Construction method for overlength jet grouting stiffness core combined pile

A technology of core-core combined piles and rotary grouting piles, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of pile bodies that cannot form the design diameter, weak connection of composite piles, and low-pressure grout injection. , to achieve the effect of enhancing the vertical and horizontal bearing capacity and water-retaining capacity, improving the utilization rate of profiles, and enhancing the overall adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

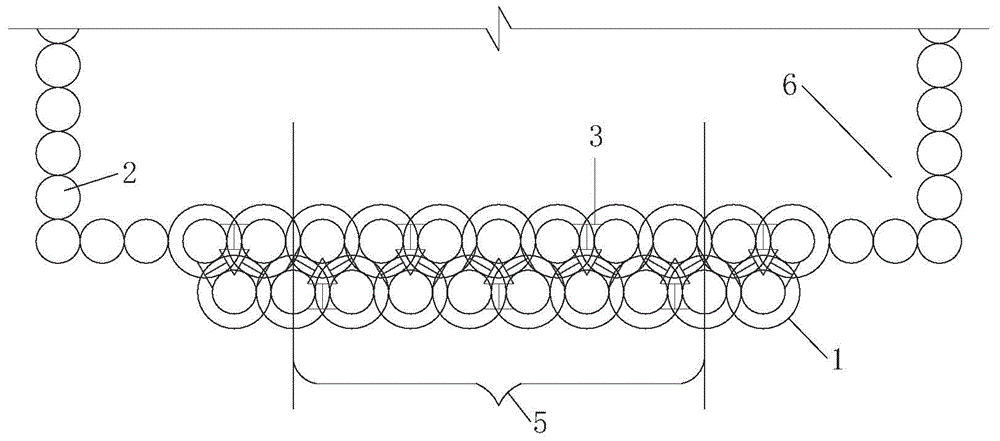

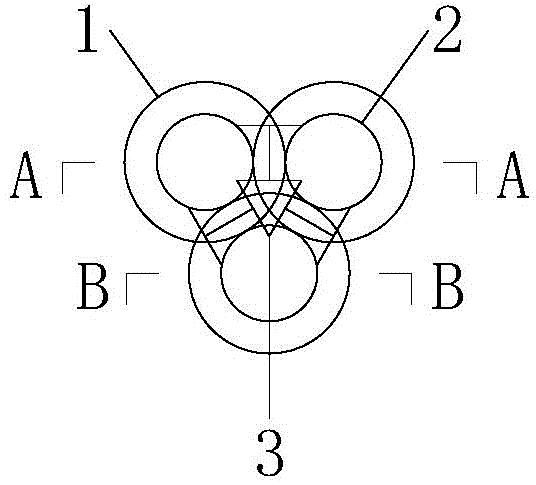

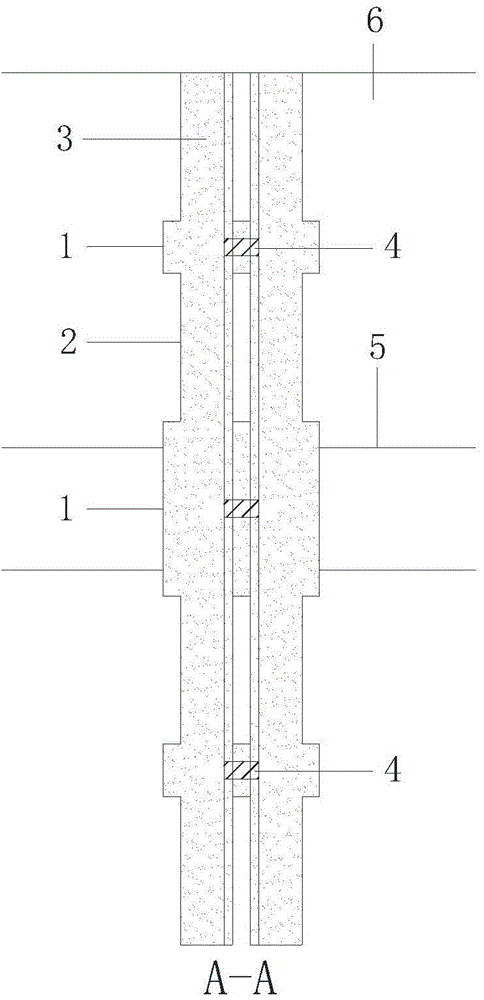

[0025] figure 1 It is the on-site construction layout diagram of the ultra-long rotary grouting dynamic core combined pile of the present invention. figure 2 It is a schematic diagram of three ultra-long jet grouting piles connected as a whole through a steel pile. image 3 yes figure 2 Schematic diagram of section A-A in middle. Figure 4 yes figure 2 Schematic diagram of the middle B-B section. Figure 5 It is a schematic diagram of the connection of section steel piles. Figure 6 yes Figure 5 Schematic diagram of the web connection of the upper and lower I-beams.

[0026] Such as Figure 1-4 The super-long jet-grouting core combined pile shown includes a plurality of super-long jet-grouting piles 2 and steel piles 3, and three super-long jet-grouting piles 2 are connected as a whole through a steel-shaped pile 3. A rotary grouting pile expansion section 1 is arranged on the ultra-long rotary grouting pile corresponding to the underground high pressurized water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com