A method for in-situ preparation of ceramic/carbon composites from hot-pressed organoclay

A carbon composite material, in-situ preparation technology, applied in clay products, other household utensils, household utensils, etc., can solve the problems of uneven dispersion of solid phase reinforcement and complicated sintering process, and achieve low cost, simple process, The effect of improving the strength of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

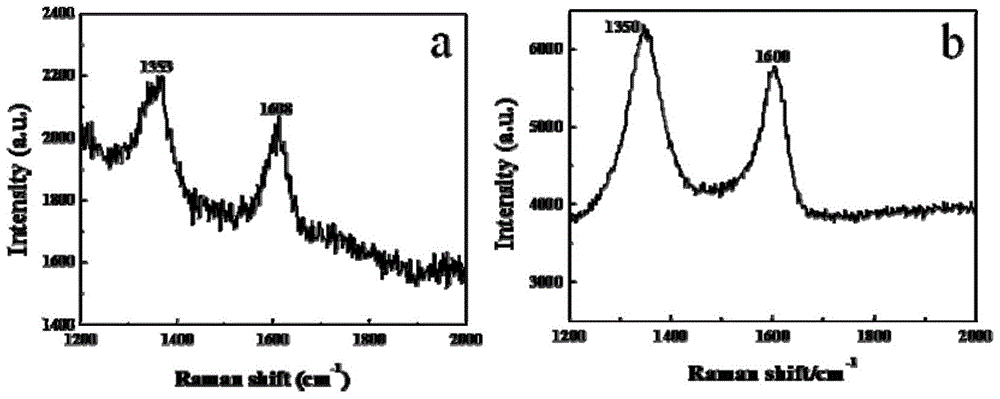

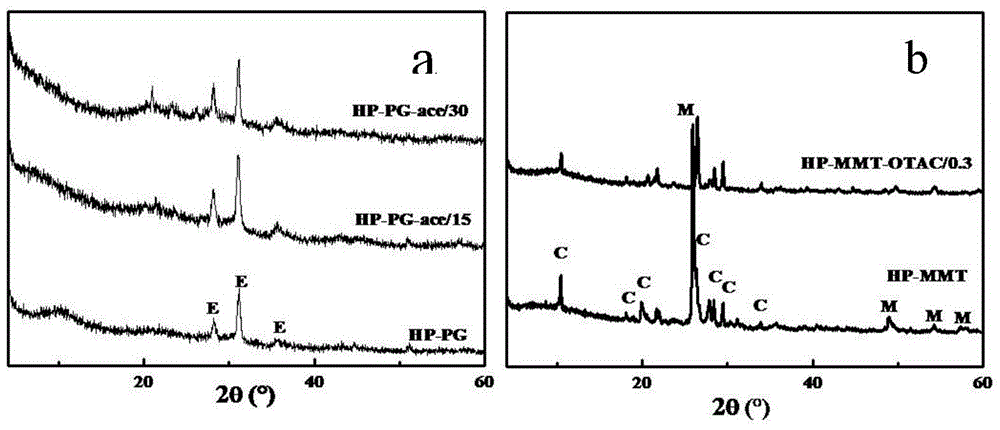

[0022] Example 1 (HP-PG-ace-30)

[0023] In this example, attapulgite clay is used as raw material, and ceramic / carbon composite materials are prepared according to the following steps:

[0024] a1, pulverizing the attapulgite clay and passing through a 200-mesh sieve to obtain attapulgite powder;

[0025] a2. Prepare 240ml of acetamide solution with a mass fraction of 30wt.%. Weigh 12g of attapulgite powder and place it in the acetamide solution. After electric stirring and mixing at room temperature for 80 hours, centrifuge and dry at 60°C for 12 hours to obtain acetamide-modified Attapulgite powder;

[0026] a3. After grinding the acetamide-modified attapulgite powder obtained in step a2 and passing through a 200-mesh sieve, weigh 7g and place it in a graphite mold, and put it into a hot-press furnace together; , raise the temperature from room temperature to 300°C over 1 hour; then under 18MPa pressure, raise the temperature from 300°C to 700°C over 1 hour, then continue...

Embodiment 2

[0029] Example 2 (HP-PG-ace-15)

[0030] In this example, a ceramic / carbon composite material was prepared in the same manner as in Example 1, except that the mass fraction of acetamide solution in step a2 was 15 wt.%. The obtained attapulgite-based ceramic / carbon composite was named HP-PG-ace-15.

[0031] Through the three-point bending test, the bending strength of the attapulgite-based ceramic / carbon composite material is 100 MPa, and the elastic modulus is 63 GPa. The density measured by the Archimedes drainage method is 2.44g / cm 3 , the porosity is 8.86%.

Embodiment 3

[0032] Example 3 (HP-MMT-OTAC-0.1)

[0033] In this embodiment, montmorillonite clay is used as raw material, and the ceramic / carbon composite material is prepared according to the following steps:

[0034] b1, pulverizing the montmorillonite clay and passing through a 200-mesh sieve to obtain montmorillonite powder;

[0035] b2. Weigh 12g of montmorillonite powder and add it to a beaker filled with 240mL of distilled water in advance, mix well to form a uniform suspension, and add 0.1g of octadecyltrimethylammonium chloride (OTAC ), stirred electrically for 2 hours in a constant temperature water bath at 80°C, centrifuged, and dried at 60°C for 12 hours to obtain alkylammonium modified montmorillonite powder;

[0036] b3, after grinding the alkylammonium modified montmorillonite powder obtained in step b2 and passing through a 200 mesh sieve, weigh 7g and place it in a graphite mold for hot pressing, and put it into a hot pressing furnace together; under the protection of Ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com