Boiler system for monitoring by using cloud server

A cloud server and boiler technology, applied in the field of boiler systems, can solve the problem of inability to flexibly adjust control procedures and parameters, and achieve the effect of size optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

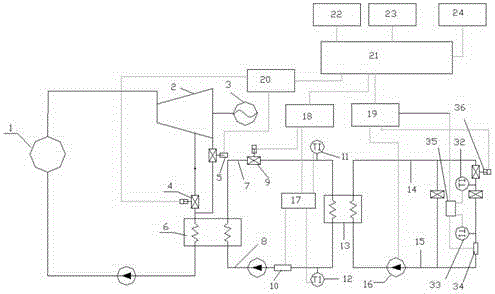

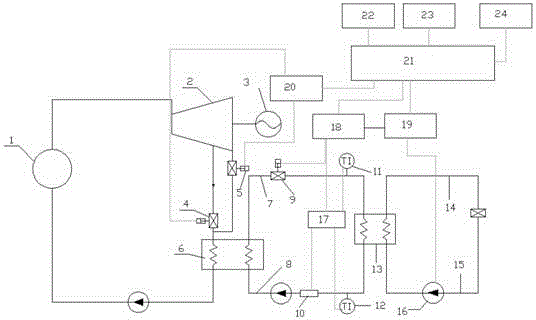

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The invention discloses a boiler system monitored by a cloud server. The boiler system further includes a boiler system programmable controller 20, the programmable controller 20 is connected to a cloud server 21, and the cloud server 21 is connected to a boiler system client 22. The programmable controller 20 transmits the measured data to the cloud server 21, and then transmits the measured data to the boiler system client 22 through the cloud server 21, and the client 22 can obtain the operation information of the boiler system in time.

[0036] Preferably, the operation information includes at least one of the air extraction volume of the steam turbine, the opening of the air extraction valve of the steam turbine, the rotational speed of the steam turbine, the power generation, the water intake of the boiler, and the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com