A Method for Indirect Measurement of Spring Stiffness and Mover Mass of Linear Compressor

A linear compressor and spring stiffness technology, applied in the field of linear compressors, can solve the problems of difficulty in obtaining parameters, affecting the output characteristics of the compressor, inconvenience, etc., and achieve the effect of simple test method, easy operation of test method, and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

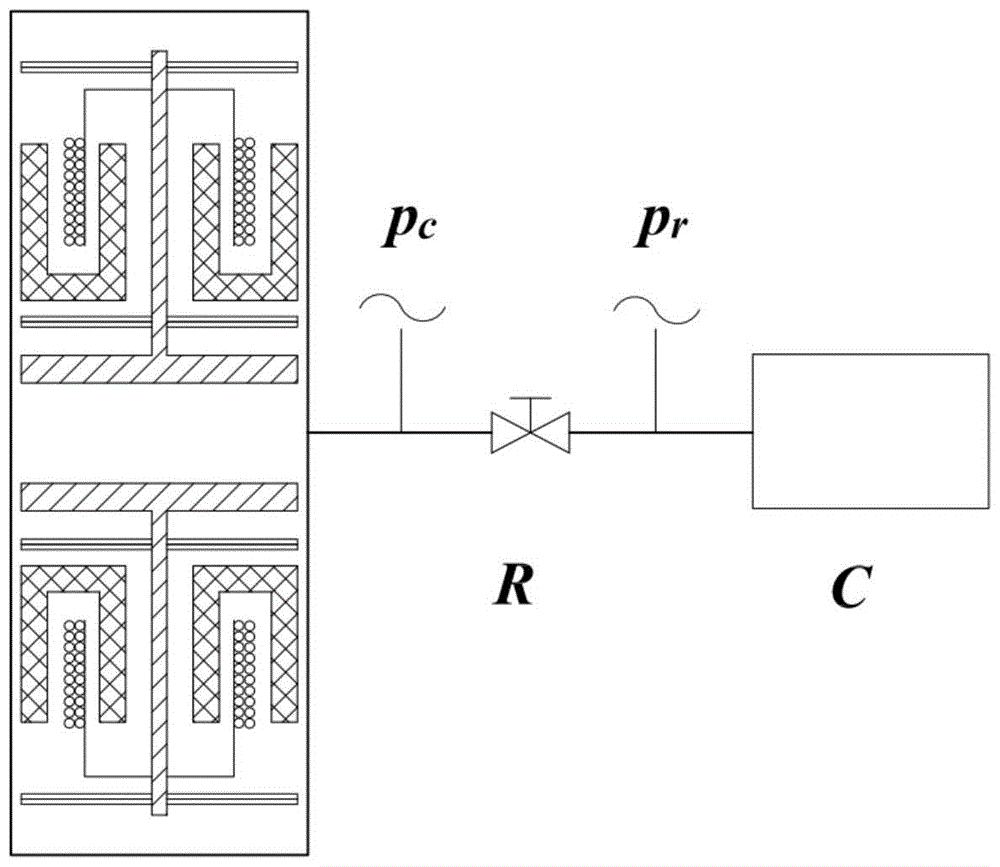

[0035] image 3 Shown is a schematic diagram of the device structure for implementing the method of the present invention for indirectly measuring the spring stiffness of the linear compressor and the quality of the mover. That is, a pipeline is connected to the outlet of the compressor, and a group of valves R and gas storage C are set on the pipeline, and the valves are set close to the outlet of the compressor. Among them, the function of the valve is to provide the real part of the equivalent impedance, and the function of the gas reservoir is to provide the imaginary part of the equivalent impedance. Through some reasonable experimental measurements, the spring stiffness k of the compressor can be obtained by inversion s , and the mass of the mover M are two important parameters that are not easy to measure in practice. In the experiment, a pressure sensor needs to be installed before and after the valve to measure the pressure fluctuation p c and p r ,p c represents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com