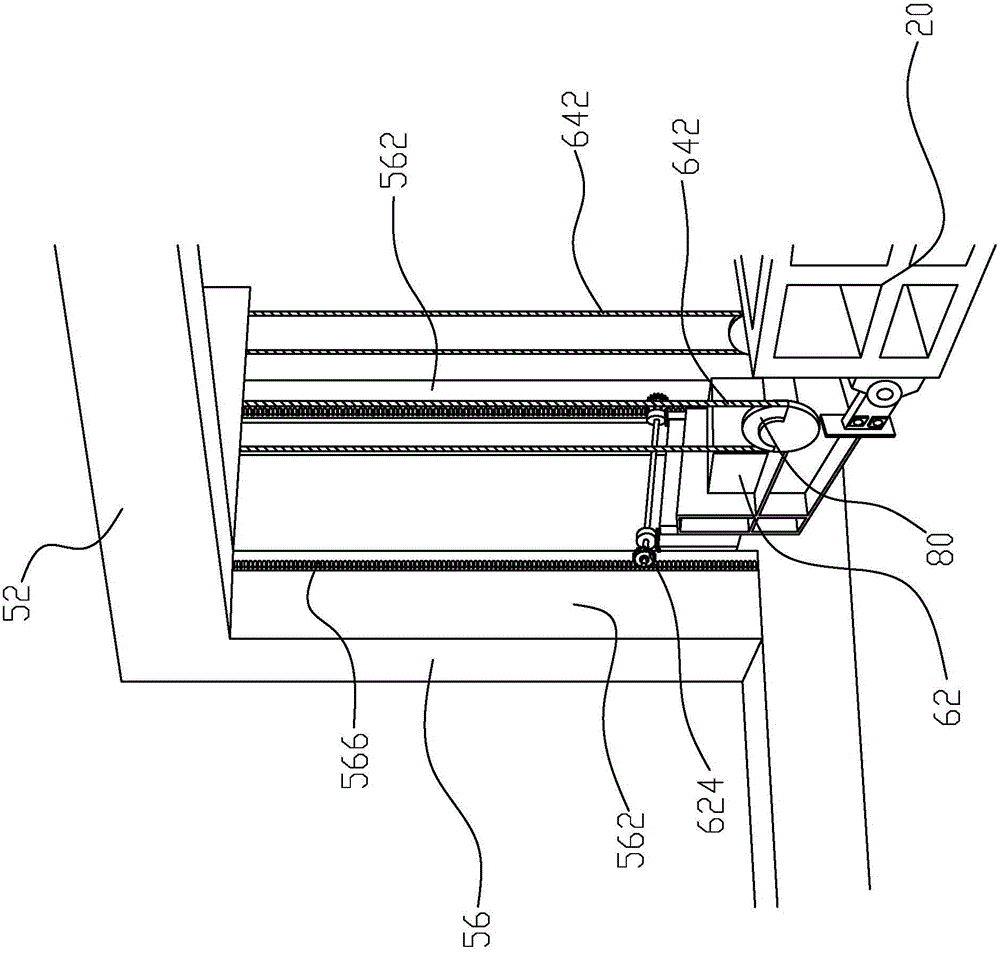

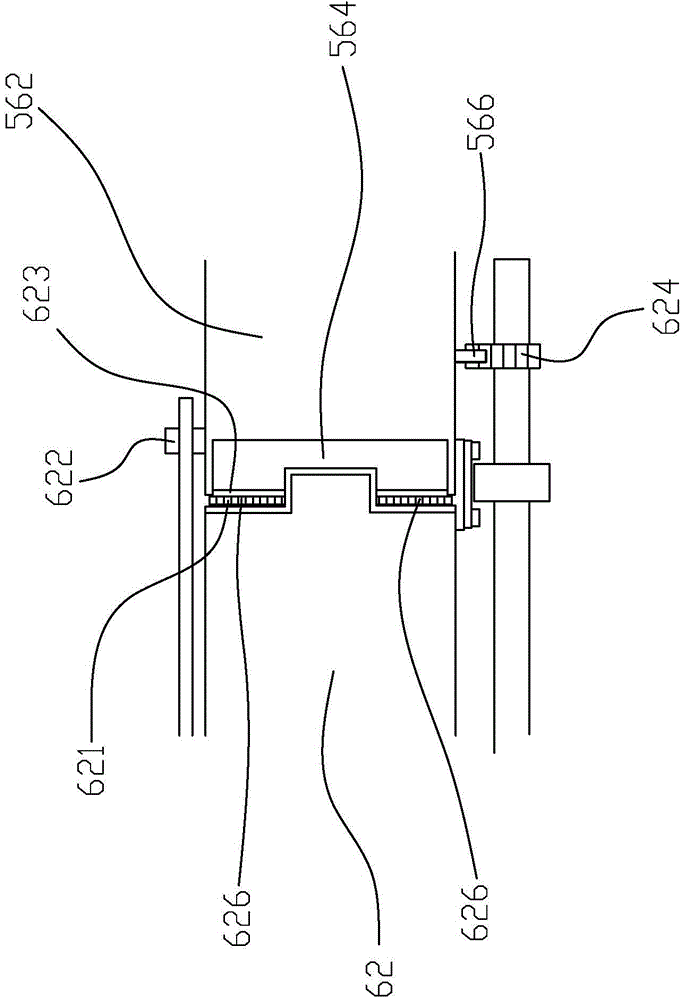

[0029] Please refer to figure 1 with figure 2 , the frame 50 includes a horizontal beam 52 , an upper end beam 54 connected to one end of the horizontal beam 52 , and a porta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com