Textile dyeing and drying system

A drying system and textile technology, applied in textiles and papermaking, textile material processing, textile material processing equipment configuration, etc., can solve the problems of lack of fast and energy-saving drying equipment, save procedures, improve work efficiency, and easily drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

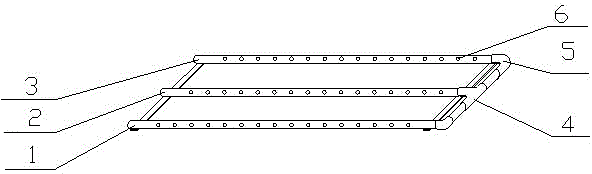

[0039] like figure 1 As shown, a textile dyeing and drying system includes a controller, a temperature sensor, a humidity sensor, a bracket, and three heating tubes arranged on the bracket, which are respectively the first to the third heating tubes, and the first to the third heating tubes Arranged in sequence on the bracket, the three heating tubes communicate with each other, and the adjacent two heating tubes are connected by cascade tubes, between the first heating tube 1 and the cascade tube, and between the third heating tube 3 and the cascade tube Bending connecting pipes 5 are arranged between the pipes, three-way connecting pipes 4 are arranged between the second heating pipe 2 and the cascade pipes, a plurality of hot air holes 6 are arranged on the first to third heating pipes, and the adjacent hot air holes The positions are arranged in a staggered manner, the heating pipe is provided with a plurality of hot air holes, the bracket is fixedly arranged at the outlet...

specific Embodiment 2

[0041] A textile dyeing and drying system, including a controller, a temperature sensor, a humidity sensor, a bracket, and five heating tubes arranged on the bracket, the five heating tubes are arranged on the bracket in sequence, and the five heating tubes are connected to each other. Two adjacent heating pipes are connected by cascading pipes, and the positions of adjacent hot air holes are arranged in a staggered arrangement. The heating pipes are provided with a plurality of hot air holes, and the bracket is fixedly arranged at the outlet of the dyeing machine. The heating pipes A hot air generating device is installed inside or outside, and the hot air is applied to the textile through the hot air hole on the heating pipe. The hot air generating device is connected to the controller, and the temperature sensor and the humidity sensor are installed on the heating pipe. The temperature sensor collects the temperature information of the heating pipe. The humidity sensor colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com