Temperature measurement device for hearth workpiece surface and temperature measurement method

A temperature measuring device, a technology for the surface of a workpiece, which is applied in measuring devices, radiation pyrometry, optical radiation measurement, etc. Large error and other problems, to achieve the effect of filtering out the temperature shielding effect, protecting from overheating and burning out, and accurately measuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is further elaborated:

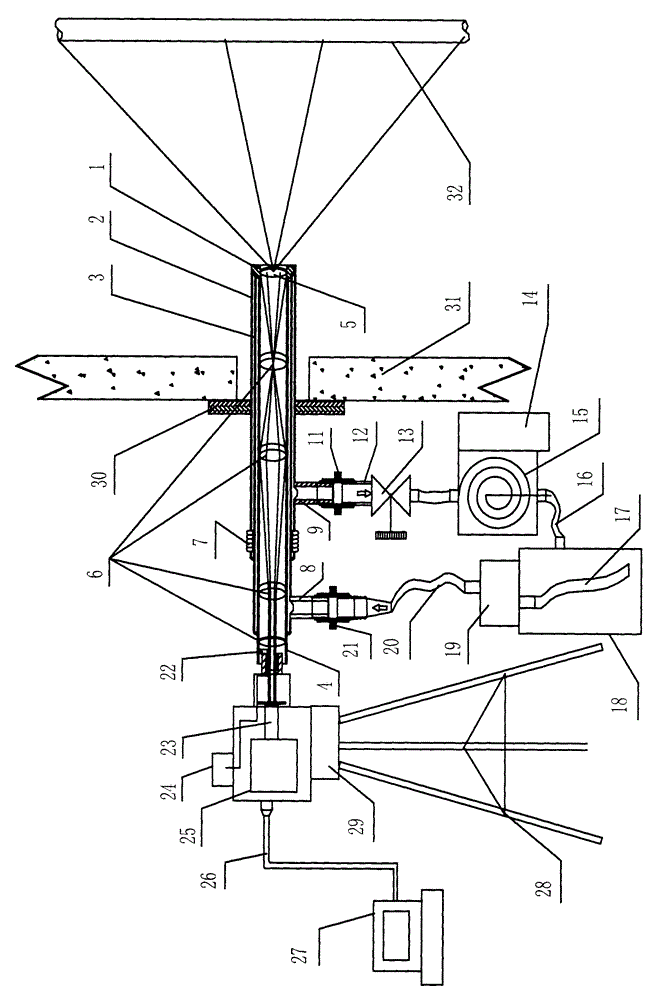

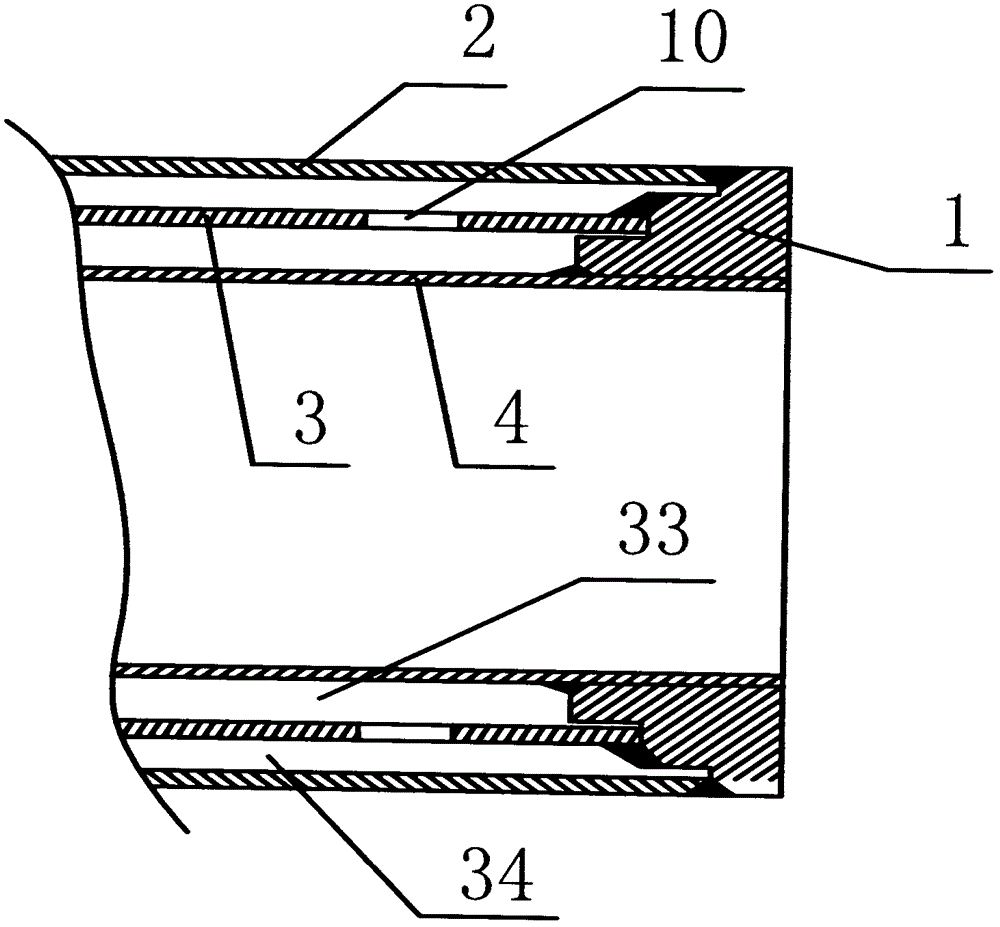

[0030] like figure 1 As shown, a furnace workpiece surface temperature measuring device provided by the present invention is mainly composed of an endoscope temperature measuring probe, a circulating cooling system, a thermal imaging system, a terminal thermal image processing system and a support adjustment system; one end of the thermal imaging system is connected to the endoscope The mirror temperature measuring probe is connected, and the other end is connected to the terminal thermal image processing system. The thermal imaging system is installed and fixed on the support adjustment system; the endoscope temperature measuring probe is equipped with a circulating water inlet and a circulating water outlet, and the circulating cooling system passes through the pipeline. They are respectively connected with the circulating water inlet and the circulating water outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com